David Morrow

Well-Known Member

- Joined

- Sep 8, 2008

- Messages

- 227

- Reaction score

- 60

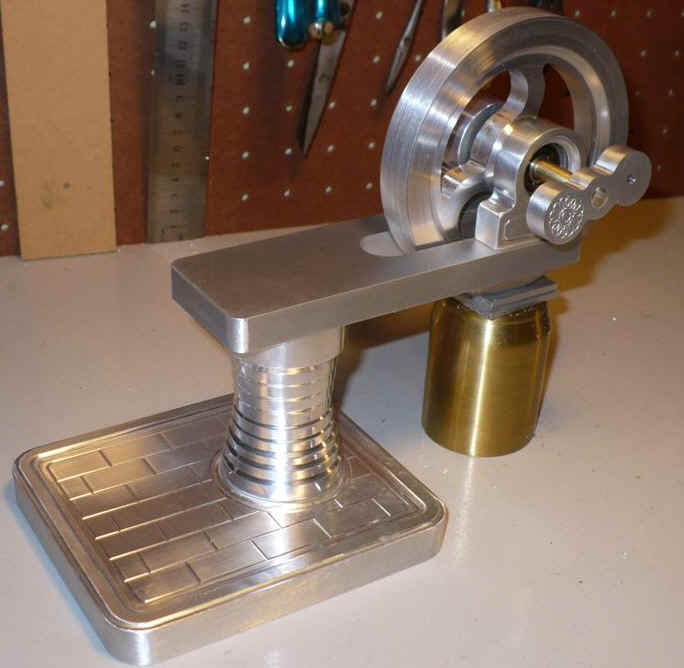

I'm mostly following the plans from HSM Nov/Dec 2005. I've sort of pimped it up a bit though. The column may be shortened a bit before it's done.

I've been playing with anodizing and have been quite happy with the quality and the ability to add some colour to my projects. I think this one will be a mix of black, red, and raw brushed aluminum.

Ignore the brass cylinder on the right - it's a part for another project and is just there to hold things up.

I've been playing with anodizing and have been quite happy with the quality and the ability to add some colour to my projects. I think this one will be a mix of black, red, and raw brushed aluminum.

Ignore the brass cylinder on the right - it's a part for another project and is just there to hold things up.