Tony Bird

Senior Member

Hi,

About thirty years ago I built a Dore Westbury milling machining from part machined castings. It has given excellent service since its only problem is the design of the 'T' slots on its table, not having any full length longitudinal slots, clamps often had to be used to hold a lot of machine vices, rotary tables etc. that were fitted to the table Recently a member of my model club who looks after its workshop bought a similar second hand mill, he couldn't put up with the inconvenience of not being able to just bolt things to the table. He connected the two short longitudinal 'T' to make one. Following photographs show the operation.

Mill as original.

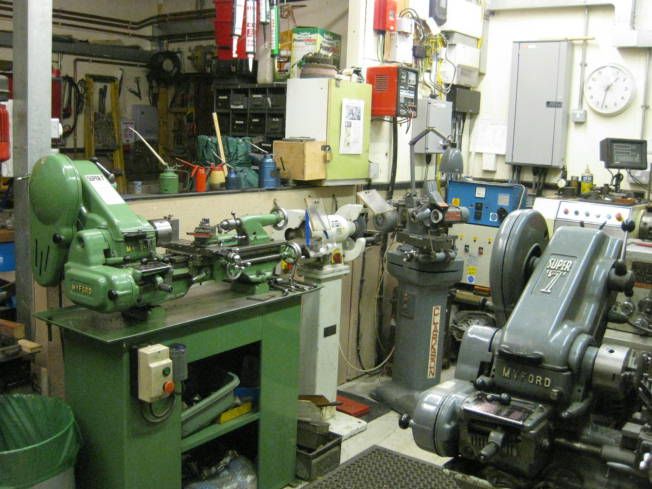

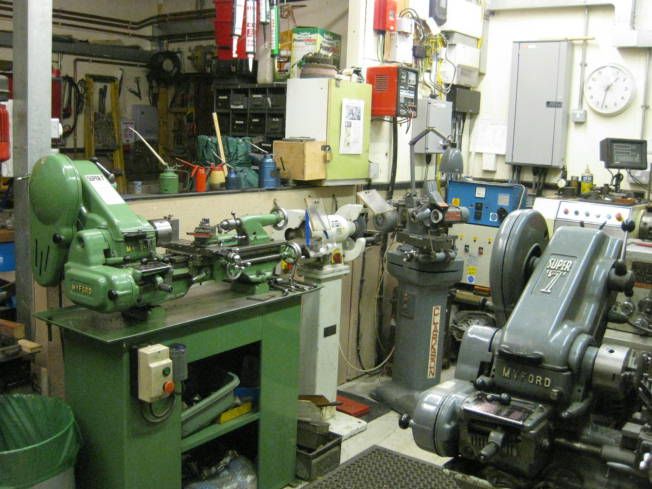

Model club workshop.

Eddie's weapon of choice the Baron Max.

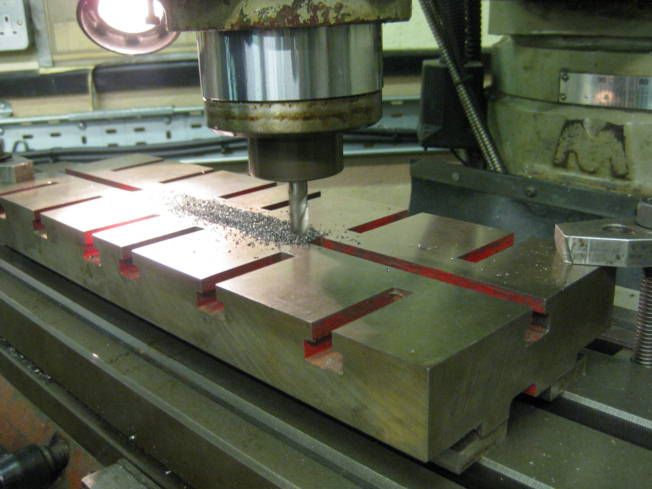

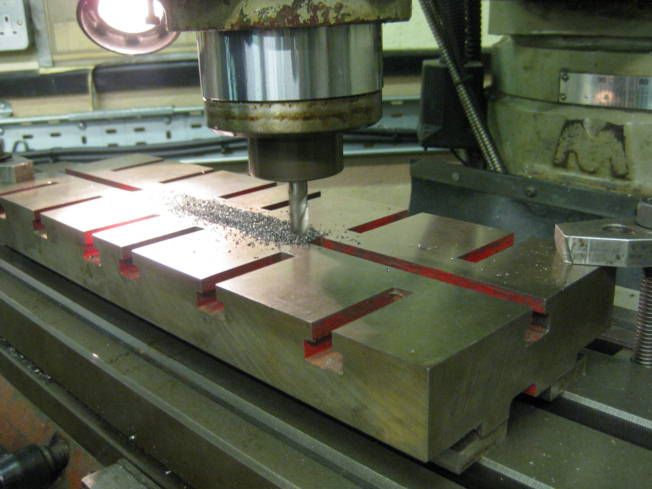

First Cut.

Eddie checking depth.

Last end mill cut.

'T milling cutter.

Photobucket seems to me playing up so I will close and continue on a another post.

Regards Tony.

About thirty years ago I built a Dore Westbury milling machining from part machined castings. It has given excellent service since its only problem is the design of the 'T' slots on its table, not having any full length longitudinal slots, clamps often had to be used to hold a lot of machine vices, rotary tables etc. that were fitted to the table Recently a member of my model club who looks after its workshop bought a similar second hand mill, he couldn't put up with the inconvenience of not being able to just bolt things to the table. He connected the two short longitudinal 'T' to make one. Following photographs show the operation.

Mill as original.

Model club workshop.

Eddie's weapon of choice the Baron Max.

First Cut.

Eddie checking depth.

Last end mill cut.

'T milling cutter.

Photobucket seems to me playing up so I will close and continue on a another post.

Regards Tony.