DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 45

I'm unsure if other X-3's came like mine with no way of properly tightening the 3 handles on the quill feed. I've been twisting them by hand for 2 years now....the whole time saying to myself "Geez, just mill a couple flats so you can torque 'em down with a wrench." Sounds easy but I never got around to it 'til today. I didn't want to just clamp them in the vice without a way of accurately indexing the flats.

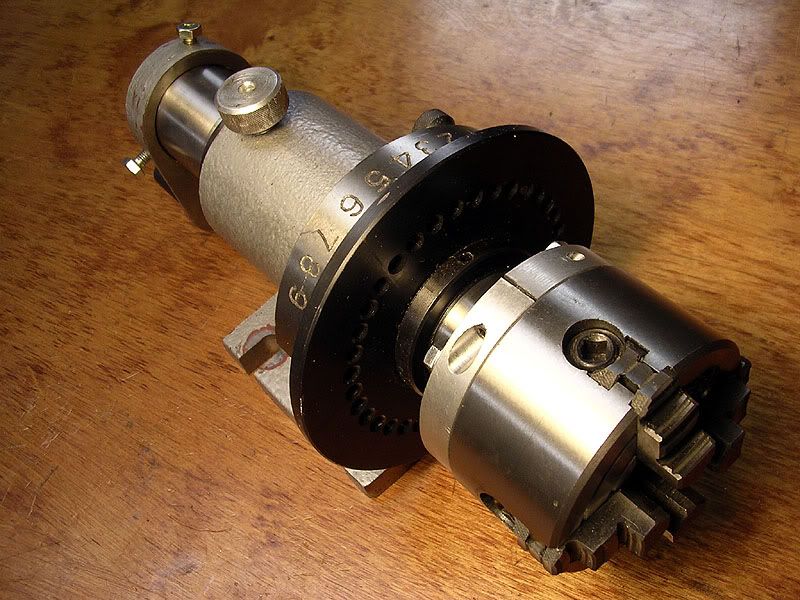

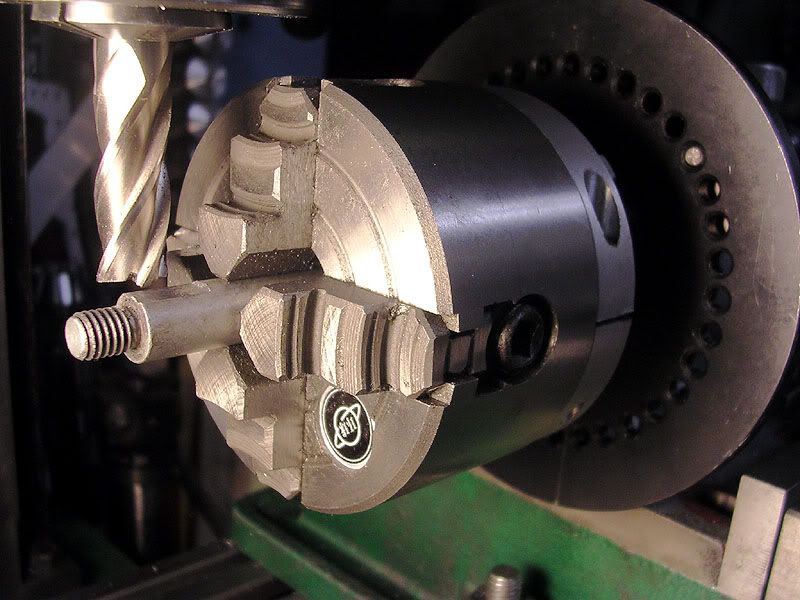

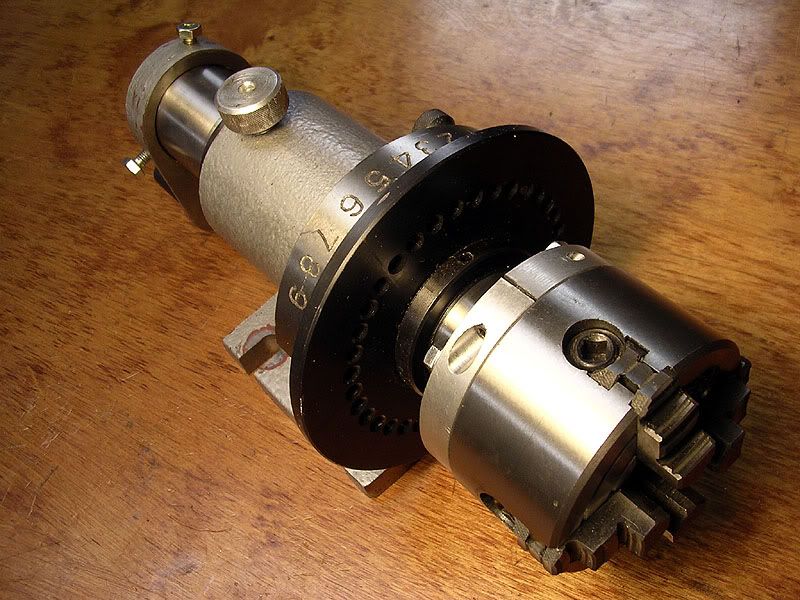

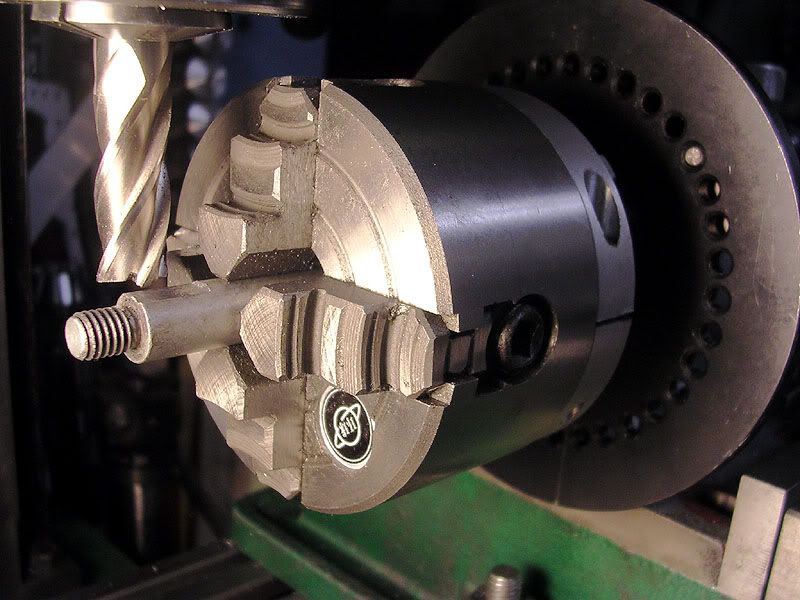

I turned an adapter to put my LMS 3" 4-jaw on my spin indexer today, chucked up the handles and milled the flats. I made them so a 10 mm wrench (to match the metric theme) fits snugly and they tightened up real well. Problem solved.

I turned an adapter to put my LMS 3" 4-jaw on my spin indexer today, chucked up the handles and milled the flats. I made them so a 10 mm wrench (to match the metric theme) fits snugly and they tightened up real well. Problem solved.