You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rotary Valve Engine

- Thread starter 1Kenny

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

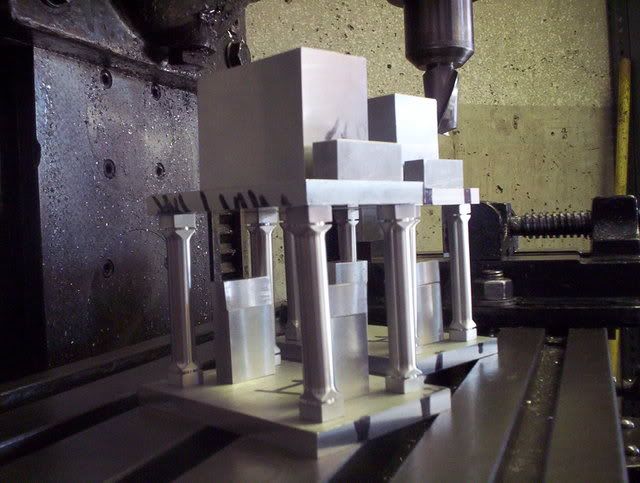

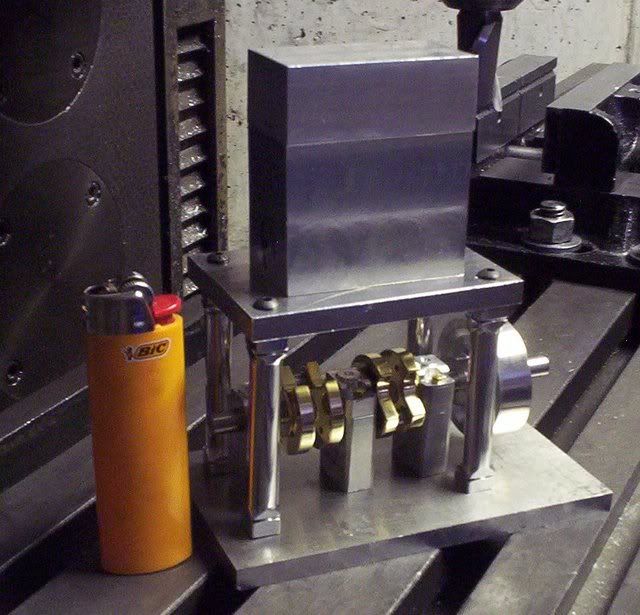

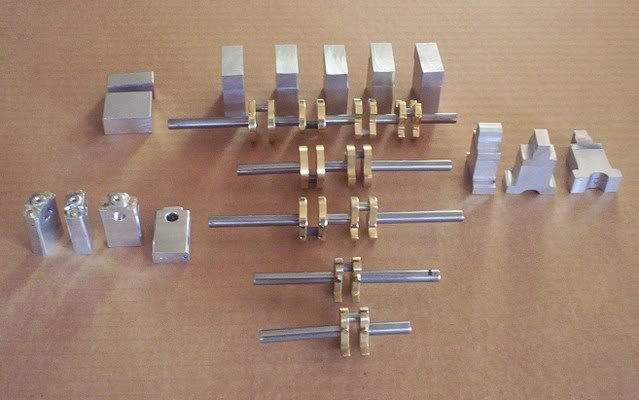

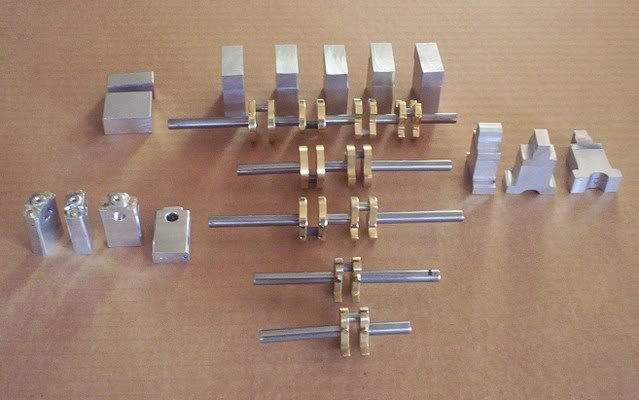

Now I have a big problem. There are many more parts to make due to me not being able to control myself. Once I started making the different crankshaft, I couldn't stop. So the next step is to make more main shaft supports. The lower single cylinder cranks are the split type with a 2-56 squeeze bolts. On the lower two cylinder crank I used 2-56 set screws to hold the shafts. The next two cranks are press fit to the shafts as is the four cylinder crank.

They are all a little different and that is making it fun.

Kenny

They are all a little different and that is making it fun.

Kenny

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

I am having a heck of a time planning my first bar stock engine. This is not helping me by posting this. ??? Not that it is a bad thing. ;D

Looking good!

[Highjack] I have been tossing this one, a few of Elmer's engines around and a couple of Jerry Howell's engines around for my first. Gonna wait until I finish tooling up the lathe first. [\Highjack]

I love to see build logs of engines. keep it up.

Eric

Looking good!

[Highjack] I have been tossing this one, a few of Elmer's engines around and a couple of Jerry Howell's engines around for my first. Gonna wait until I finish tooling up the lathe first. [\Highjack]

I love to see build logs of engines. keep it up.

Eric

Thanks for the compliment, Rick.

Eric,

It took me over a month to decide on this engine. I wanted to build one that had columns and an entablature involved. A big thing I have learned here is not to be worried about changing things on the plans. I have been looking at quite a few old engineering and machine books to get ideas for different machine bases that can be applied to the crankshaft main bearing supports. Planing is taking me longer than making the parts.

