Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

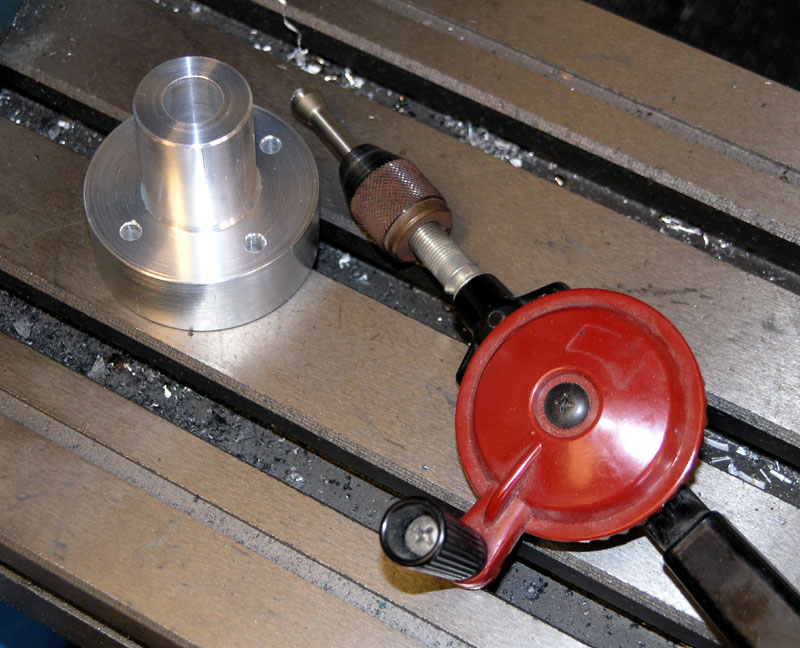

Here is a simple little tool that I use a "LOT". I deburr almost every single hole that I drill. This tool will do holes from about 1/32" up to about 7/16". Larger than that I use a different method. Usually a file or maybe large countersink in the drill press.

The first image shows the complete tool, and the second shows it dissembled, so you can see the construction. The handle has a metal sleeve epoxied inside.

Oh, I need to mention, in order to use it you have to teach your hand to Hula Hula.

Birk

The first image shows the complete tool, and the second shows it dissembled, so you can see the construction. The handle has a metal sleeve epoxied inside.

Oh, I need to mention, in order to use it you have to teach your hand to Hula Hula.

Birk