- Joined

- Jan 3, 2008

- Messages

- 2,085

- Reaction score

- 17

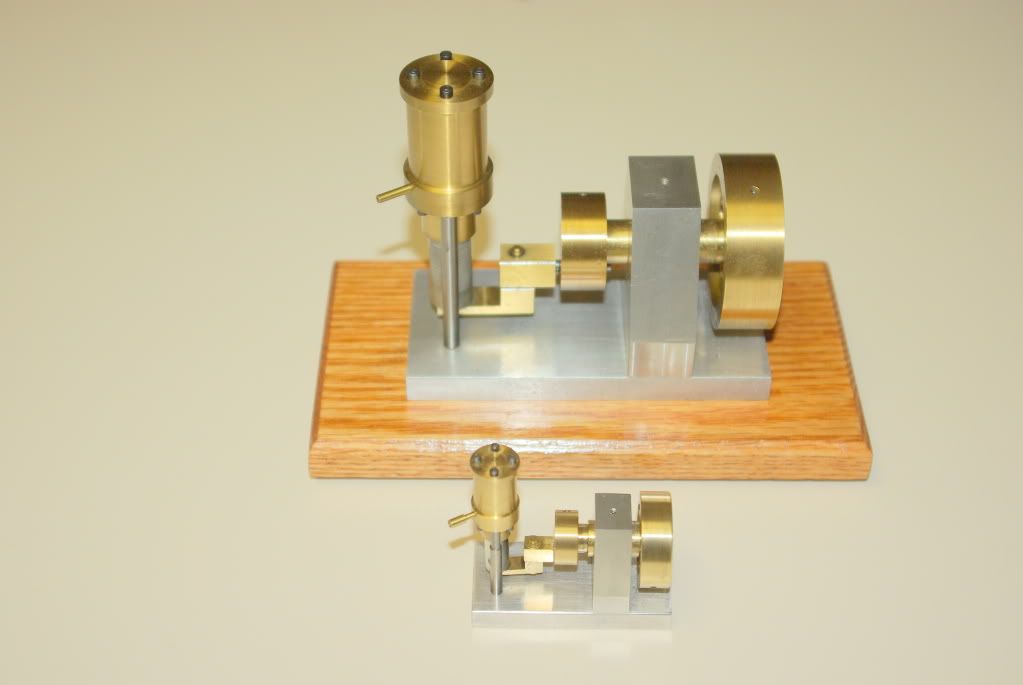

I had previously posted what I called an Oscillating Piston Valve engine. Though it runs well I always thought it was a bit large so I have been working on a half scale version, albeit with slow progress. Everything but the piston and linkage is now complete and I hope to have it running over the weekend if all goes well. A picture for size comparison with the original is shown below.