Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

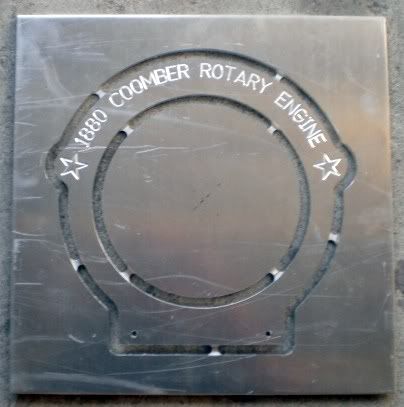

I've been wanting a bigger engine and this is it ) I have some of the pieces redrawn 3X their normal size in Mastercam. Today a few parts were welded up at work wrong

) I have some of the pieces redrawn 3X their normal size in Mastercam. Today a few parts were welded up at work wrong  so I was able to play on the CNC mill after words ;D ;D ;D I had the program and material ready a week ago. Here is what I turned out. I'm getting better at this CNC stuff, because I didn't have any problems.

so I was able to play on the CNC mill after words ;D ;D ;D I had the program and material ready a week ago. Here is what I turned out. I'm getting better at this CNC stuff, because I didn't have any problems.

The newer version of mastercam has a feature called tabs. When machining parts out of plate like this you can add these tabs and the parts wont fall out. They can easily be cut with dikes. I like it.

Wes

The newer version of mastercam has a feature called tabs. When machining parts out of plate like this you can add these tabs and the parts wont fall out. They can easily be cut with dikes. I like it.

Wes