deere_x475guy

Well-Known Member

LOL...not real sure what to call this tool so the subject line is my best guess. This is a very close knock off to what Mcgyver used to make his bending dies. Oh..yea...I will be posting a build on bending dies in this section as I get the parts made up. Anyway here is my version of the tool thingy that cuts a radius on your lathe.

I started out with a piece of 5/8ths drill rod then milled all 4 sides to give me flats. Then I set the part to approx. 15 degrees and drilled, reamed to 1/4" dia.

Next I rotated the part 90 degrees and cut a slot. After cutting the slot I drilled and taped for a clamp screw.

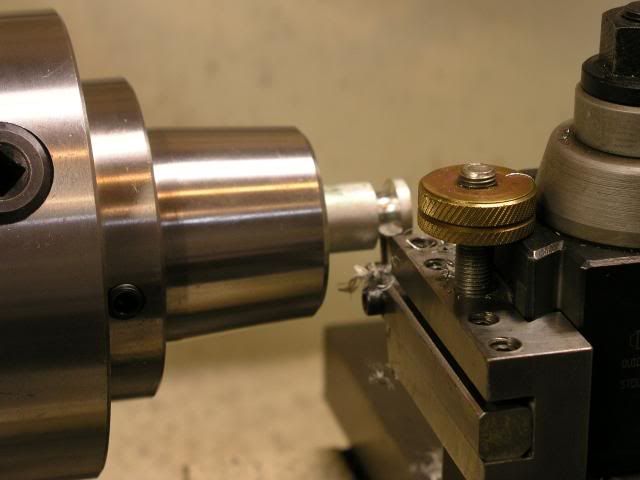

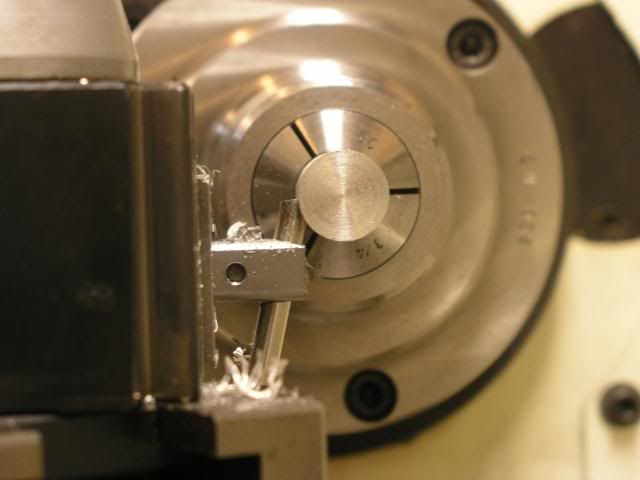

Here is the new lathe tool in a holder I built about 5 years ago. I think this holder is probably the 5th project I had completed.

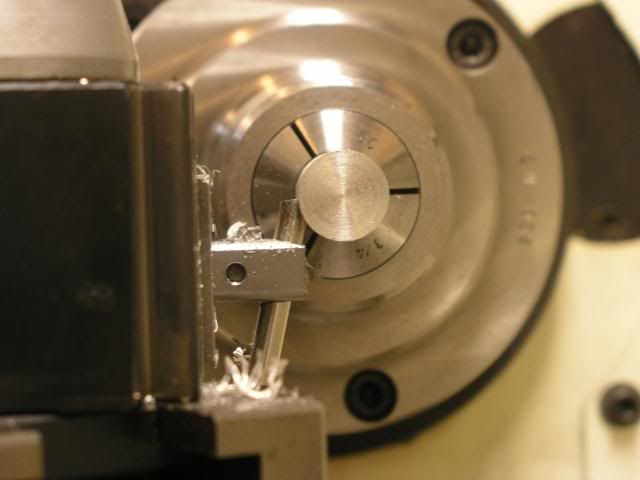

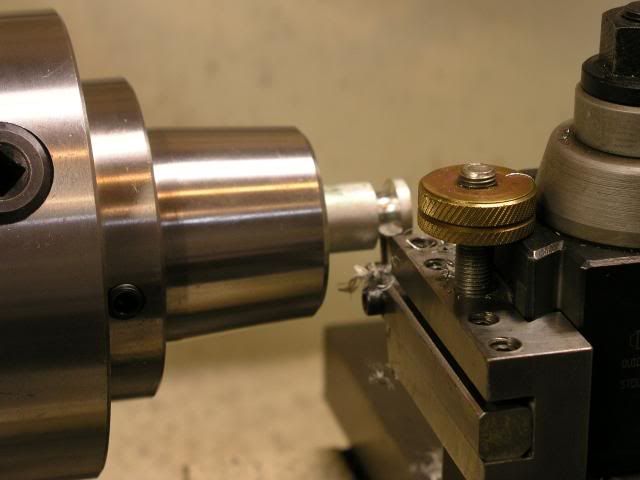

Here are a couple of action shots. I was really pleased with the way this cut my aluminum die. Not sure how well it's going to work on mild steel.

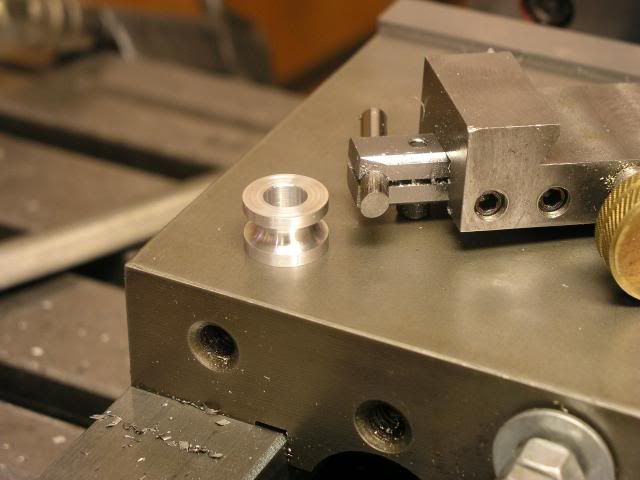

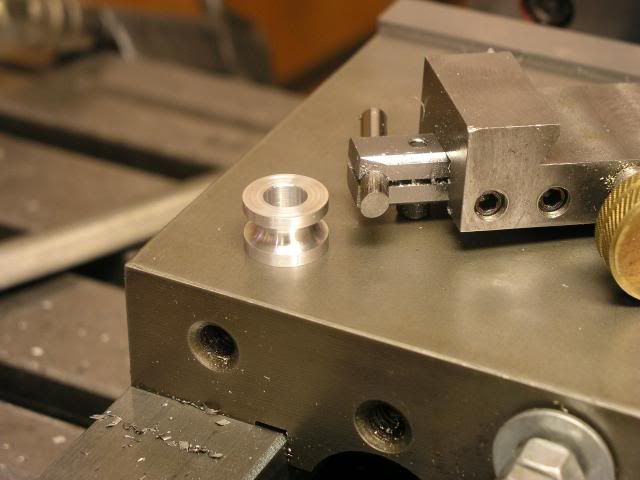

And here you see the tool and the die.. ))

))

The bit was ground with about 7 degrees back rake on aluminum I didn't have any chatter at all...just a nice clean finish. ;D ;D

Happy New Year all...

Bob

I started out with a piece of 5/8ths drill rod then milled all 4 sides to give me flats. Then I set the part to approx. 15 degrees and drilled, reamed to 1/4" dia.

Next I rotated the part 90 degrees and cut a slot. After cutting the slot I drilled and taped for a clamp screw.

Here is the new lathe tool in a holder I built about 5 years ago. I think this holder is probably the 5th project I had completed.

Here are a couple of action shots. I was really pleased with the way this cut my aluminum die. Not sure how well it's going to work on mild steel.

And here you see the tool and the die..

The bit was ground with about 7 degrees back rake on aluminum I didn't have any chatter at all...just a nice clean finish. ;D ;D

Happy New Year all...

Bob