Hi Guys,

I take no credit for this device. I found it on another site. Not sure whether any pf u have seen it but worth posting. Designed by John Stevenson of England.

Method of use.

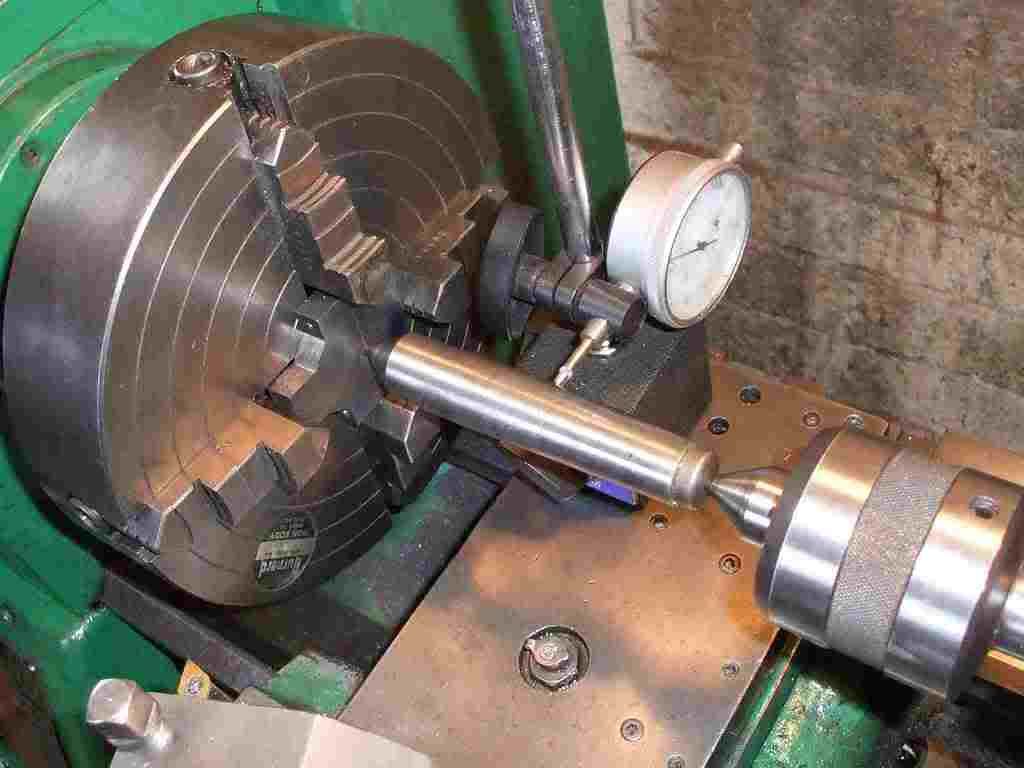

Always adjust using the opposite jaws at all times ie treat as two 2j chucks. Adjust by eye as near as possible then use the above. Two chuck keys are better than one. Check one set and then turn 180deg. Adjust untill as little change as possible between the 180deg positions. Do the other set of jaws in same way then recheck both sets. Looks a very useful piece of kit so building one now as it is not machine specific.

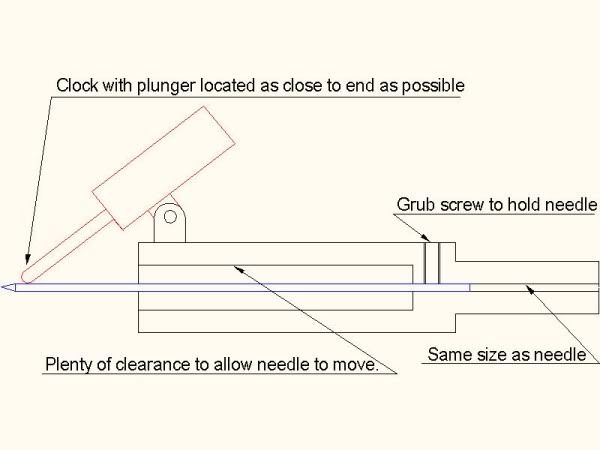

Tip from John Stevensons text is....adjust the needle so it is as close to the point of the DI as possible.

Julian

in probably-gonna-rain-Leicester

I take no credit for this device. I found it on another site. Not sure whether any pf u have seen it but worth posting. Designed by John Stevenson of England.

Method of use.

Always adjust using the opposite jaws at all times ie treat as two 2j chucks. Adjust by eye as near as possible then use the above. Two chuck keys are better than one. Check one set and then turn 180deg. Adjust untill as little change as possible between the 180deg positions. Do the other set of jaws in same way then recheck both sets. Looks a very useful piece of kit so building one now as it is not machine specific.

Tip from John Stevensons text is....adjust the needle so it is as close to the point of the DI as possible.

Julian

in probably-gonna-rain-Leicester