Naiveambition

Well-Known Member

- Joined

- May 15, 2012

- Messages

- 369

- Reaction score

- 95

Ive been trying to read Chinese wiring diagrams and well.....:wall::wall::wall:

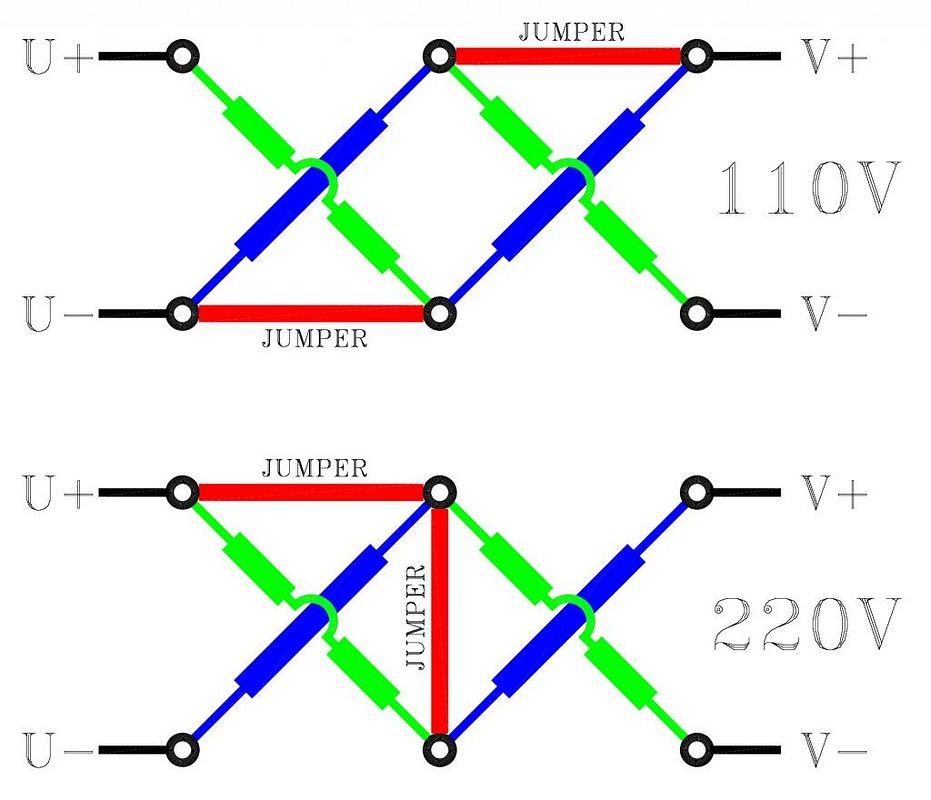

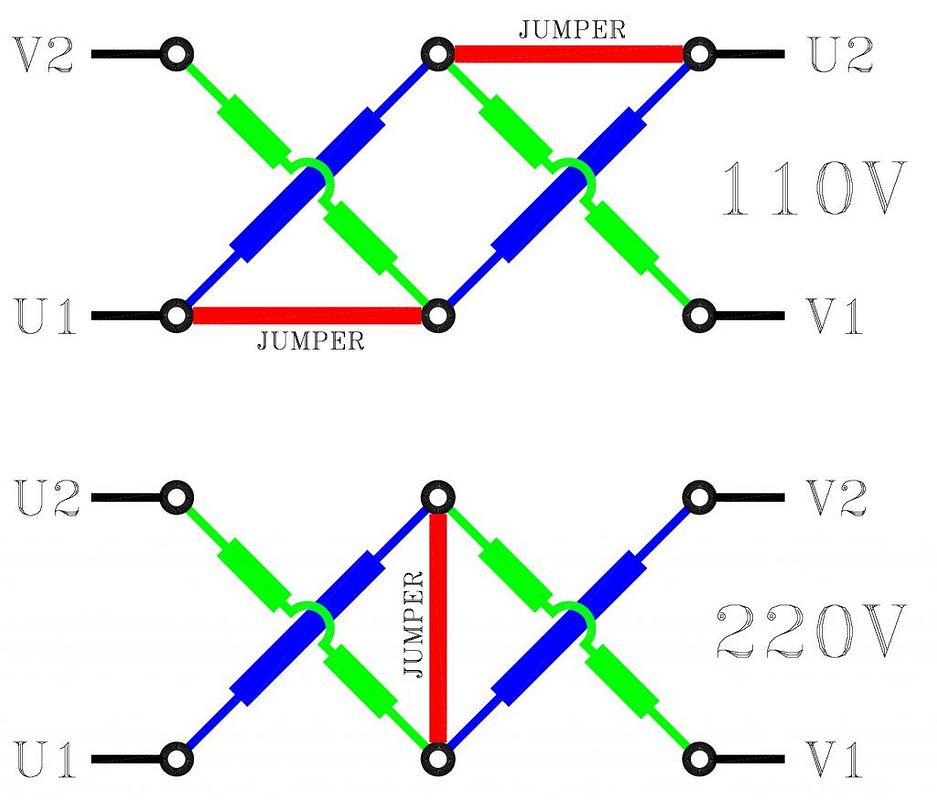

I've found a better version on bolton tools website. I am trying to hook up to 220v, and machine is now 110v.

From the book it gives pics of the on/off switch from top and side angles. I understand how to switch the motor controller to 220v, so my question is would you also have to rewire the on/off forward/reverse switch also.?

The manual has me thinking that the switch would be wired both voltages and just change the motor controller contacts.

I can't post the website or the PDF. so here is a pic of what I have, same as manual. This is the top rear of the switch.

Thanx for any help

I've found a better version on bolton tools website. I am trying to hook up to 220v, and machine is now 110v.

From the book it gives pics of the on/off switch from top and side angles. I understand how to switch the motor controller to 220v, so my question is would you also have to rewire the on/off forward/reverse switch also.?

The manual has me thinking that the switch would be wired both voltages and just change the motor controller contacts.

I can't post the website or the PDF. so here is a pic of what I have, same as manual. This is the top rear of the switch.

Thanx for any help