GordTopps

Well-Known Member

- Joined

- Jun 3, 2009

- Messages

- 145

- Reaction score

- 1

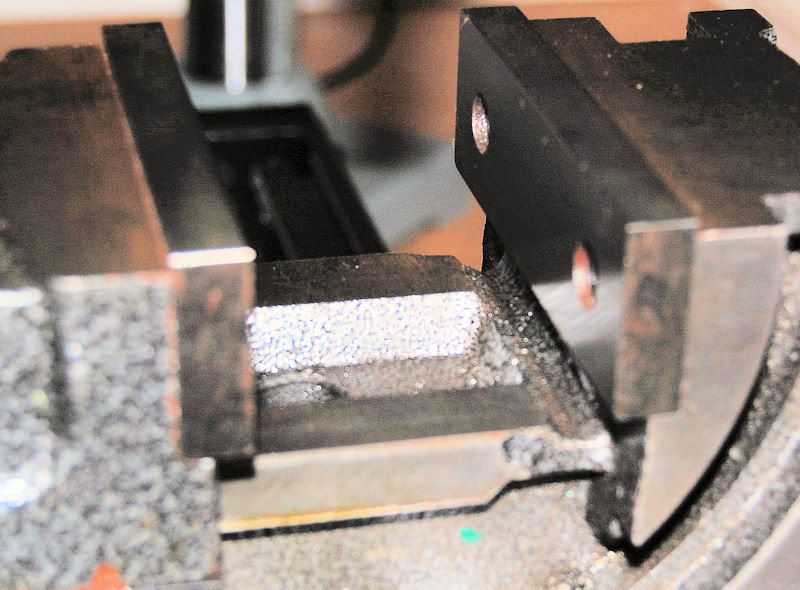

It looks like I made a bad decision in my choice of vice.

Only found this out when I tried to use my thin parallels with this vice.

My parallels are 1/8" x aaa" x 6"

Hope this pic shows what I mean.

The parallel will not fit on the bedways next to the fixed jaw, there is about a 1/4" gap.

It looks like my options are:

a) make new jaw using guage plate (or similar) about 1/4" thicker than original.

b) make a spacer of about 1/4" to fit behind the original fixed jaw.

What are your options? What would you do?

Many thanks for any advice.

Gordon

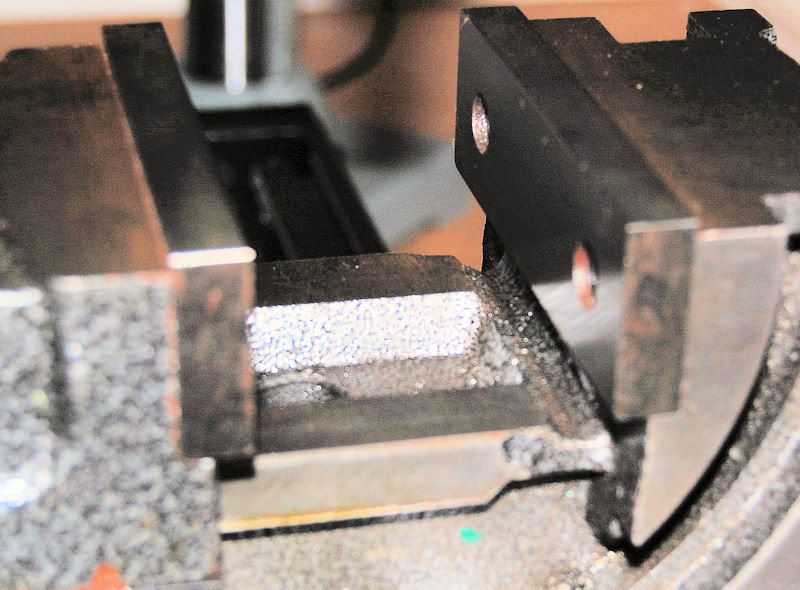

Only found this out when I tried to use my thin parallels with this vice.

My parallels are 1/8" x aaa" x 6"

Hope this pic shows what I mean.

The parallel will not fit on the bedways next to the fixed jaw, there is about a 1/4" gap.

It looks like my options are:

a) make new jaw using guage plate (or similar) about 1/4" thicker than original.

b) make a spacer of about 1/4" to fit behind the original fixed jaw.

What are your options? What would you do?

Many thanks for any advice.

Gordon