Twmaster

Well-Known Member

- Joined

- Oct 24, 2009

- Messages

- 917

- Reaction score

- 3

My other expensive hobby is flying R/C airplanes and crashing R/C helicopters.

As my vision is deteriorating I cannot see well enough to fly the smallish planes I've been flying for years. So now I am looking at bigger planes. Up until this I've flown nothing but electric powered craft for the last 10 years or so. Nitro-methane fuel is silly expensive at between $20 and $30 per gallon so that is out of the question for me. Flying larger electric planes is also very expensive.

So in steps the small 2 stroke power equipment engine....

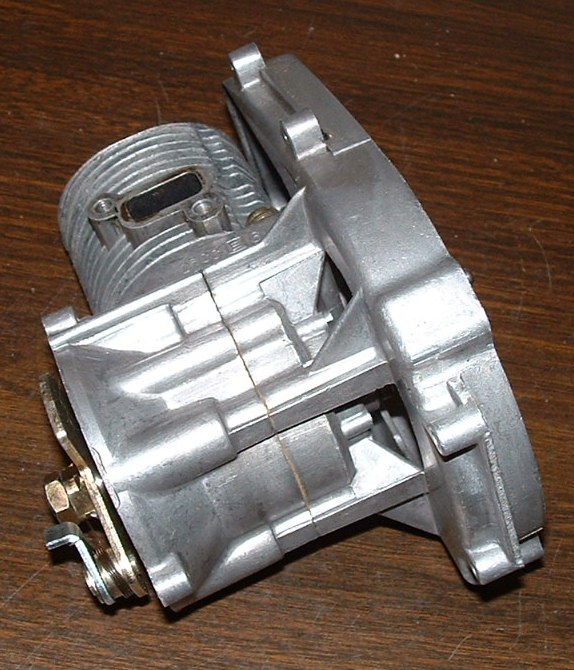

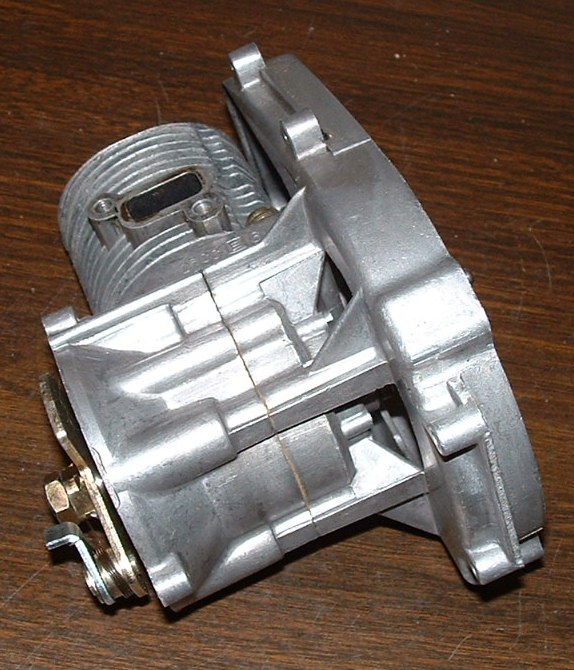

I bought two of these little Echo gas string trimmers. One runs, one has a bad bore/piston. I'm using the bad engine as the guinea pig.

First step is to get the engine relatively bare of the housings and such.

The following photos are the 'before' shots.

Weight as shown is just a hair over two pounds. I'll be doing away with the flywheel/magneto ignition and instead be using an electronic CDI type ignition.

This engine should be able to spin an 18 inch prop and fly a 9-10 pound sport airplane.

More pics of the work as it goes along. I hope to have a couple of posts per week until complete.

Thanks for looking!

As my vision is deteriorating I cannot see well enough to fly the smallish planes I've been flying for years. So now I am looking at bigger planes. Up until this I've flown nothing but electric powered craft for the last 10 years or so. Nitro-methane fuel is silly expensive at between $20 and $30 per gallon so that is out of the question for me. Flying larger electric planes is also very expensive.

So in steps the small 2 stroke power equipment engine....

I bought two of these little Echo gas string trimmers. One runs, one has a bad bore/piston. I'm using the bad engine as the guinea pig.

First step is to get the engine relatively bare of the housings and such.

The following photos are the 'before' shots.

Weight as shown is just a hair over two pounds. I'll be doing away with the flywheel/magneto ignition and instead be using an electronic CDI type ignition.

This engine should be able to spin an 18 inch prop and fly a 9-10 pound sport airplane.

More pics of the work as it goes along. I hope to have a couple of posts per week until complete.

Thanks for looking!