Kenny

Eric,

It took me over a month to decide on this engine. I wanted to build one that had columns and an entablature involved. A big thing I have learned here is not to be worried about changing things on the plans. I have been looking at quite a few old engineering and machine books to get ideas for different machine bases that can be applied to the crankshaft main bearing supports. Planing is taking me longer than making the parts.

Kenny

dparker

In Rembrance 8/2021

- Joined

- Aug 24, 2007

- Messages

- 218

- Reaction score

- 5

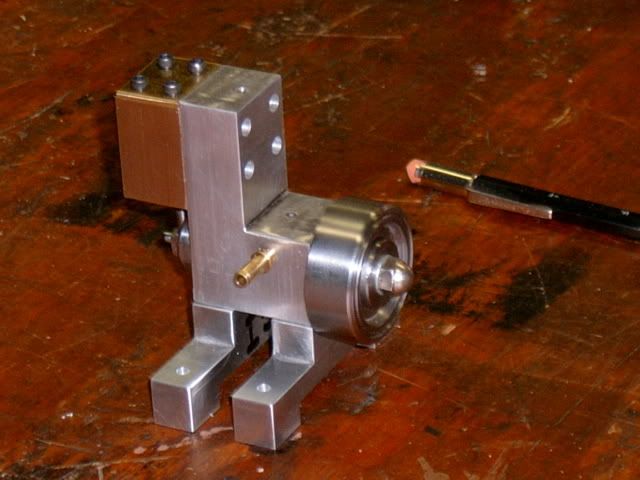

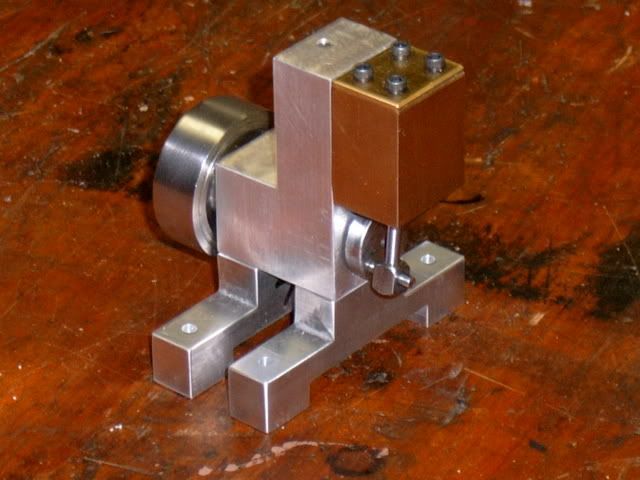

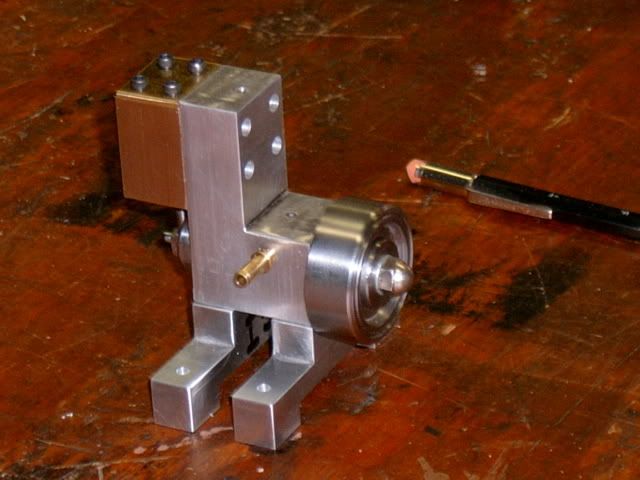

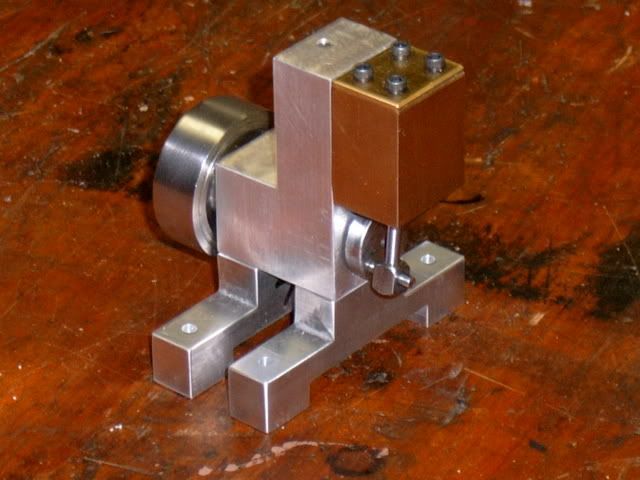

Hello All: I finally got out of the chair in front of the computer and reading this forum and did something. When I received the last Machinist's Workshop magazine I liked the cover photo. I looked at the article by Walter Yetman and his instructions for building the engine, it looked like a nice quick weekend build. Well, being slow and trying to use what stock I had on hand and taking a little liberty with the design it only took me a week for a nice simple engine build.

I made the block a little longer and pressed in a brass tube for the bearing so the end leakage should be less, and used a piece of brass flat stock for the head. I should make some gaskets for the head and block to the cylinder.

Fun build! The engine runs well after breakin and still needs to be mounted on a base.

don

I made the block a little longer and pressed in a brass tube for the bearing so the end leakage should be less, and used a piece of brass flat stock for the head. I should make some gaskets for the head and block to the cylinder.

Fun build! The engine runs well after breakin and still needs to be mounted on a base.

don

Similar threads

- Replies

- 3

- Views

- 663

- Replies

- 12

- Views

- 1K