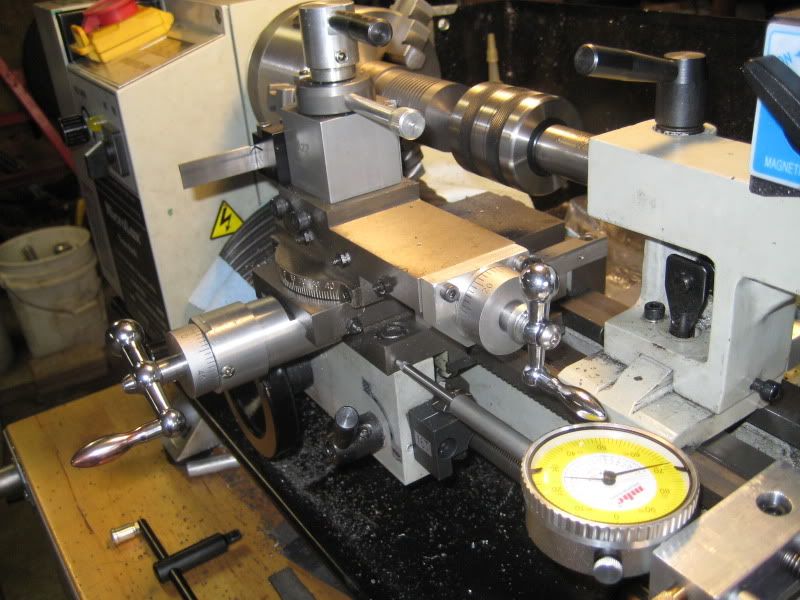

I have just purchased from LMS the A2Z CNC tool post for my 7x14 lathe. Now I have a question about this tool post. When mounted with the dove tails oriented one facing the chuck and the other facing parallel to the ways, the operating handle on mine points away from me towards the work between centers. The handle's arc is from the chuck to the tail stock over the work. This to me seems 180o in the wrong direction.

Do I drill and tap another hole on the opposite side for the handle?

Do I send the unit back because of faulty handle orientation?

Or is there something I'm missing in how this device works?

I know there are many users of this QCTP on mini lathes out there, and its hard for me to believe that mine is the only one with this problem. After all the cam that operates the clamping pistons and the handle boss are one piece and made by a CNC controlled machine!! So the location of the handle should be controlled by the program.

How does your example of this tool post sit on your lathe? What am I missing?

Do I drill and tap another hole on the opposite side for the handle?

Do I send the unit back because of faulty handle orientation?

Or is there something I'm missing in how this device works?

I know there are many users of this QCTP on mini lathes out there, and its hard for me to believe that mine is the only one with this problem. After all the cam that operates the clamping pistons and the handle boss are one piece and made by a CNC controlled machine!! So the location of the handle should be controlled by the program.

How does your example of this tool post sit on your lathe? What am I missing?