rklopp

Well-Known Member

- Joined

- Oct 6, 2008

- Messages

- 393

- Reaction score

- 109

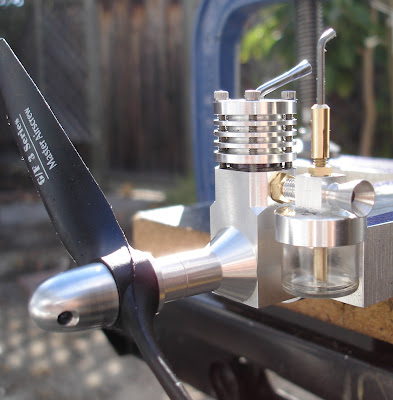

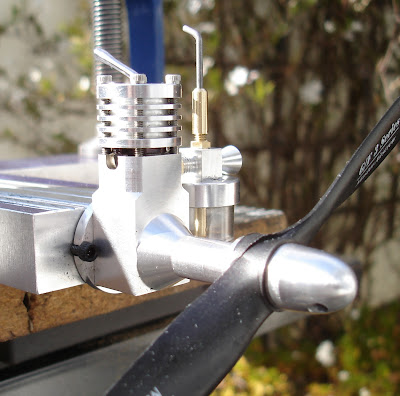

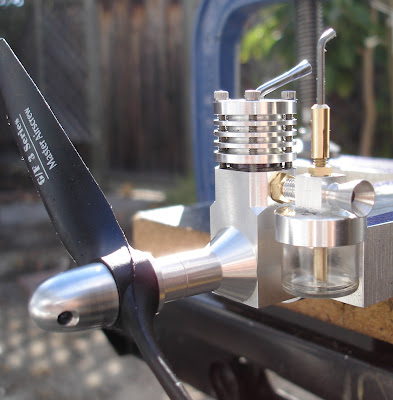

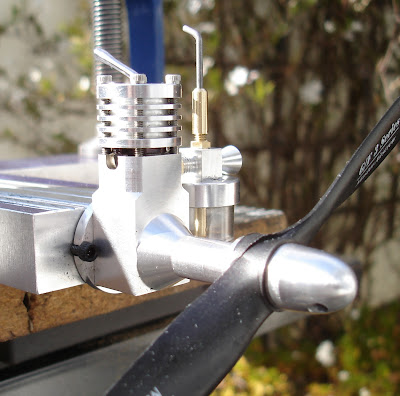

Today I finished an ML Midge and got it running. This is my first "diesel."

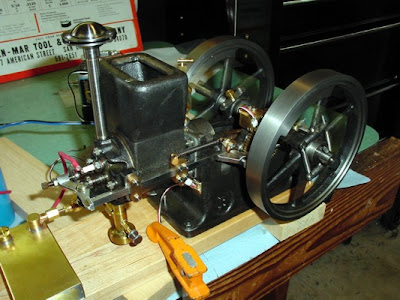

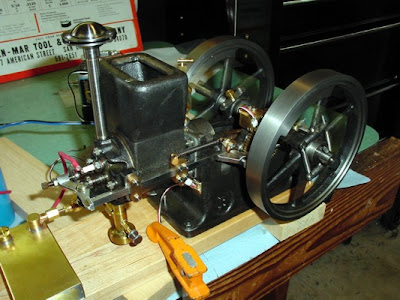

My first IC engine was a Little Dragon, shown below. I built it in the midst of building a Breisch Associated Hired Man hit-and-miss, also shown below.

I bought the Hired Man castings from Paul in his basement when I was starting grad school around 1981. Between getting educated, married, housed, and siring offspring, it took about 20 years to complete the Hired Man. When I started building it, I had no machinery of my own. Now I have a bunch.

Some videos:

[ame]http://www.youtube.com/watch?v=tMjwd7bHsYw[/ame]

[ame]http://www.youtube.com/watch?v=lcDQTn54S50[/ame]

[ame]http://www.youtube.com/watch?v=jzdr4UhMGwI[/ame]

My first IC engine was a Little Dragon, shown below. I built it in the midst of building a Breisch Associated Hired Man hit-and-miss, also shown below.

I bought the Hired Man castings from Paul in his basement when I was starting grad school around 1981. Between getting educated, married, housed, and siring offspring, it took about 20 years to complete the Hired Man. When I started building it, I had no machinery of my own. Now I have a bunch.

Some videos:

[ame]http://www.youtube.com/watch?v=tMjwd7bHsYw[/ame]

[ame]http://www.youtube.com/watch?v=lcDQTn54S50[/ame]

[ame]http://www.youtube.com/watch?v=jzdr4UhMGwI[/ame]