digiex-chris

Well-Known Member

- Joined

- Dec 6, 2010

- Messages

- 263

- Reaction score

- 58

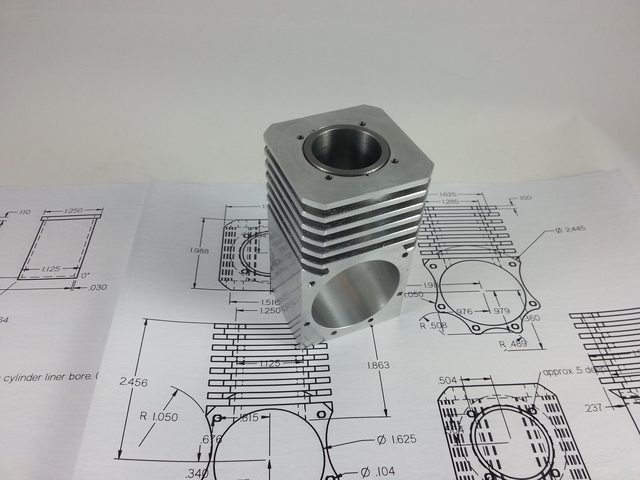

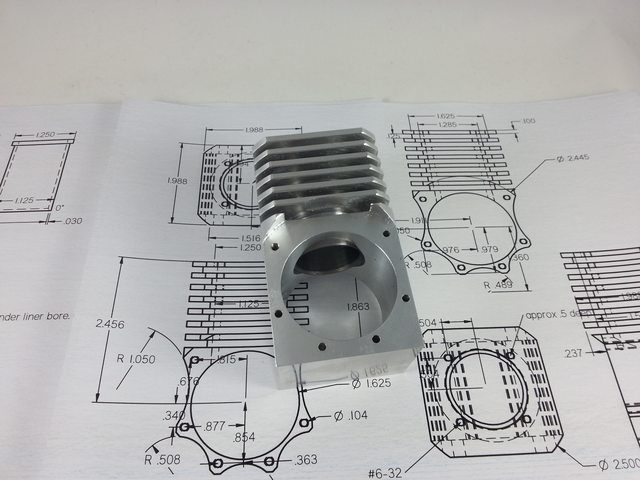

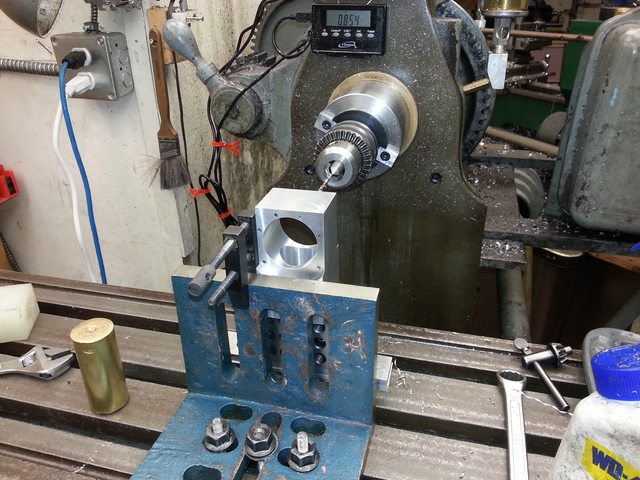

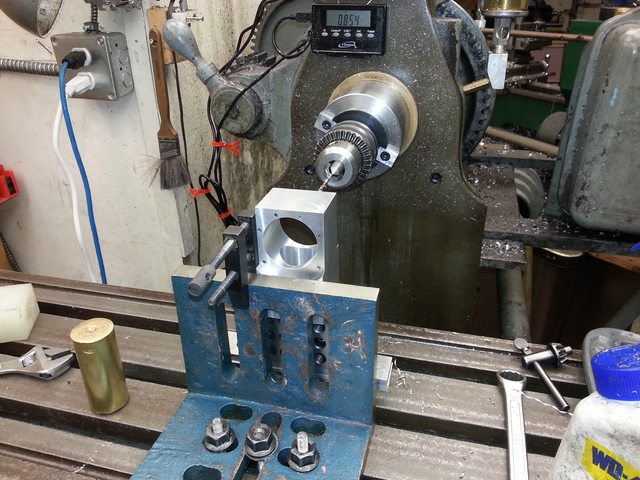

I wanted to install the cylinder liner into the block and turn the fins for something to do while I waited for my bearings to come in for the front cover. Since I didn't want to grab the relatively fragile fins in the vise, I decided to finish the lower end of the block now. Gus showed off using an angle plate, reminding me that I had one. Unfortunately because mine is cheese grade cast iron without a rib to stiffen it, I can push about 0.004" flex at the top of the 5" height. Oh well, it'll be fine for drilling a few bolt holes. Better than my drill press anyway, and better than trying to grab the bottom (top in this case) of a tall skinny object in my cheesy vise. No, that's not the only clamp I used, I'd just taken the clamps off and remembered to grab a picture. The toolmaker's clamp was used as a fence so I could flip the part around and get it close enough for the dial indicator to sweep the bore without much adjustment. On the front of the angle plate I'd stacked parallels and a 123 block so I wouldn't have to dial in the vertical face.

Back to the mandrel. Here's how I did it, after getting an example from a retired machinist family member. Make a 7 degree taper. Make a plug with a matching taper. Bore the start of the hole slightly larger than the thread major diameter, to allow a roll pin to fit in there. Cross drill your bolt for the pin. The pin then pulls the wedge out when you back the bolt out. The bolt head (actually a nut silver soldered onto fine thread rod, but same thing) needed to be turned down a bit, I underestimated how far in the plug would go before locking up on my cylinder. Warning: wobbly hack saw cut!

I put a slight amount of tension on the plug, then took a skim down to a perfect sliding fit on my cylinder liner. Then parted the back about half the depth to the counterbored roll pin clearance hole.

The ends are cleaned up

And 0.003" oversize. I was getting tired so I decided to make the final shrink fit dimension the next day when I'd had more sleep and the correct amount of coffee. It'll give it a chance to equalize temperatures too. That 4140 got a little hot from the roughing passes.

Back to the mandrel. Here's how I did it, after getting an example from a retired machinist family member. Make a 7 degree taper. Make a plug with a matching taper. Bore the start of the hole slightly larger than the thread major diameter, to allow a roll pin to fit in there. Cross drill your bolt for the pin. The pin then pulls the wedge out when you back the bolt out. The bolt head (actually a nut silver soldered onto fine thread rod, but same thing) needed to be turned down a bit, I underestimated how far in the plug would go before locking up on my cylinder. Warning: wobbly hack saw cut!

I put a slight amount of tension on the plug, then took a skim down to a perfect sliding fit on my cylinder liner. Then parted the back about half the depth to the counterbored roll pin clearance hole.

The ends are cleaned up

And 0.003" oversize. I was getting tired so I decided to make the final shrink fit dimension the next day when I'd had more sleep and the correct amount of coffee. It'll give it a chance to equalize temperatures too. That 4140 got a little hot from the roughing passes.