Tony Bird

Senior Member

Hi,

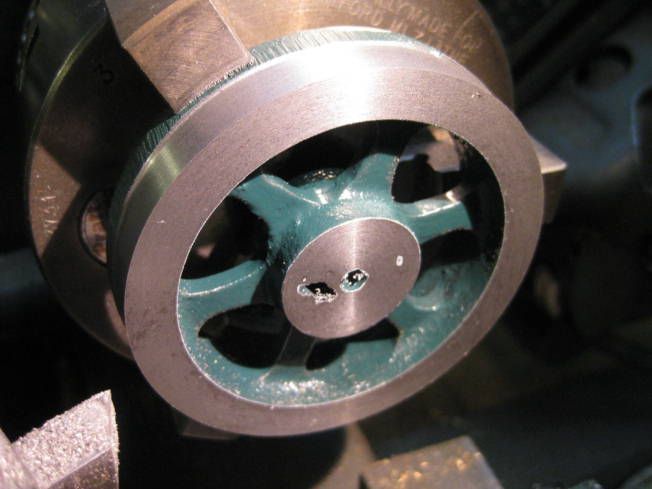

I usually keep a 3" to 4" flywheel in stock as it is usually a suitable size for most of the engines that I design and build. Having used my last flywheel on a model, recently at a ME exhibition I bought a replacement casting. Unfortunately the only suitable flywheel casting I could find at the exhibition was flawed, there were blow holes in its centre boss. The seller only wanted a £1 for it so it wasn't much of a gamble. After cleaning up and a coat of paint it was machined. The following photographs show the result.

