Holt

Well-Known Member

- Joined

- Oct 14, 2010

- Messages

- 164

- Reaction score

- 4

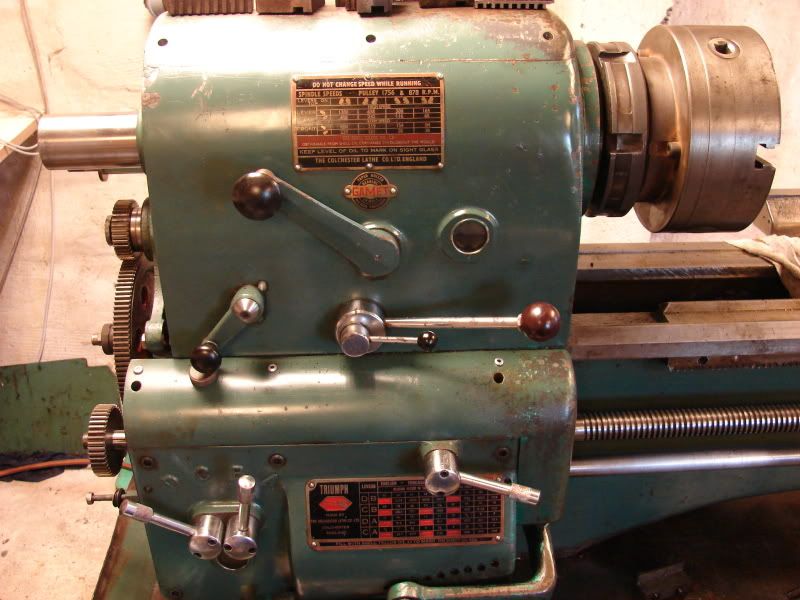

We tried, but we couldn't have them on the trailer ;DCMS said:Nice lathe score, but I think that I like the big MF's in the background just as much. Craig

I got another bargain the other night, a heidenhain interpolation box on eBay Germany, winning bit 12,50 EUR or about 16 USD