- Joined

- May 18, 2010

- Messages

- 84

- Reaction score

- 10

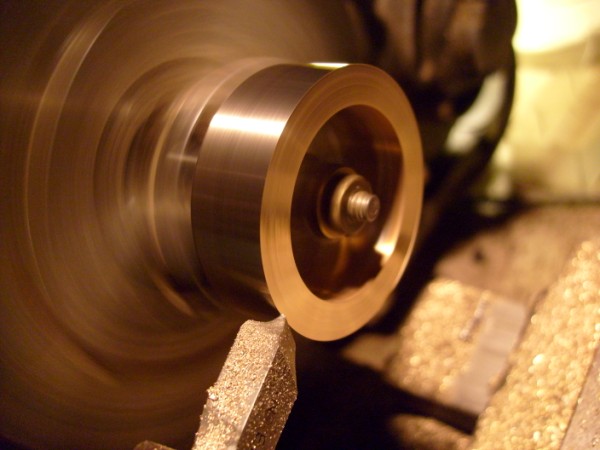

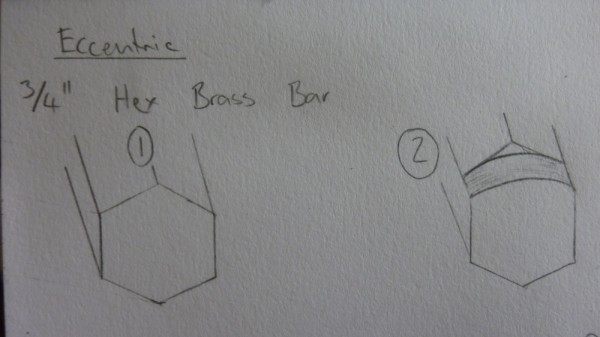

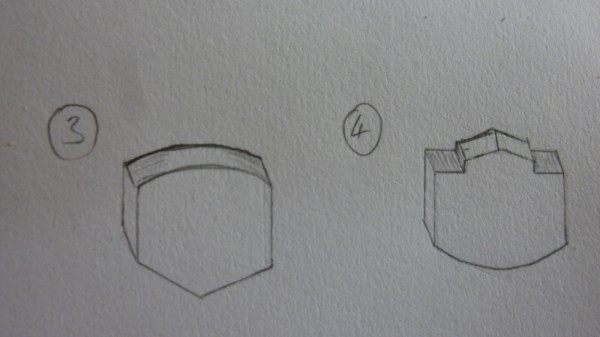

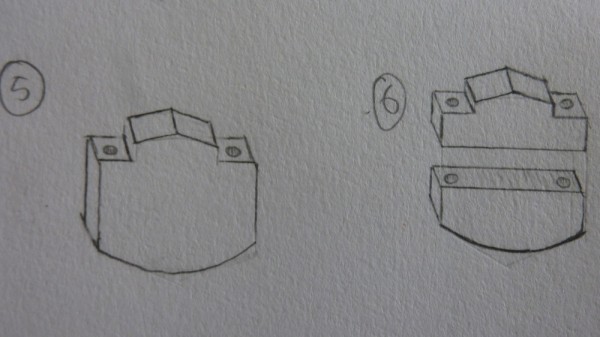

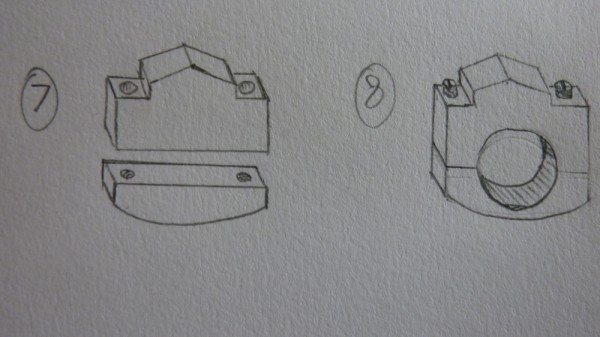

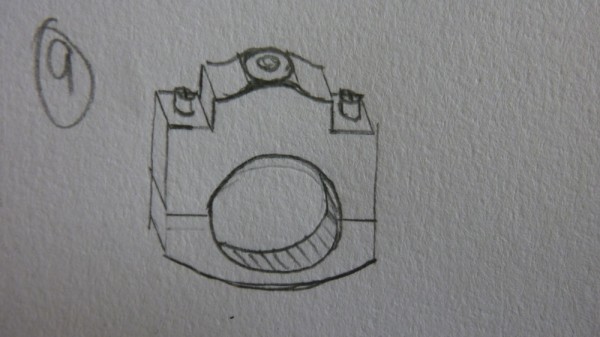

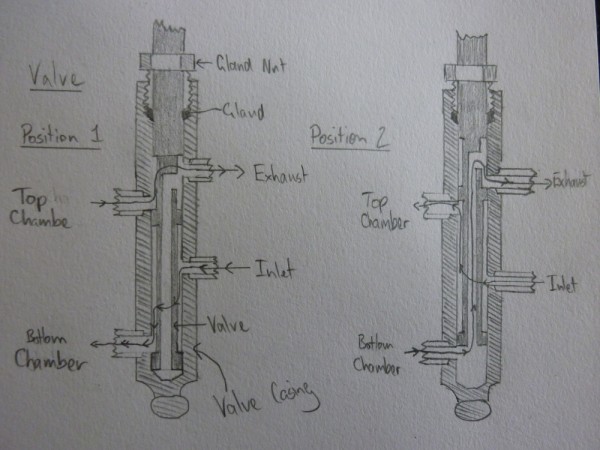

Here are a couple of pictures of the 6th engine I've built. It's a double acting 'upside-down' engine. My favorite part is the eccentric. There were no castings used in the making of the engine, not because I didn't want to use them, but because I haven't managed to get a foundry together yet - soon hopefully. It runs very well and I'm quite happy with it.

http://www.youtube.com/v/CmPlokiBrYE&hl=en_US&fs=1&

My other engines can be seen on my site www.peake-engines.com (among them is a super tiny oscillating engine which is for sale - it's less than an inch tall)

Thanks for looking,

Ben Peake

http://www.youtube.com/v/CmPlokiBrYE&hl=en_US&fs=1&

My other engines can be seen on my site www.peake-engines.com (among them is a super tiny oscillating engine which is for sale - it's less than an inch tall)

Thanks for looking,

Ben Peake