rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 125

I walked though the machine shop at work yesterday and was a little displeased to see this.

The power was on and the lathe was in gear.

Just made me want to reach out and touch someone.

Apparently a maintenance man had used the lathe to drill a hole.

He also removed the QCTP from the cross slide.

I have no idea why.

And, the tail stock was in the middle of the machine and not locked in place.

Did I say displeased?

Maybe a little past that....

You can't fix stupid but you can slow it down.

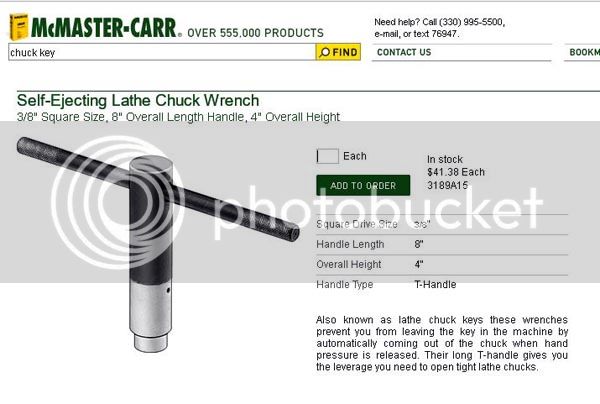

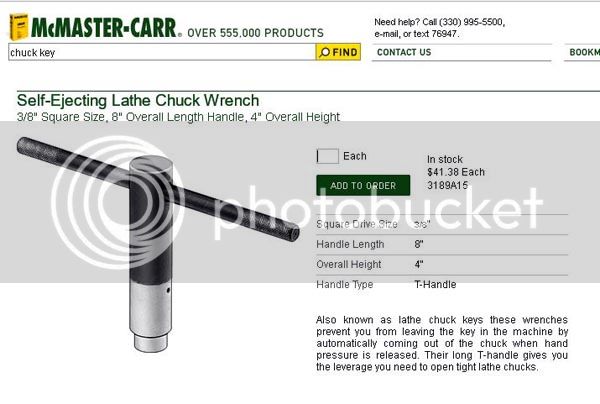

This will be at that lathe by noon tomorrow.

Maybe I'm just getting too old and cranky to be patient about ridiculous safety oversights.

The power was on and the lathe was in gear.

Just made me want to reach out and touch someone.

Apparently a maintenance man had used the lathe to drill a hole.

He also removed the QCTP from the cross slide.

I have no idea why.

And, the tail stock was in the middle of the machine and not locked in place.

Did I say displeased?

Maybe a little past that....

You can't fix stupid but you can slow it down.

This will be at that lathe by noon tomorrow.

Maybe I'm just getting too old and cranky to be patient about ridiculous safety oversights.