Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

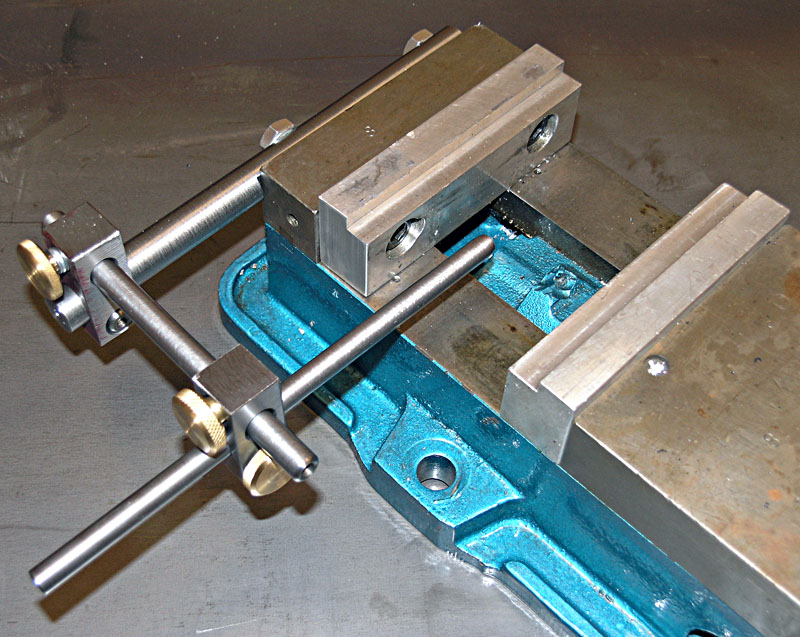

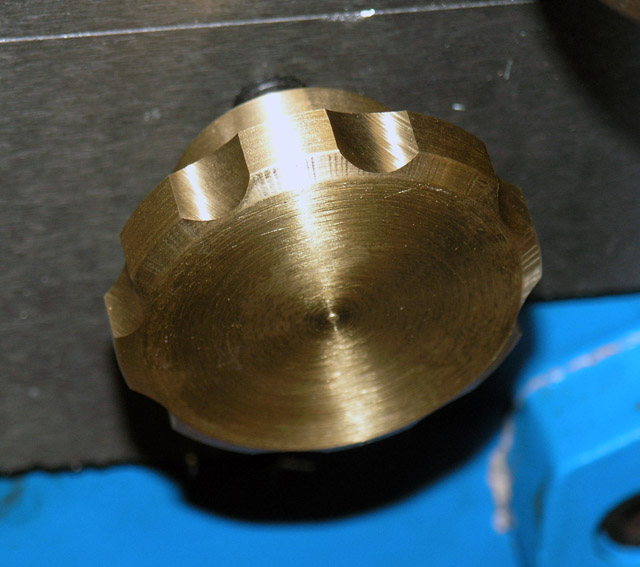

Decided to take a few minutes to build a vice stop for my little 2 inch vice. Used some scrap aluminum to make it. After I machined my pieces, I decided to powder coat them black. Just need to make some brass thumb screws.

Eric

Eric