I've posted this on another forum but figured it may also be of interest here.

In the future I want to to and make a clock and one of the features of quality clocks is all the screws are 'blued'

I've also got a Bing steam engine to restore that would of originally had Japanned and blued surfaces on it so will be bluing all my replacement screws on it.

Here is a 6BA screw straight out of the packet.

Before it can be blued it needs to be polished so here is an 'Emery Stick' I made to help.

The side showing has 600 W&D on it and the underside has 1200 W&D

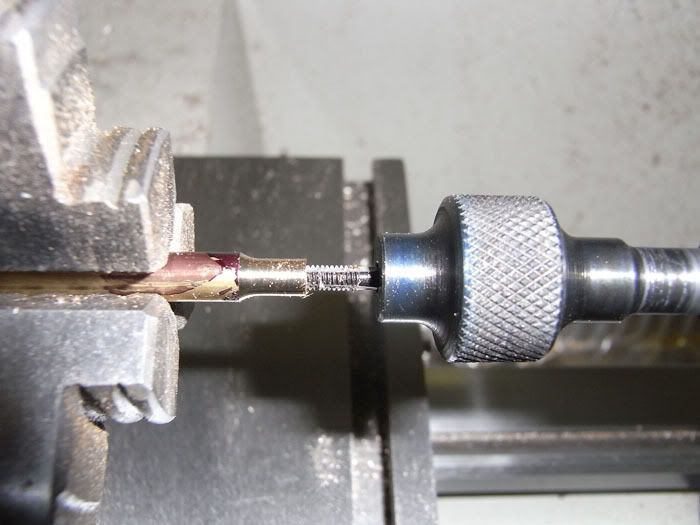

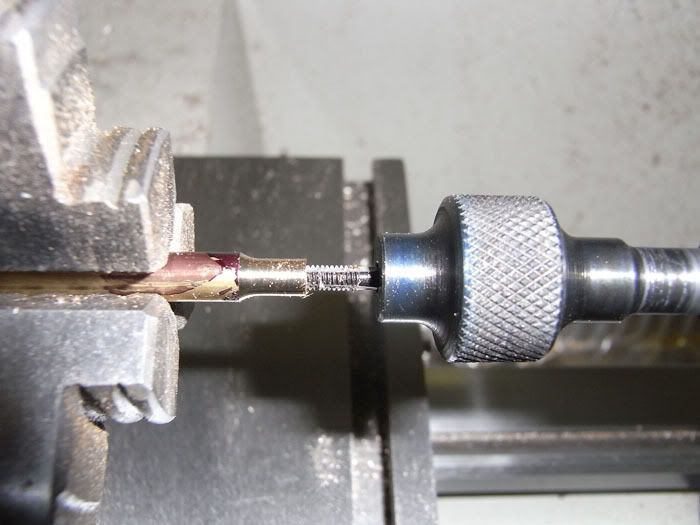

Next I needed to make a jig to hold the 6BA screws.

This consisted of a brass rod turned down so the diameter was less than the diameter of the head of the screw. It was then drilled and tapped.

Here is the tapping tool I made a few weeks back being used.

Out of the packet screw in the jig

Screwed after being lightly skimmed

Here the left hand screw has been skimmed and then polished with the 600 and 1200 W&D 'emery stick' whilst in the lathe, the right is one out of the packet.

Getting ready to blue it.

I felt I had to use this hand vice as it was my great grandfathers who was a watchmaker.

To blue I simply hold the bottom of the screw over my meths burner until the top reaches the colour I want.

It first goes yellow and then 'like magic' a lovely blue colour just appears.

Close up before bluing.

Here is is 'Blued'

Job done

In the future I want to to and make a clock and one of the features of quality clocks is all the screws are 'blued'

I've also got a Bing steam engine to restore that would of originally had Japanned and blued surfaces on it so will be bluing all my replacement screws on it.

Here is a 6BA screw straight out of the packet.

Before it can be blued it needs to be polished so here is an 'Emery Stick' I made to help.

The side showing has 600 W&D on it and the underside has 1200 W&D

Next I needed to make a jig to hold the 6BA screws.

This consisted of a brass rod turned down so the diameter was less than the diameter of the head of the screw. It was then drilled and tapped.

Here is the tapping tool I made a few weeks back being used.

Out of the packet screw in the jig

Screwed after being lightly skimmed

Here the left hand screw has been skimmed and then polished with the 600 and 1200 W&D 'emery stick' whilst in the lathe, the right is one out of the packet.

Getting ready to blue it.

I felt I had to use this hand vice as it was my great grandfathers who was a watchmaker.

To blue I simply hold the bottom of the screw over my meths burner until the top reaches the colour I want.

It first goes yellow and then 'like magic' a lovely blue colour just appears.

Close up before bluing.

Here is is 'Blued'

Job done