deere_x475guy

Well-Known Member

Thought I would share this with everyone. This is a ring roller I built a year ago or so. The basic plans are from the Model Engineer magazine and I used Corel Draw to rearrange the holes so I could use the stock I had on hand.

Here's a pic of all the parts laid out:

Here it is all assembled with a ring I rolled out of 1/8" stock. This is the absolute heaviest stuff I would ever want to roll with this little guy.

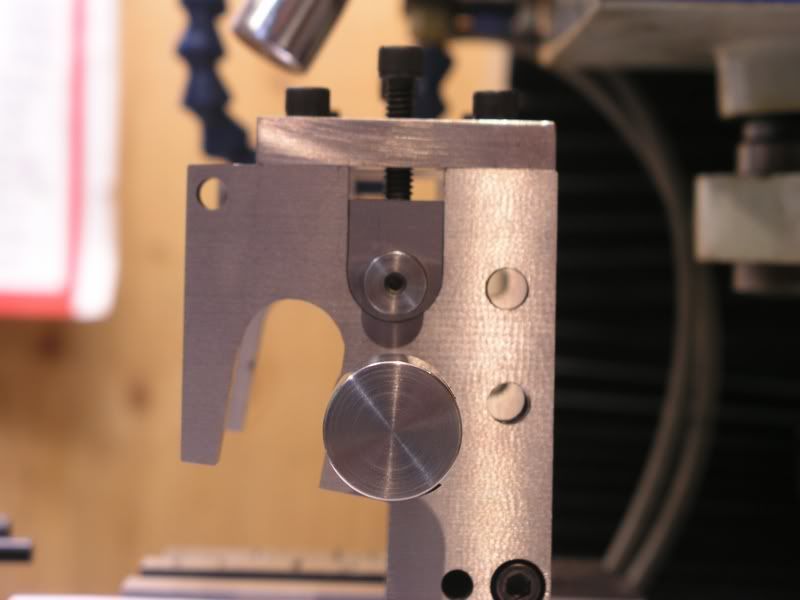

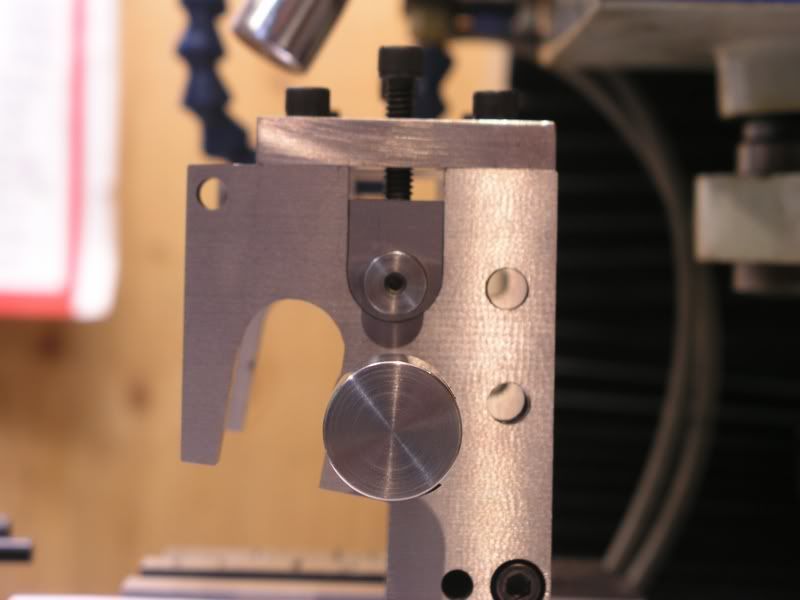

I wasn't real happy with the radius I got with the first set of bearing blocks so I used one of Marv's programs (rounder) and cut it on the mill with a 1/2" ball end mill. This is what the fit looked like when I was done.

Here is a sample out put from Marv's "Rounder" program. I know there are other ways of doing this but I thought I would give this a try....and I needed to test out the new DRO ;D ;D

Workpiece radius = 0.500 in

Ball mill diameter = 0.500 in

A = (R+r)*sin(theta)

B = (R+r)*cos(theta)

C = (R+r)*(1 - sin(theta))

D = (R+r)*(1 - cos(theta))

ANGLE A B C D

0.0 0.000 0.750 0.750 0.000

5.0 0.065 0.747 0.685 0.003

10.0 0.130 0.739 0.620 0.011

15.0 0.194 0.724 0.556 0.026

20.0 0.257 0.705 0.493 0.045

25.0 0.317 0.680 0.433 0.070

30.0 0.375 0.650 0.375 0.100

35.0 0.430 0.614 0.320 0.136

40.0 0.482 0.575 0.268 0.175

45.0 0.530 0.530 0.220 0.220

50.0 0.575 0.482 0.175 0.268

55.0 0.614 0.430 0.136 0.320

60.0 0.650 0.375 0.100 0.375

65.0 0.680 0.317 0.070 0.433

70.0 0.705 0.257 0.045 0.493

75.0 0.724 0.194 0.026 0.556

80.0 0.739 0.130 0.011 0.620

85.0 0.747 0.065 0.003 0.685

90.0 0.750 -0.000 0.000 0.750

Oh yea...almost forgot. The two empty holes you see are threaded for posts so I can add gears to this if I want to.

Here's a pic of all the parts laid out:

Here it is all assembled with a ring I rolled out of 1/8" stock. This is the absolute heaviest stuff I would ever want to roll with this little guy.

I wasn't real happy with the radius I got with the first set of bearing blocks so I used one of Marv's programs (rounder) and cut it on the mill with a 1/2" ball end mill. This is what the fit looked like when I was done.

Here is a sample out put from Marv's "Rounder" program. I know there are other ways of doing this but I thought I would give this a try....and I needed to test out the new DRO ;D ;D

Workpiece radius = 0.500 in

Ball mill diameter = 0.500 in

A = (R+r)*sin(theta)

B = (R+r)*cos(theta)

C = (R+r)*(1 - sin(theta))

D = (R+r)*(1 - cos(theta))

ANGLE A B C D

0.0 0.000 0.750 0.750 0.000

5.0 0.065 0.747 0.685 0.003

10.0 0.130 0.739 0.620 0.011

15.0 0.194 0.724 0.556 0.026

20.0 0.257 0.705 0.493 0.045

25.0 0.317 0.680 0.433 0.070

30.0 0.375 0.650 0.375 0.100

35.0 0.430 0.614 0.320 0.136

40.0 0.482 0.575 0.268 0.175

45.0 0.530 0.530 0.220 0.220

50.0 0.575 0.482 0.175 0.268

55.0 0.614 0.430 0.136 0.320

60.0 0.650 0.375 0.100 0.375

65.0 0.680 0.317 0.070 0.433

70.0 0.705 0.257 0.045 0.493

75.0 0.724 0.194 0.026 0.556

80.0 0.739 0.130 0.011 0.620

85.0 0.747 0.065 0.003 0.685

90.0 0.750 -0.000 0.000 0.750

Oh yea...almost forgot. The two empty holes you see are threaded for posts so I can add gears to this if I want to.