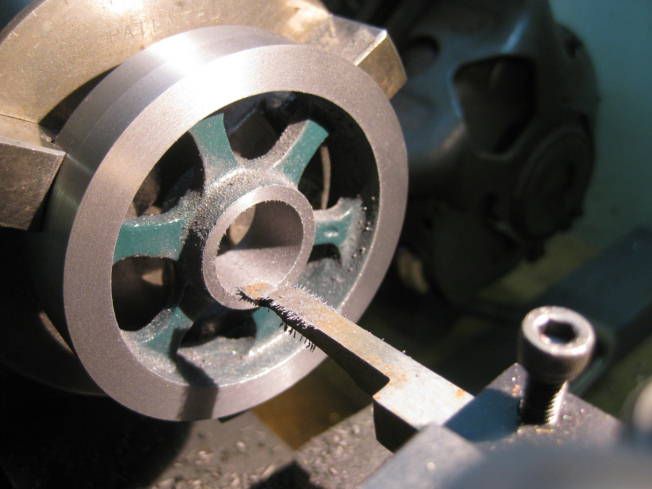

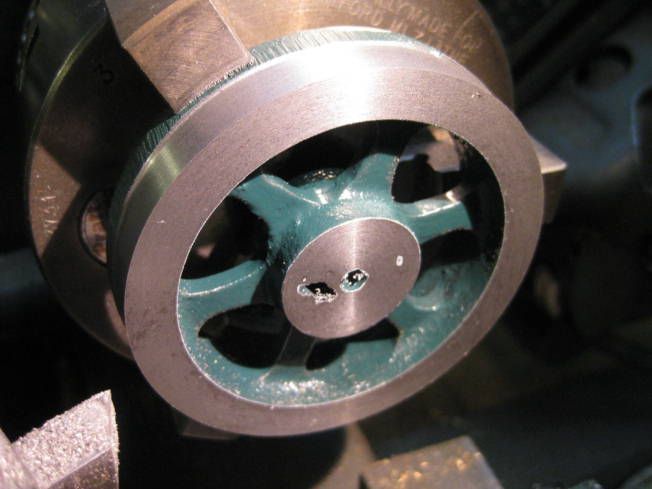

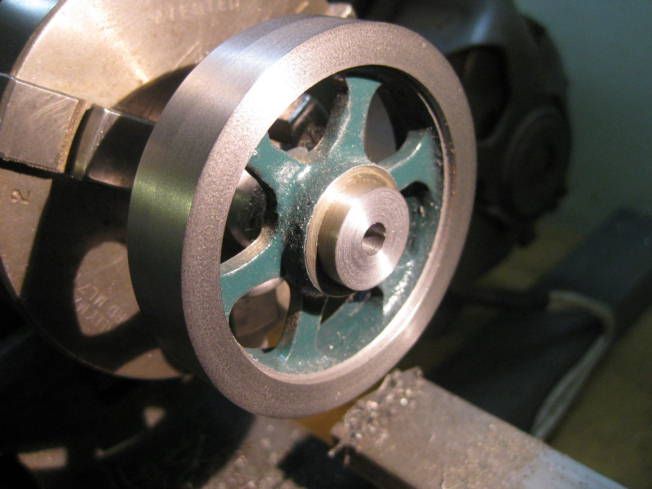

The casting was then centre drilled followed by a large drill before boring.

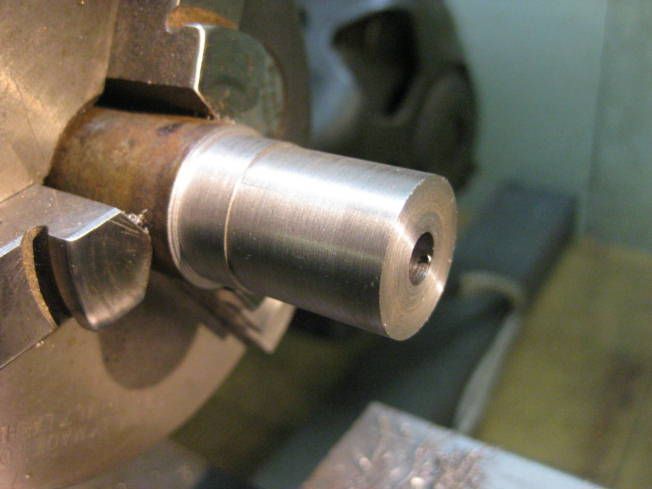

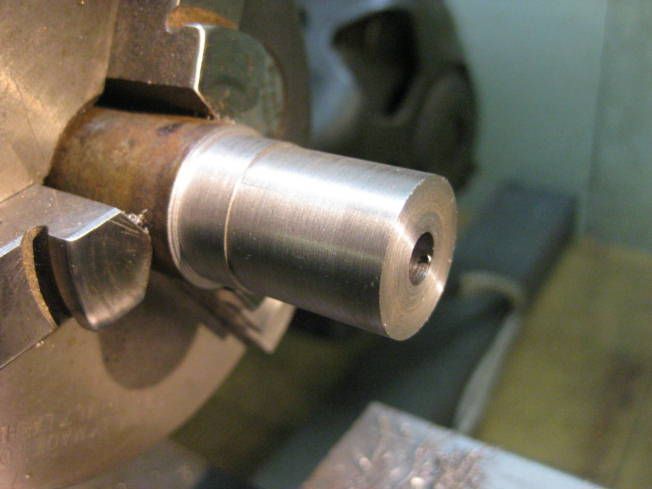

A new boss was turned.

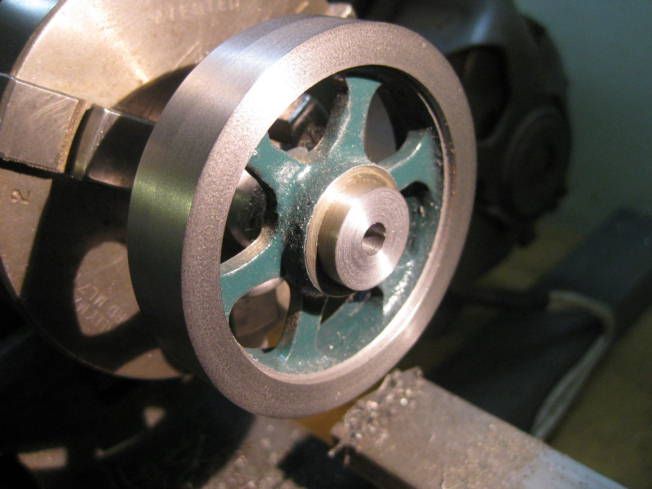

And the flywheel attached using Loctite.

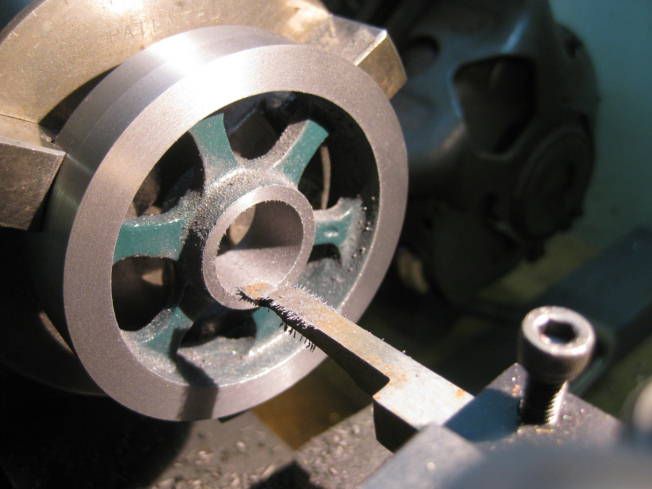

Boss drilled for screw.

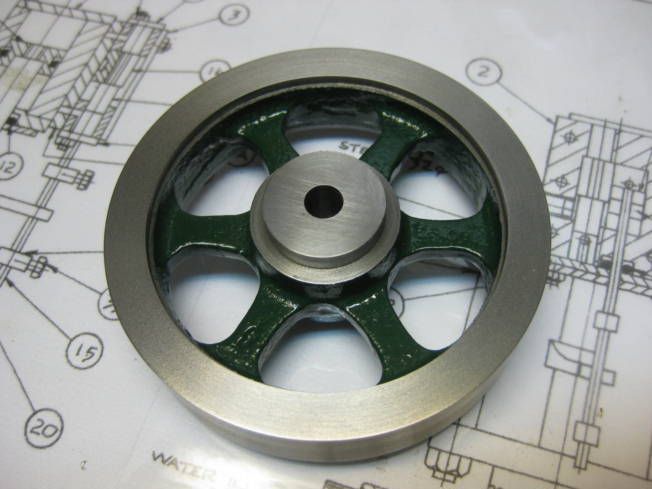

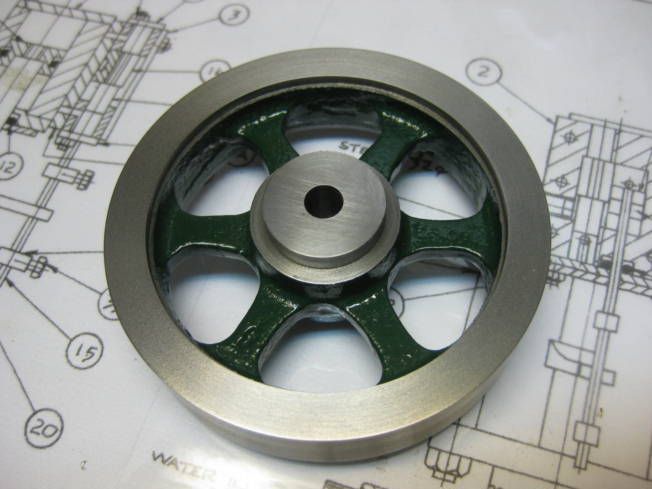

Finished flywheel.

I wouldn't normally machine a casting until I had a use for it but as it was defective I needed to know if it was OK. Certainly the quality of the cast iron was very good.

Regards Tony.

I usually keep a 3" to 4" flywheel in stock as it is usually a suitable size for most of the engines that I design and build. Having used my last flywheel on a model, recently at a ME exhibition I bought a replacement casting. Unfortunately the only suitable flywheel casting I could find at the exhibition was flawed, there were blow holes in its centre boss. The seller only wanted a £1 for it so it wasn't much of a gamble. After cleaning up and a coat of paint it was machined. The following photographs show the result.

The casting was then centre drilled followed by a large drill before boring.

A new boss was turned.

And the flywheel attached using Loctite.

Boss drilled for screw.

Finished flywheel.

I wouldn't normally machine a casting until I had a use for it but as it was defective I needed to know if it was OK. Certainly the quality of the cast iron was very good.

Regards Tony.