Ethan D

Well-Known Member

- Joined

- Nov 29, 2009

- Messages

- 51

- Reaction score

- 3

Hey Everyone,

I couldn't help myself, i had to post my project! Well the design stage of my project for now.

Currently i'm not in the position to start building it, because i'm getting married in 2 weeks, and saving for a house and lastly.... stuff to kit my future garage out with... SO.... i thought ill spend this time planning and designing the little Wankel.

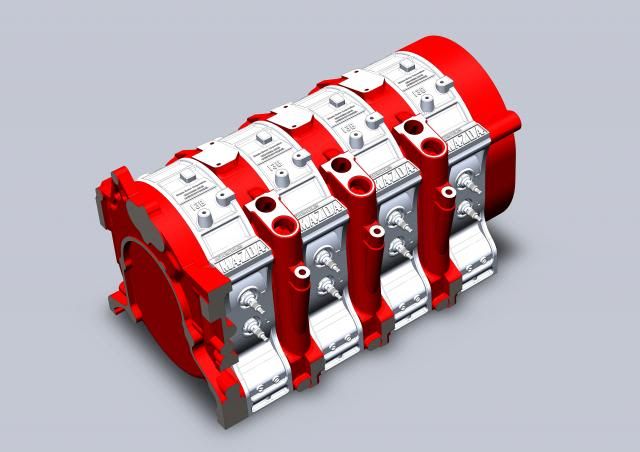

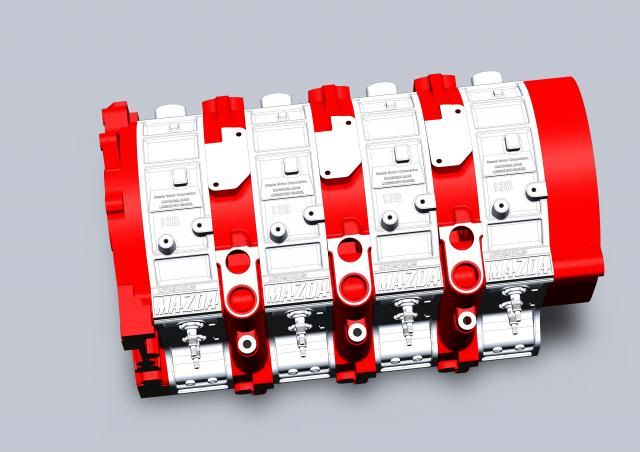

The little engine is being designed at 1/4 scale and based around a 13B from a RX4. Im planning to put as much detail as possible into this little motor to make it look just like its bigger brothers.

The motor will be approx 40cc, but that is still to be confirmed through calculations.

So far i have drawn up standard n/a housings (excluding exhaust ports), Center plate and currently drawing up the front plate. Below is a little description of whats been included in the current finished parts.

Housings:

They include all details of the copied 13B housing, I have included oil and water galleries, and cylinder chroming, excludes the exhaust port. Im still yet to decide whether ill cast the peripheral port into the housing, or modify the housings just like the guys do with the real ones.....

Center Plate:

Again all detail has been copied from the real center plate. I have included oil and water galleries.

The housings, center plates, front & rear plates and other covers will be casted using various methods. The parts will be very fine detail so I think ill get some parts of the molds 3D printed.

As this is my first engine, it might be a long and educational build. Feel free to comment and suggest ideas. I know its going to be a challenge but that's just the joy of this hobby

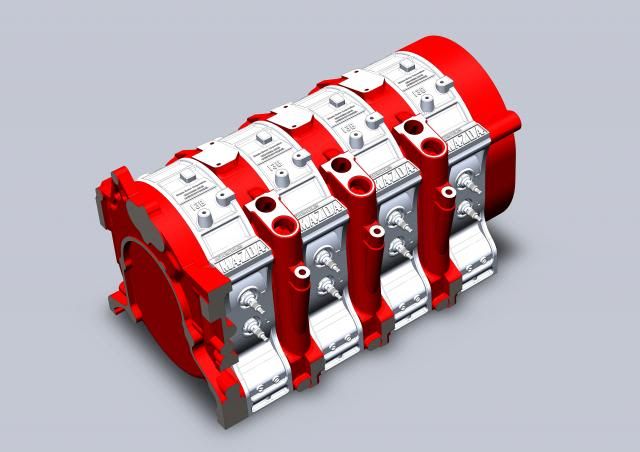

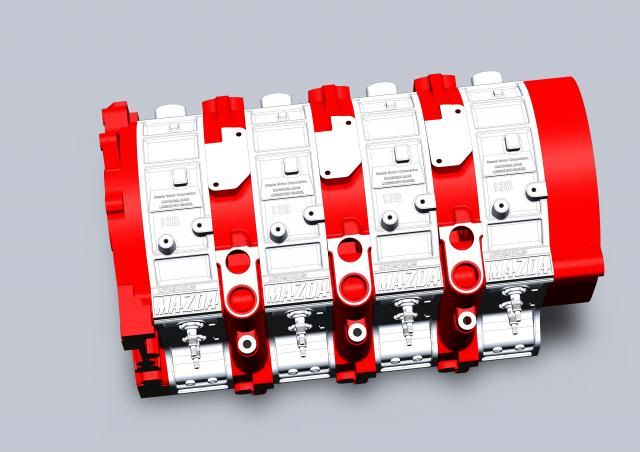

Here are some pictures of the model so far

Showing the inlet & exhaust side.

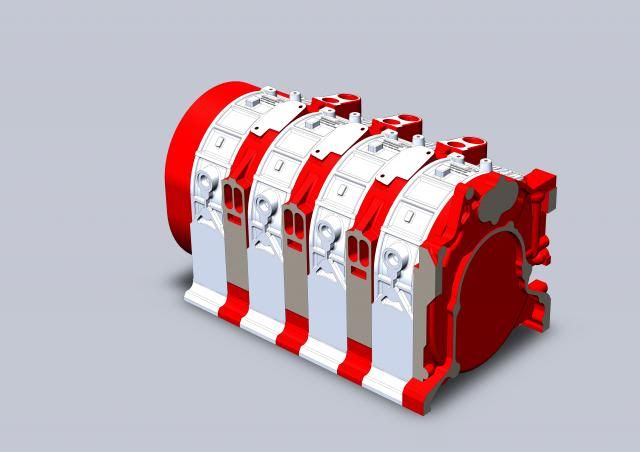

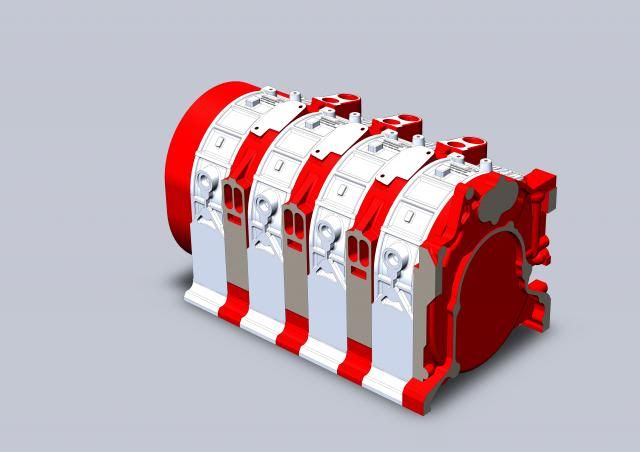

Section through housing.

Section through center plate.

More to come...

P.s... Sorry for the bad quality pictures. I dont have any detailed rendering with my software

Cheers

Ethan

I couldn't help myself, i had to post my project! Well the design stage of my project for now.

Currently i'm not in the position to start building it, because i'm getting married in 2 weeks, and saving for a house and lastly.... stuff to kit my future garage out with... SO.... i thought ill spend this time planning and designing the little Wankel.

The little engine is being designed at 1/4 scale and based around a 13B from a RX4. Im planning to put as much detail as possible into this little motor to make it look just like its bigger brothers.

The motor will be approx 40cc, but that is still to be confirmed through calculations.

So far i have drawn up standard n/a housings (excluding exhaust ports), Center plate and currently drawing up the front plate. Below is a little description of whats been included in the current finished parts.

Housings:

They include all details of the copied 13B housing, I have included oil and water galleries, and cylinder chroming, excludes the exhaust port. Im still yet to decide whether ill cast the peripheral port into the housing, or modify the housings just like the guys do with the real ones.....

Center Plate:

Again all detail has been copied from the real center plate. I have included oil and water galleries.

The housings, center plates, front & rear plates and other covers will be casted using various methods. The parts will be very fine detail so I think ill get some parts of the molds 3D printed.

As this is my first engine, it might be a long and educational build. Feel free to comment and suggest ideas. I know its going to be a challenge but that's just the joy of this hobby

Here are some pictures of the model so far

Showing the inlet & exhaust side.

Section through housing.

Section through center plate.

More to come...

P.s... Sorry for the bad quality pictures. I dont have any detailed rendering with my software

Cheers

Ethan