Holt

Well-Known Member

- Joined

- Oct 14, 2010

- Messages

- 164

- Reaction score

- 4

Its been a while since my last thread, http://www.homemodelenginemachinist.com/f28/i-stole-lathe-16864/ and this is about the same lathe, I have been wanting DRO from the start, but have run into problems every time, I would of course prefer glass scales, but a 1.3 m glass scale for the main sattle is out of my league, I have seen some DRO sets using cheap Chinese digital calipers, which I think is precise enough for my use, the problem is the longest versions is 600 mm.

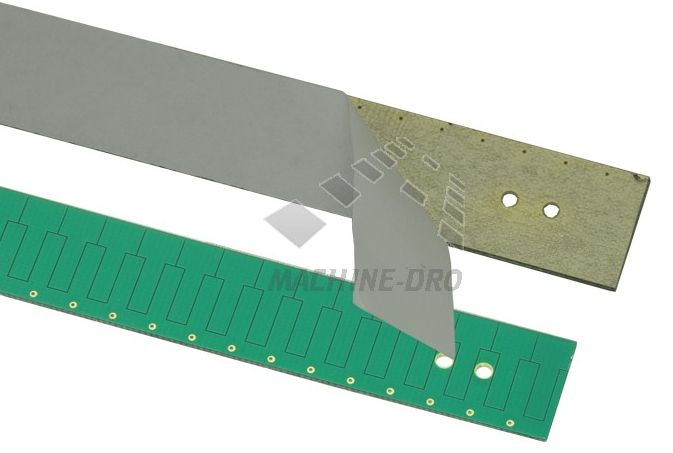

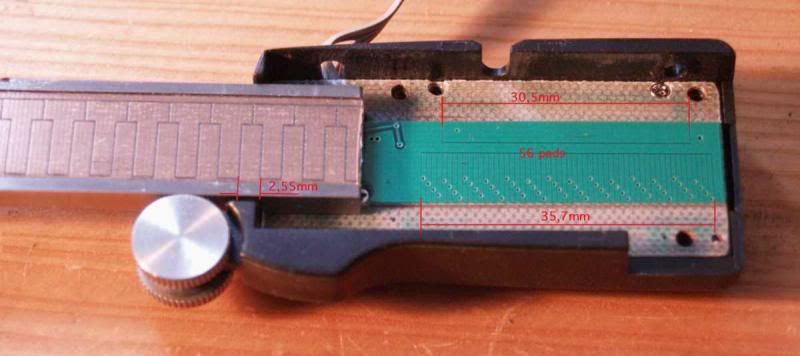

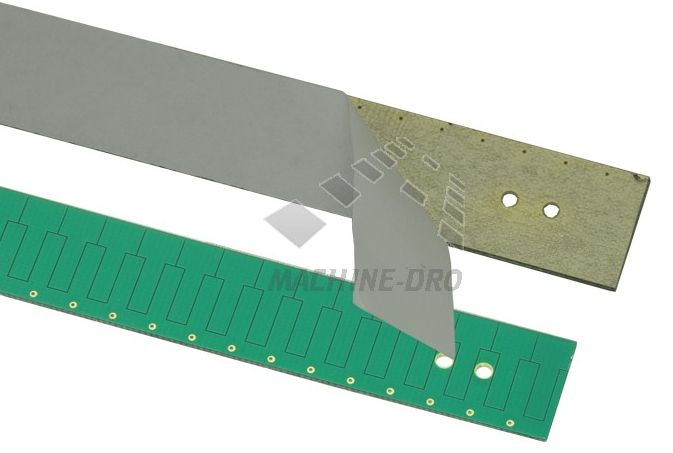

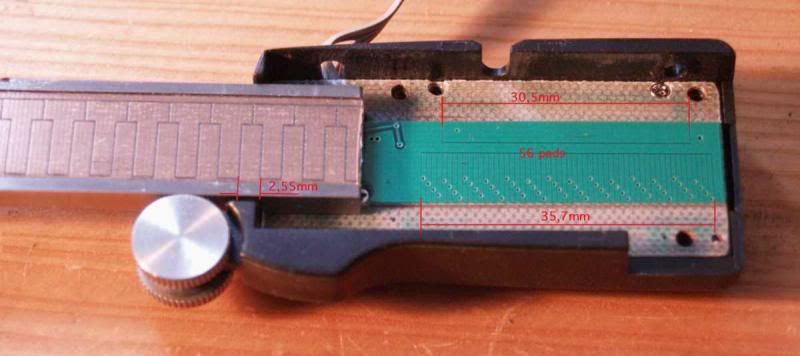

I then came across these replacement sensor strips for a Wixey saw.

They come in 800 mm lengths and two can be joined to 1600 mm length and have the exact same pattern as a digital caliper.

(photo from YADRO's home page)

I have read about people mounting these strips, but never heard if they worked satisfactory in the long term, anyone know about that?

If this is the way to go I would probably use them with this setup:

http://www.yuriystoys.com/p/android-dro.html

Holt

I then came across these replacement sensor strips for a Wixey saw.

They come in 800 mm lengths and two can be joined to 1600 mm length and have the exact same pattern as a digital caliper.

(photo from YADRO's home page)

I have read about people mounting these strips, but never heard if they worked satisfactory in the long term, anyone know about that?

If this is the way to go I would probably use them with this setup:

http://www.yuriystoys.com/p/android-dro.html

Holt

Last edited: