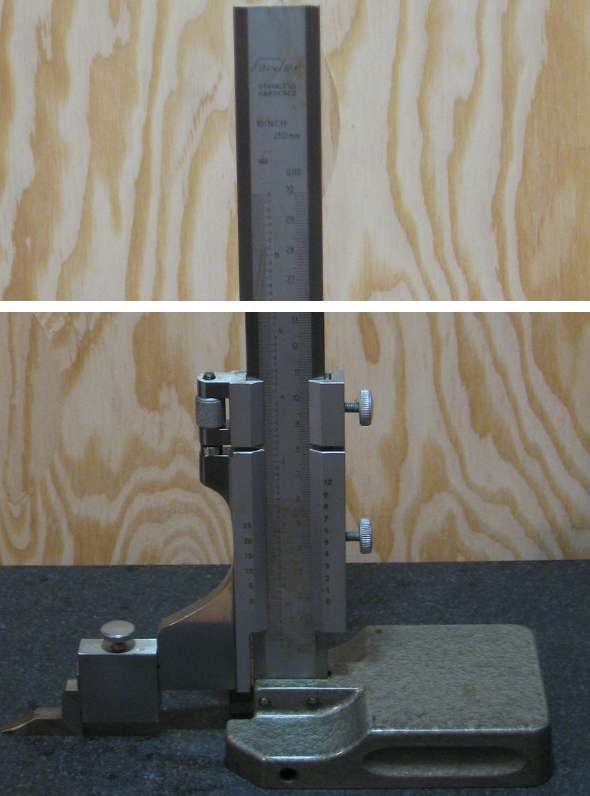

A while back I bought a 10"/250mm vernier height gauge on eBay. It is marked "Fowler" but has no model number on it so I had no luck with an online search for a manual.

Yesterday while struggling to mark out the little rectangular block of brass that is to become a cylinder for my Elmer's wobbler using an odd-leg, a scriber, a square and only two hands I decided it was time to quit being a masochist and to figure out how to use the height gauge instead.

There were three items in the fitted box seen here still covered in packing grease. With the 'foot ?' flat against the surface plate the vernier read 0.

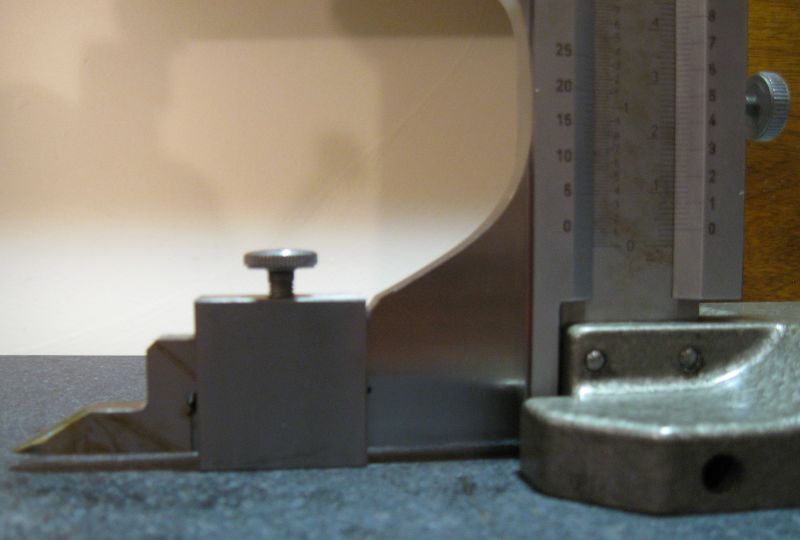

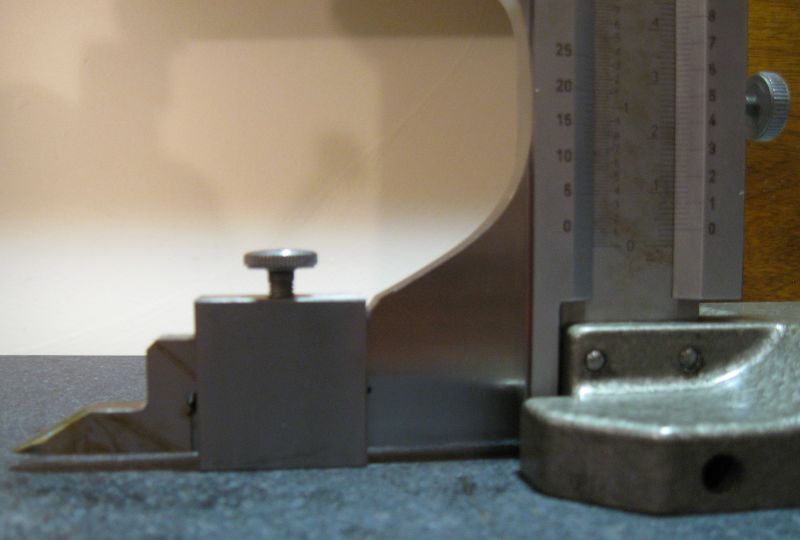

how hard could it be to assemble, but looking closely once assembled the clamp that holds the scriber to the 'foot' raises the scriber and the zero by approximately 3mm.

I am probably doing something really stupid, but surely there must be away of adjusting the zero, or affixing the scriber some other way?

On a related note how does one read the height gauge while wearing bifocals? The alternatives seem to be a neck brace to ease the cramps in one's neck after twisting it into pretzel while getting ones eyes level with the vernier else a good pair of tweezers for picking out the bits of swarf from kneeling knee deep in it

Thanks,

Clive

Yesterday while struggling to mark out the little rectangular block of brass that is to become a cylinder for my Elmer's wobbler using an odd-leg, a scriber, a square and only two hands I decided it was time to quit being a masochist and to figure out how to use the height gauge instead.

There were three items in the fitted box seen here still covered in packing grease. With the 'foot ?' flat against the surface plate the vernier read 0.

how hard could it be to assemble, but looking closely once assembled the clamp that holds the scriber to the 'foot' raises the scriber and the zero by approximately 3mm.

I am probably doing something really stupid, but surely there must be away of adjusting the zero, or affixing the scriber some other way?

On a related note how does one read the height gauge while wearing bifocals? The alternatives seem to be a neck brace to ease the cramps in one's neck after twisting it into pretzel while getting ones eyes level with the vernier else a good pair of tweezers for picking out the bits of swarf from kneeling knee deep in it

Thanks,

Clive