russevertz

New Member

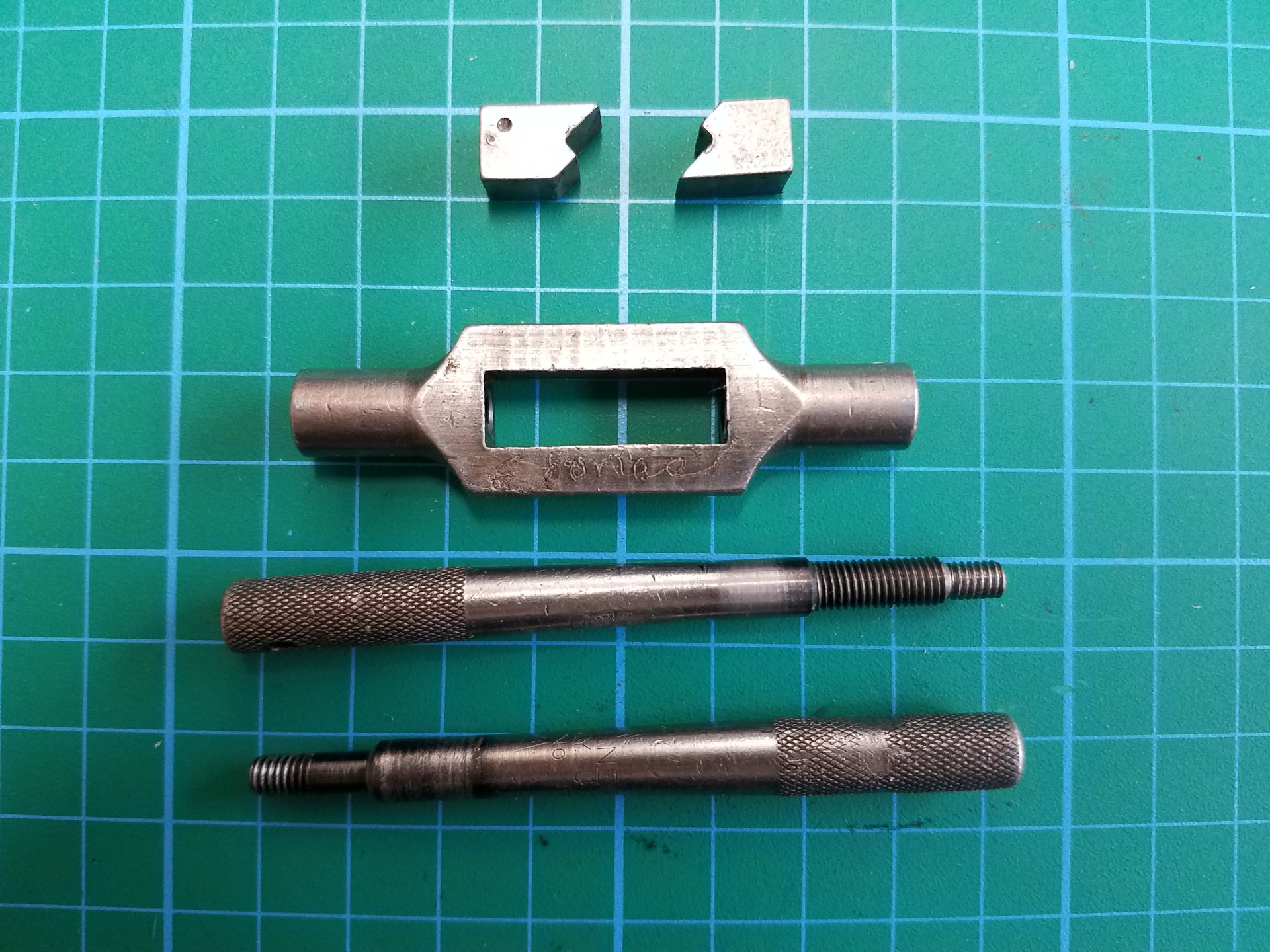

I have a Greenfield GTD Tap Handle No. 5 (also includes "5B"). It is currently missing the moving jaw. It has a reverse thread that threads into the handle.

Curious if anybody has one of these and can pull the moving jaw out and share the Thread pitch and Thread Diameter?

The fixed jaw comes out after releasing the set screw and then the moving jaw has enough travel to screw out of the handle.

I have been able to get a Drill Chuck retaining screw to thread in but it seems too loose. It is 6mm-1.1 pitch Left Hand Thread. This is close to 1/4-23.

Mr. Pete published the specs for the No 6 or 7 on a video and it was not a standard thread.

Hopefully someone on here has one and will help me out.

Thanks,

Russ

Greenfield GTD Tap Handle No. 5 5B Thread pitch and Diameter of Jaw

Curious if anybody has one of these and can pull the moving jaw out and share the Thread pitch and Thread Diameter?

The fixed jaw comes out after releasing the set screw and then the moving jaw has enough travel to screw out of the handle.

I have been able to get a Drill Chuck retaining screw to thread in but it seems too loose. It is 6mm-1.1 pitch Left Hand Thread. This is close to 1/4-23.

Mr. Pete published the specs for the No 6 or 7 on a video and it was not a standard thread.

Hopefully someone on here has one and will help me out.

Thanks,

Russ

Greenfield GTD Tap Handle No. 5 5B Thread pitch and Diameter of Jaw