Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

The more tricks and tips presented, the more flexible we all become as we encounter a tricky bit of challenging metal work. It definitely encourages mentally stepping outside of the box and increases one's comfort zone.

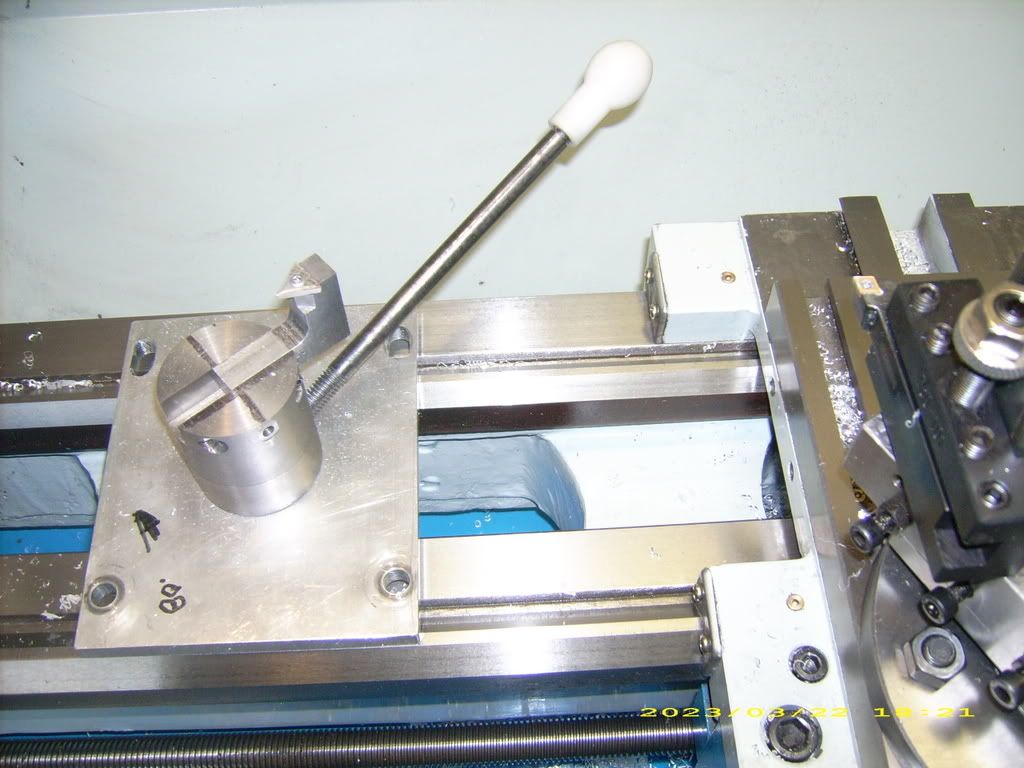

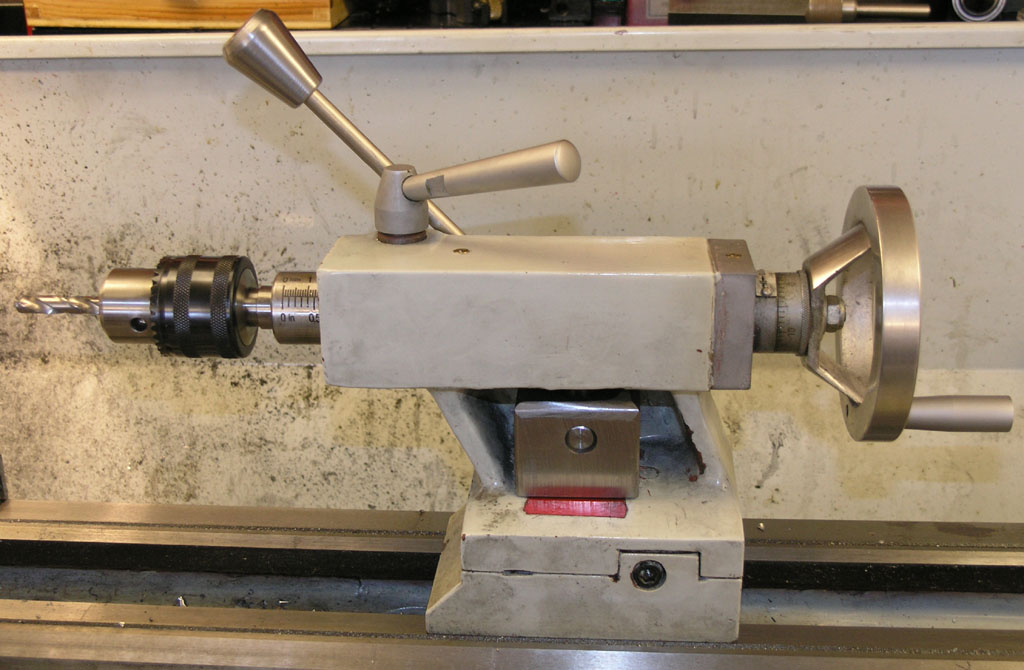

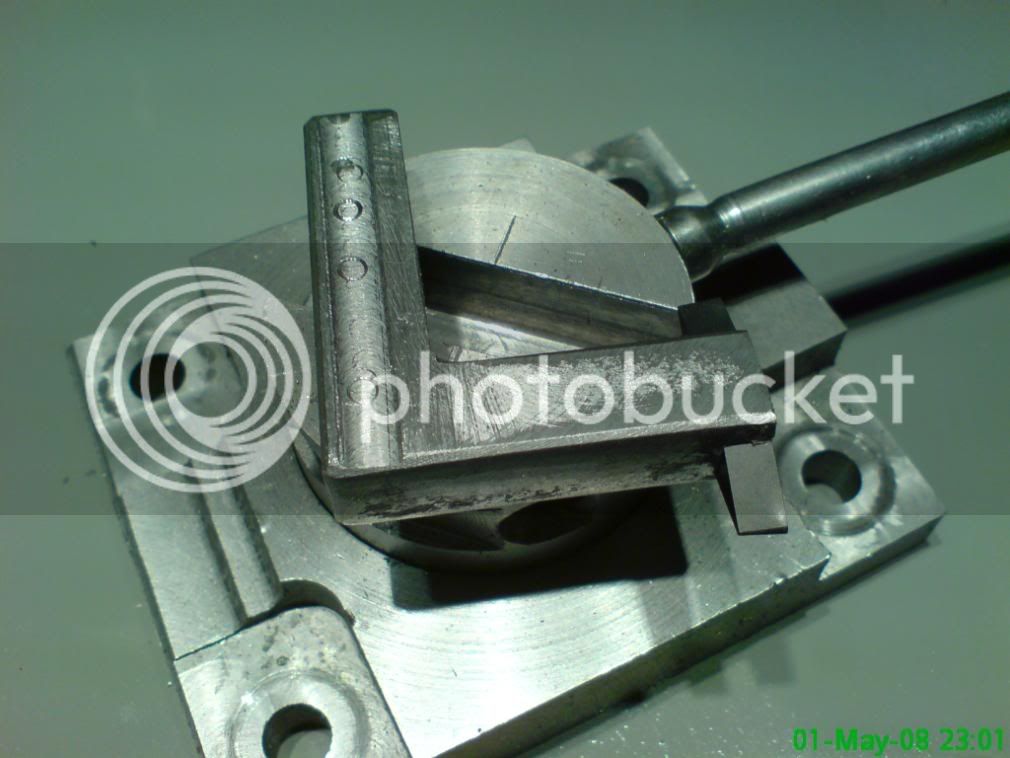

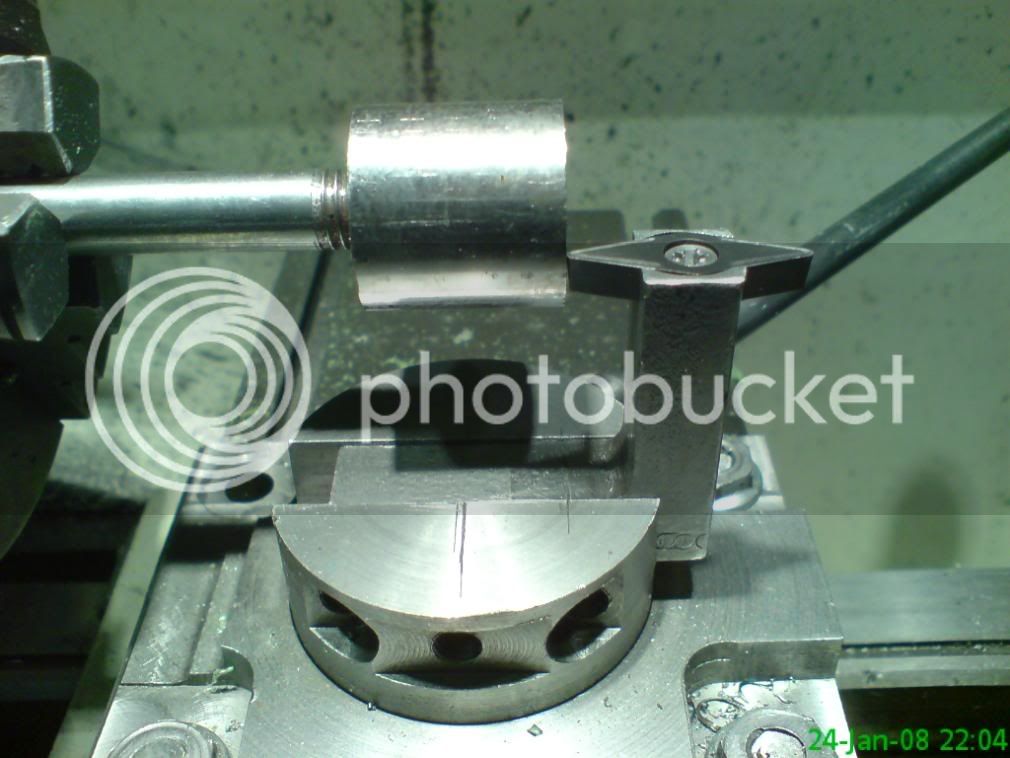

I not only have a ball turner... I built 3 different styles, basically because I was curious enough to want to see how each one performed. They are convenient for what they are and lots of fun to build and to use.

Having said that, I also use incremental cutting, freehand gravier, hand files, loads of sandpaper and now I'm beginning to adopt form tools. The point is that I use whatever works when the circumstances dictate it. I never wonder