putputman

Senior Member

- Joined

- Nov 22, 2008

- Messages

- 600

- Reaction score

- 55

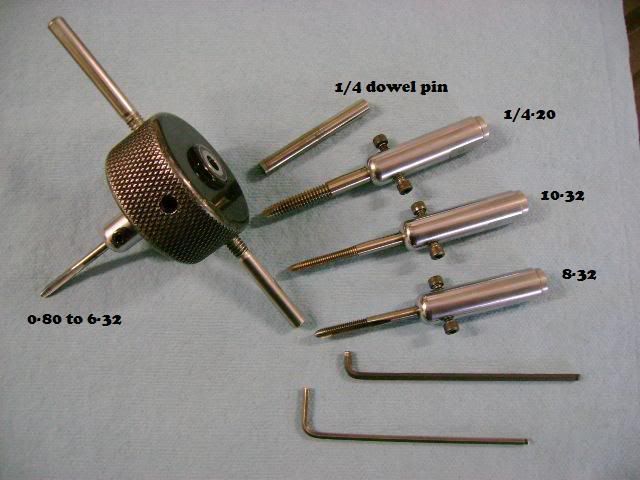

This might be a good project for those who are just starting in the trade or hobby. My mentor had me make this tapping tool over 45 years ago and I still use it very often. It is a tapping tool that can be used in the mill or lathe.

Most taps are broken by bending rather than torque. This tool supports the tap so it can't be bent. I am not saying I haven't broken taps, but I can count on one hand the number of taps I have broken when using this tool. Most of the taps I have broken are done with a t-handle tapping tool.

The 1/4 inch dowel pin is chucked in the mill or lathe and the tapping tool is a slip fit on the tap inserts. On the mill you turn the tap in by hand. In the lathe you can turn the tap by hand or use power & hold the tapping tool from turning. Either way, you have a lot of feel for the torque. On real small taps I remove the handle & hold the knurled knob.

The tool consists of a hand or knob and 4 inserts. The inserts are held in place with a single set screw.

The smallest insert covers taps from 0-80 to 6-32 in both standard & fine threads. The other 3 are for 8-32, 10-32, & 1/4-20 & their equivalents in coarse threads.

I will put some prints in the download section for anyone that might be interested in making this tool.

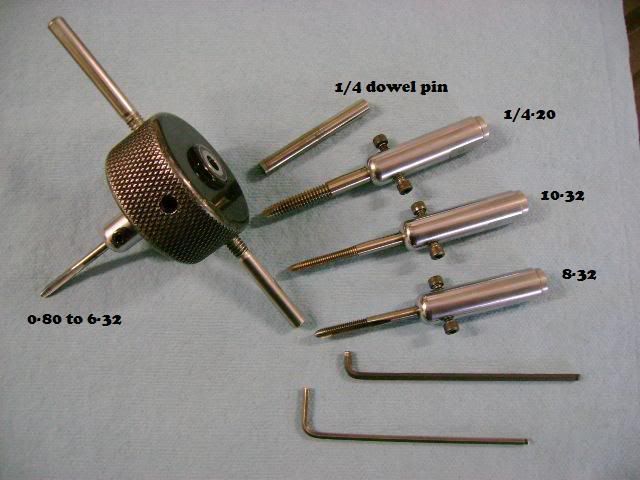

Most taps are broken by bending rather than torque. This tool supports the tap so it can't be bent. I am not saying I haven't broken taps, but I can count on one hand the number of taps I have broken when using this tool. Most of the taps I have broken are done with a t-handle tapping tool.

The 1/4 inch dowel pin is chucked in the mill or lathe and the tapping tool is a slip fit on the tap inserts. On the mill you turn the tap in by hand. In the lathe you can turn the tap by hand or use power & hold the tapping tool from turning. Either way, you have a lot of feel for the torque. On real small taps I remove the handle & hold the knurled knob.

The tool consists of a hand or knob and 4 inserts. The inserts are held in place with a single set screw.

The smallest insert covers taps from 0-80 to 6-32 in both standard & fine threads. The other 3 are for 8-32, 10-32, & 1/4-20 & their equivalents in coarse threads.

I will put some prints in the download section for anyone that might be interested in making this tool.