Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

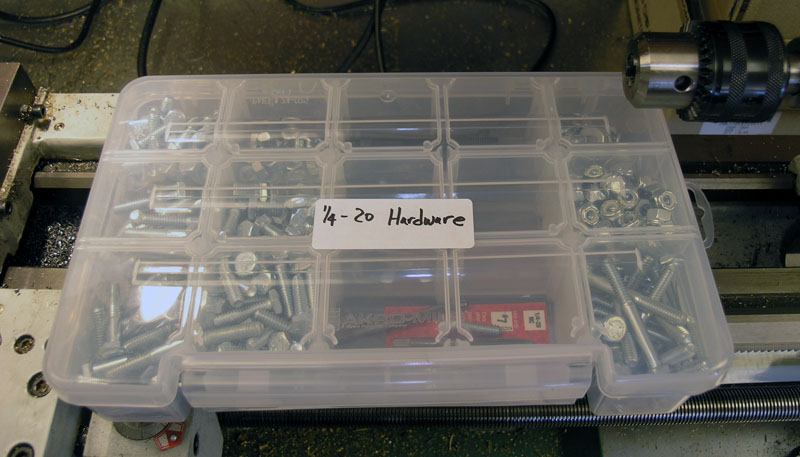

Proper organization sure makes projects go smoother. You can spend more time doing and not so much time looking.

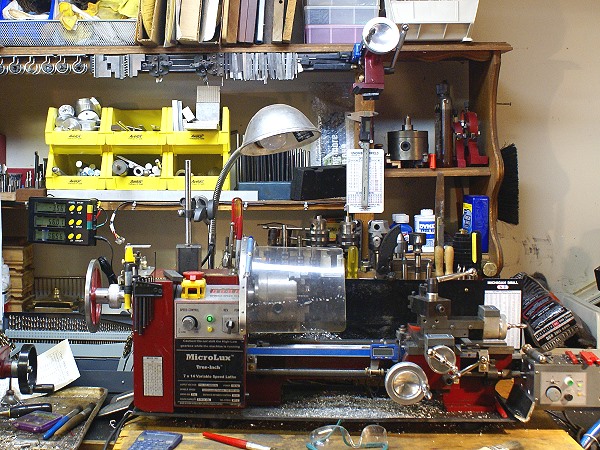

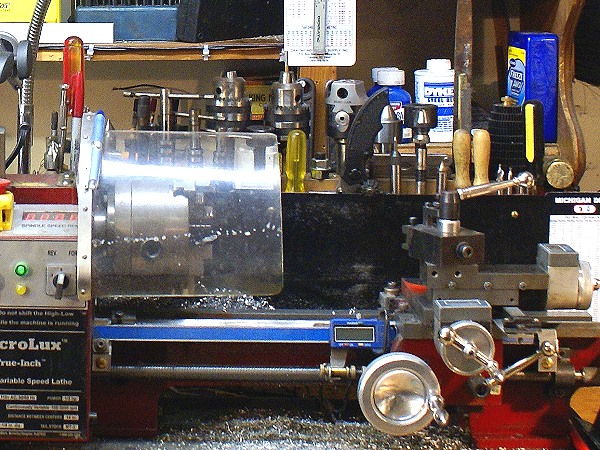

It has been said that one picture is worth a thousand words. Maybe this picture is worth a couple hundred.

There is another saying: A place for everything and everything in it's place.

It has been said that one picture is worth a thousand words. Maybe this picture is worth a couple hundred.

There is another saying: A place for everything and everything in it's place.