if it's what the pro's do and I don't worry if it's the "right" way. As long as everything stays well within the safety envelope, there are no barriers.

Heck.... I'll use just about anything that will get me to where I want to go. The family cat still hasn't forgiven me the day that I needed a small sable grade paint brush... even though the bare spots on his tail are long gone.

Keep sharing the techniques that work for you and I'll keep filing them away in my head until they are needed. That loud sucking sound, heard on the HMEM board, is made by us newbies absorbing all the great information this place makes available.

Thanks from all us newbies...

Steve

I not only have a ball turner... I built 3 different styles, basically because I was curious enough to want to see how each one performed. They are convenient for what they are and lots of fun to build and to use.

Having said that, I also use incremental cutting, freehand gravier, hand files, loads of sandpaper and now I'm beginning to adopt form tools. The point is that I use whatever works when the circumstances dictate it. I never wonder if it's what the pro's do and I don't worry if it's the "right" way. As long as everything stays well within the safety envelope, there are no barriers.

Heck.... I'll use just about anything that will get me to where I want to go. The family cat still hasn't forgiven me the day that I needed a small sable grade paint brush... even though the bare spots on his tail are long gone.

Keep sharing the techniques that work for you and I'll keep filing them away in my head until they are needed. That loud sucking sound, heard on the HMEM board, is made by us newbies absorbing all the great information this place makes available.

Thanks from all us newbies...

Steve