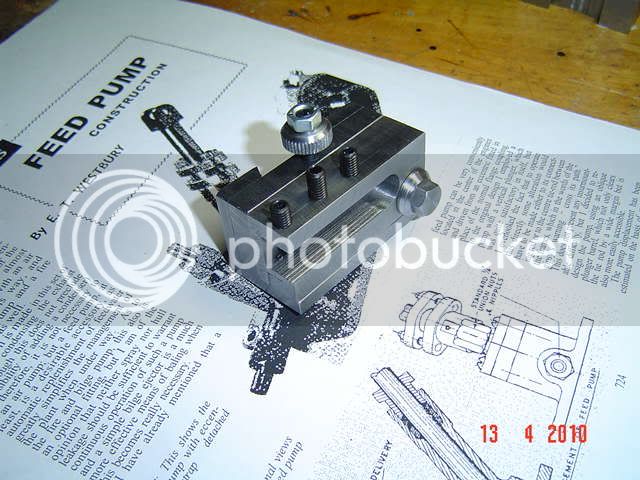

I needed another tool holding for my Tool post ...like this

but after few cutting...this is the results.... ??? ??? ??? maybe a lack of lubricant...???

The dove tail where completely distorted..so I decided to save my works following the Bogs idea regarding one useful thread tool holding...So I removed the wrong dovetail and...After few hour later...I had in my ends this!!!!

The components...

...

...

Now I have to blacksmith ...and do a test!!!!

but after few cutting...this is the results.... ??? ??? ??? maybe a lack of lubricant...???

The dove tail where completely distorted..so I decided to save my works following the Bogs idea regarding one useful thread tool holding...So I removed the wrong dovetail and...After few hour later...I had in my ends this!!!!

The components...

Now I have to blacksmith ...and do a test!!!!