Blimey Jim if that one sold for £800 including the DRO someone sure got a bargain :

............ the new price of mill + Newall DRO is I believe well over £2.5k and that's without any tooling ................ Oh well, as you say, if that's the case ..............

Rob, Cheers

............ third time lucky, hopefully

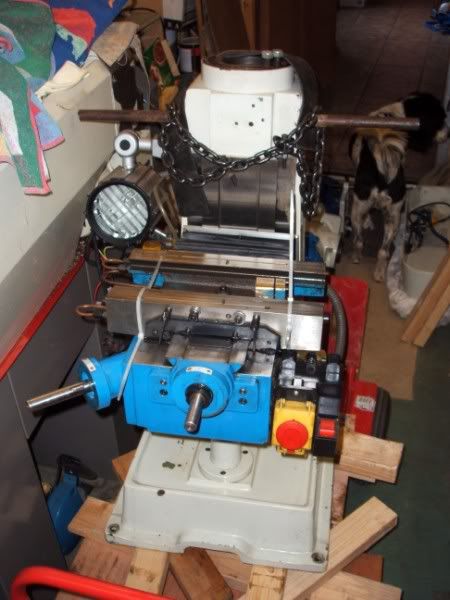

anyway ............. a better evening, after a busy, and very physical day at work (for which I'm getting far too old ;D ) .......... my lifting appliance's arrived ..............

and shortly thereafter .....................

Handy having large son's ;D

Anyway, everything fits together, it spins over fine, the power feed works .......... very well .......... even the light works and the "one shot" lubrication squirts oil somewhere ................ which very shortly ends up in the coolant tray :big:

:big:

at just before midnight, I felt it best not to spin it up and make a few chips, though I was sorely tempted ??? ............... Oh well, Thursday perhaps ........... I'll keep you posted

CC