small.planes

Member

- Joined

- Oct 7, 2008

- Messages

- 8

- Reaction score

- 0

Evening,

First post here, so I thought Id make it a useful tool thingy

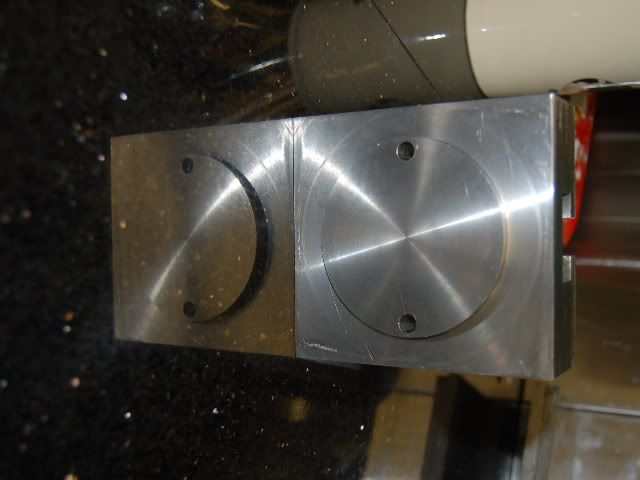

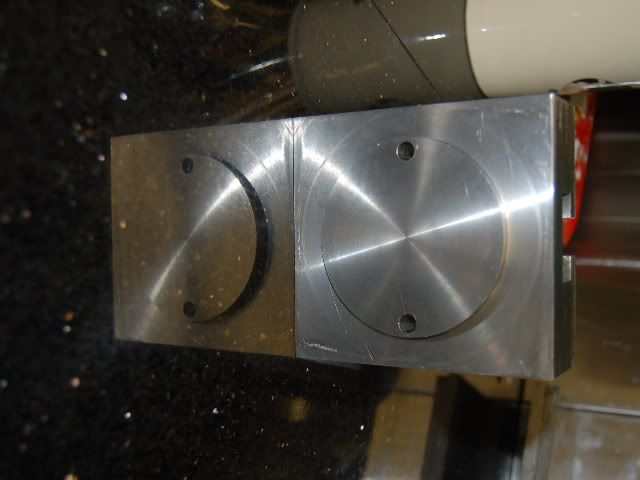

It a block that replaces the top slide from my Harrison L5. I dont use the topslide much, and removing a slide should help with the rigidity.

Its been sat clamped to my mill table (Love having a big mill, can leave jobs setup and still use the rest of it ) for a couple of weeks, as I needed a 13mm (1/2" actually) collet to hold the woodruff cutter I borrowed (Thanks John) to press into service as a T Slot cutter.

This is the scariest cut Ive made so far on my mill, the slot is full width of the (borrowed) cutter, the small part of the T is 16.5mm across. The block is a piece of Thyroplast 2085 I picked up, its a stainless mould steel. Its hard, but it does polish up nicely though.

Dave

First post here, so I thought Id make it a useful tool thingy

It a block that replaces the top slide from my Harrison L5. I dont use the topslide much, and removing a slide should help with the rigidity.

Its been sat clamped to my mill table (Love having a big mill, can leave jobs setup and still use the rest of it ) for a couple of weeks, as I needed a 13mm (1/2" actually) collet to hold the woodruff cutter I borrowed (Thanks John) to press into service as a T Slot cutter.

This is the scariest cut Ive made so far on my mill, the slot is full width of the (borrowed) cutter, the small part of the T is 16.5mm across. The block is a piece of Thyroplast 2085 I picked up, its a stainless mould steel. Its hard, but it does polish up nicely though.

Dave