tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

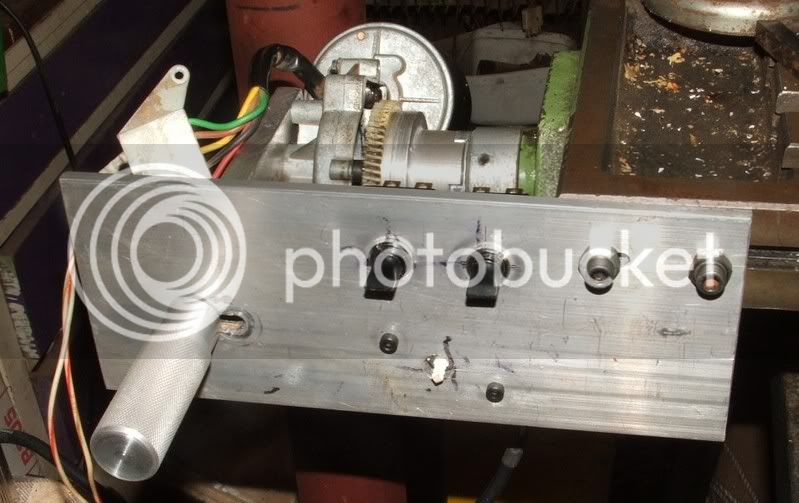

... another table drive springs to life - this time for the RF30. Not finished yet, but it is operating and is working out pretty good. Power plant is the usual windscreen wiper motor, driven, this time by a PC power supply.

The story so far.

1. Interface

2. With motor

3. The engaged position

4. Disengaged

The story so far.

1. Interface

2. With motor

3. The engaged position

4. Disengaged