Barnbikes

Well-Known Member

- Joined

- Jul 19, 2014

- Messages

- 194

- Reaction score

- 41

Been around real size hit & miss engine most of my life and decided to build a model.

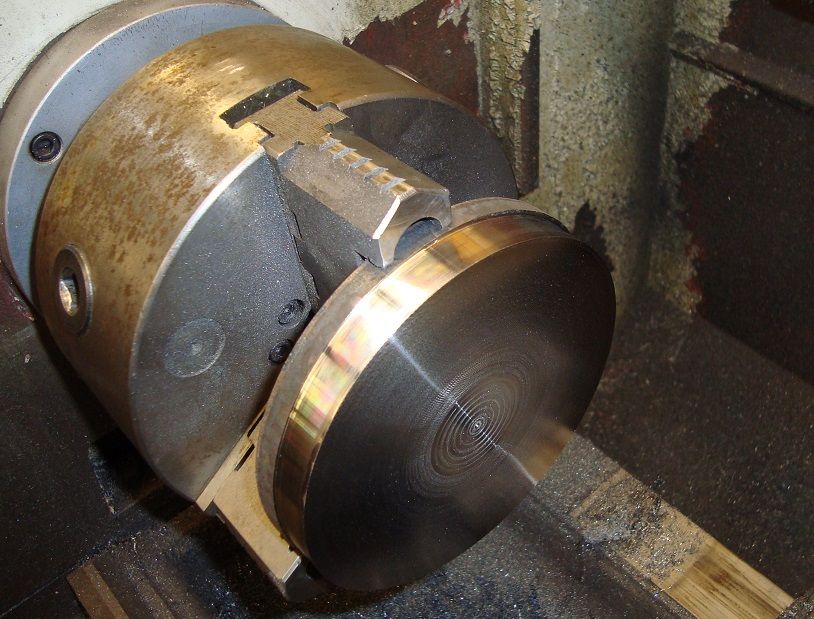

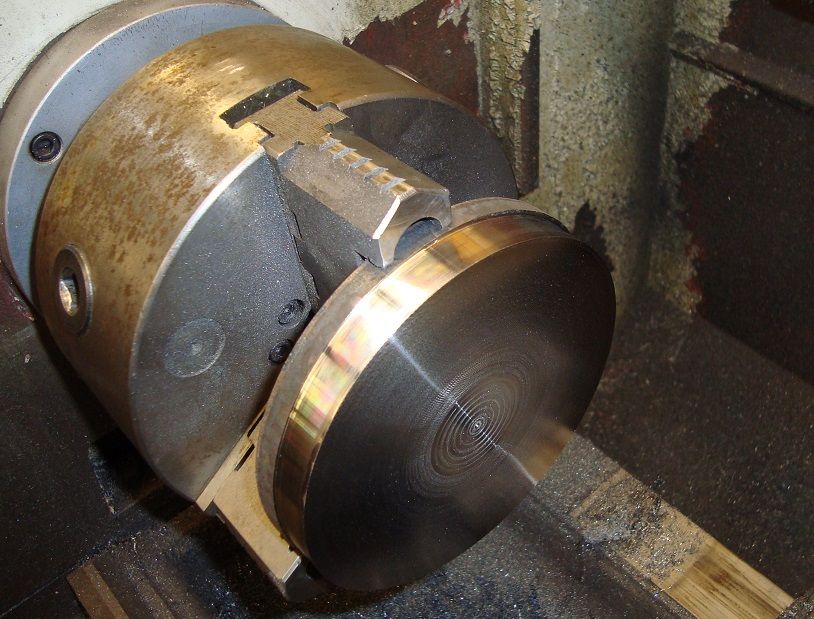

Picked up a laser cut 5"X1" slug drop for my flywheel and am turning it right now. Not sure if it is hardened by the laser or if it is tool steel but it sure is hard. Have 1.5 hours into right now and 3 tool tips and just have 1 side of it trued up.

Picked up a laser cut 5"X1" slug drop for my flywheel and am turning it right now. Not sure if it is hardened by the laser or if it is tool steel but it sure is hard. Have 1.5 hours into right now and 3 tool tips and just have 1 side of it trued up.