DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

Gents

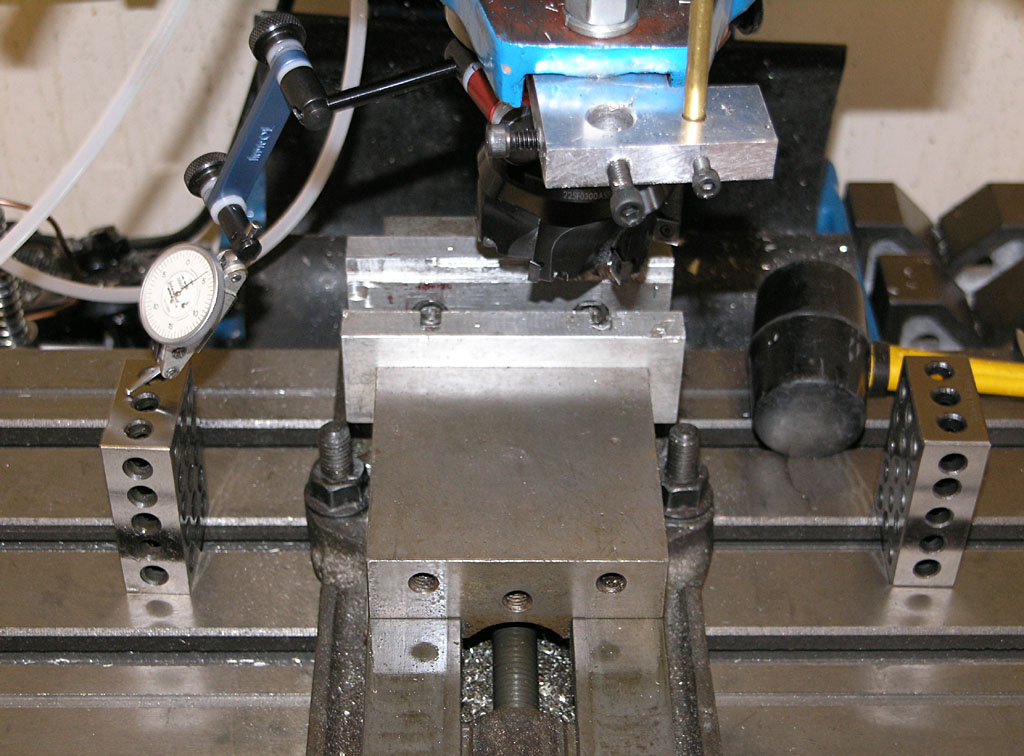

I hit upon this idea to check the tram of my mill without removing the vice and sweeping with a DTI. I don't know if it is my own thinking or I read about it elsewhere; anyway I'd appreciate you views on its accuracy. My mill head doesn't nod so I think it's a valid test.

I put the angle rod for my DTI into a collet at just past 90 degrees and measured the height to the highest point.

on the left and right. As it turned out, mine was spot on, but I guessed thet you could measure the high and low sides, then split the difference to adjust to correct it.

Sorry for the crap camera phone pics.

Al

I hit upon this idea to check the tram of my mill without removing the vice and sweeping with a DTI. I don't know if it is my own thinking or I read about it elsewhere; anyway I'd appreciate you views on its accuracy. My mill head doesn't nod so I think it's a valid test.

I put the angle rod for my DTI into a collet at just past 90 degrees and measured the height to the highest point.

on the left and right. As it turned out, mine was spot on, but I guessed thet you could measure the high and low sides, then split the difference to adjust to correct it.

Sorry for the crap camera phone pics.

Al