DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

Gents,

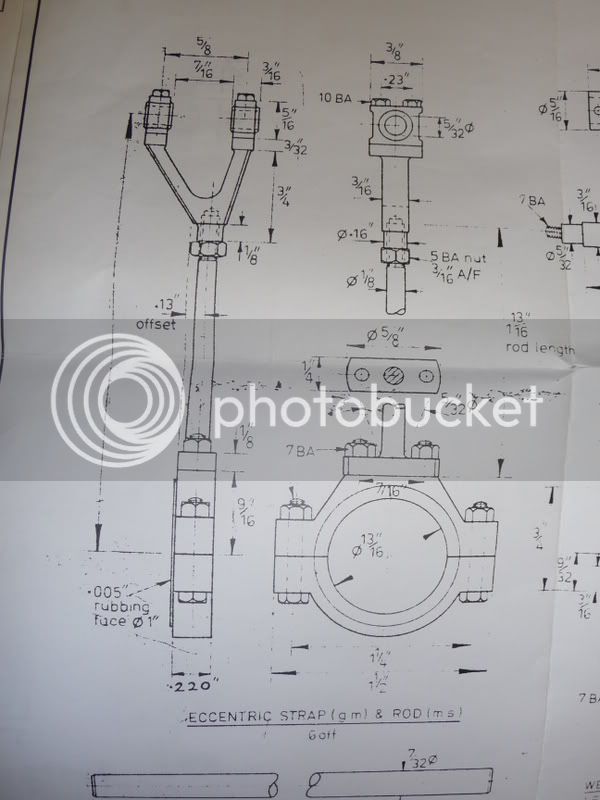

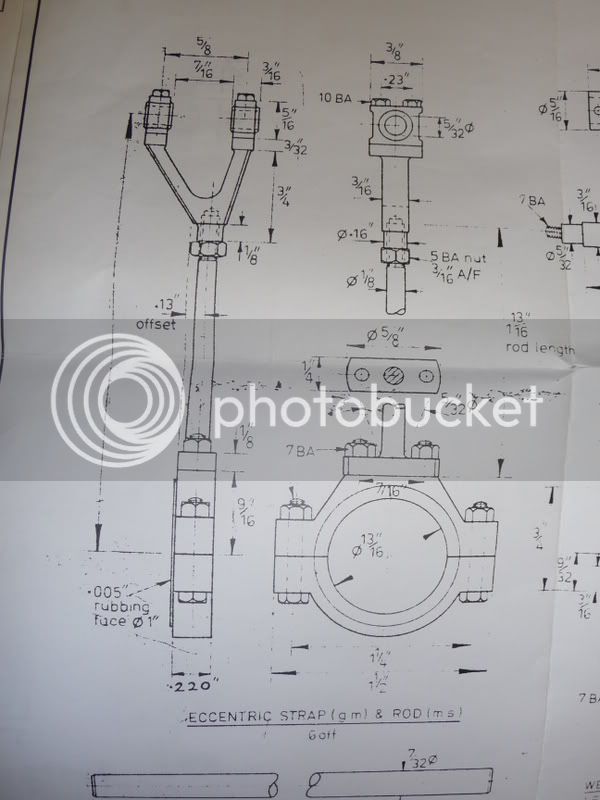

I'm in the middle of making the straps at present and I don't think the yokes will present a problem but a further gander at the drawing threw up an anomoly to me:

How do you read the offset on the mild steel rod? 0.13"

Off centre along length?

0.13" off centre at the far end ie skewed?

How would you make them? I need 6.

I was gonna turn em from solid and mill the flanges to make the flats.

TIA

Al

I'm in the middle of making the straps at present and I don't think the yokes will present a problem but a further gander at the drawing threw up an anomoly to me:

How do you read the offset on the mild steel rod? 0.13"

Off centre along length?

0.13" off centre at the far end ie skewed?

How would you make them? I need 6.

I was gonna turn em from solid and mill the flanges to make the flats.

TIA

Al