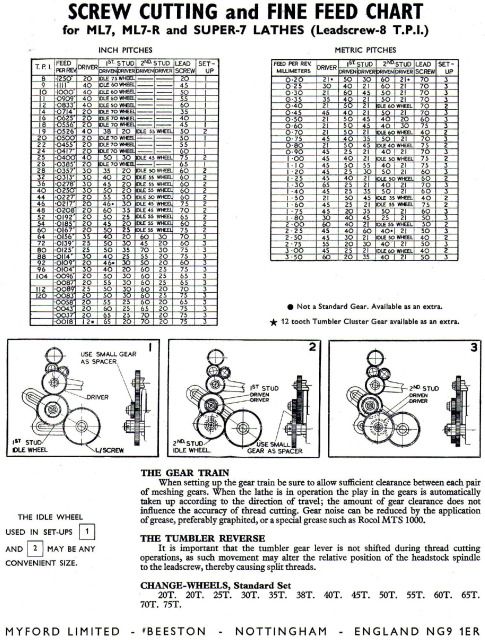

I need to know the factory settings for the gear train configuration of a myford

ML7.

When working the machine the carriage seems to travel too fast and leaves the work as if it's been screw cut, so need to know the numbers of the cogs on gear train and their order?

Thanks in advance

Gavin

ML7.

When working the machine the carriage seems to travel too fast and leaves the work as if it's been screw cut, so need to know the numbers of the cogs on gear train and their order?

Thanks in advance

Gavin