- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

About a year ago I had the opportunity to acquire a very nice asian copy of a Hardinge 11x19 tool room lathe. Besides my son needed a lathe so my very nice 10 x 30 engine lathe went to his house. Love the new lathe, BUT it was built with John Wayne in mind. Since I am 5'6" (almost) and the new lathe was about 4 inches taller than my old lathe I could not see over the tool post. For larger parts there was no problem, but for small parts close to a collet I could not see the part or tool tip. Standing on tip toes almost made it but even then I could not see very well and it was a bit tiring.

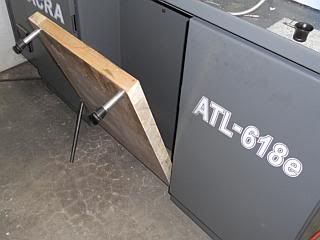

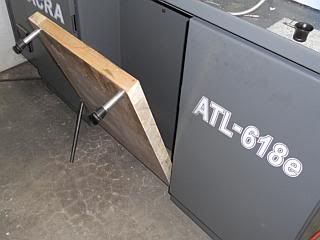

There is a nice foot/knee space on the lathe, so a section of old solid core door was cut to fit. A couple of lag bolt with a matching pair of bushings hinged the platform into the space. Two legs were made of 5/8 stock and rubber cane tips put on them. In the well a pair of rubber stick on feet we placed so the platform had a cushion to rest on when in the stored position.

Raises me almost 5 inches.

Easy to fold down when needed and up out of the way when not.

In the first and second photos there is an obvious safety rule violation. Can you spot what it is? Answer follows the photos.

A jewelers loupe is sitting with the eyepiece part facing up. When ever a loupe is not in use the lens should be facing up so chips and other dirt can settle inside. Nothing like dumping a bunch of junk into your eye when you go to use it next. Also makes it easier to clean the lens as the outside part is what gets dirty and the inside stays clean.

Gail in NM

There is a nice foot/knee space on the lathe, so a section of old solid core door was cut to fit. A couple of lag bolt with a matching pair of bushings hinged the platform into the space. Two legs were made of 5/8 stock and rubber cane tips put on them. In the well a pair of rubber stick on feet we placed so the platform had a cushion to rest on when in the stored position.

Raises me almost 5 inches.

Easy to fold down when needed and up out of the way when not.

In the first and second photos there is an obvious safety rule violation. Can you spot what it is? Answer follows the photos.

A jewelers loupe is sitting with the eyepiece part facing up. When ever a loupe is not in use the lens should be facing up so chips and other dirt can settle inside. Nothing like dumping a bunch of junk into your eye when you go to use it next. Also makes it easier to clean the lens as the outside part is what gets dirty and the inside stays clean.

Gail in NM