I realise that the members of this forum seem to have an aversion to anything to do with woodwork  , but stick with me and go along for the ride. Here in the Land of Oz, we have a native tree called a River Red Gum. The wood of this tree is so hard and dense that it is generally only used for fence posts, railway sleepers/ties, and firewood. However, one enterprising gentleman has found a new use based on the fact that a wood this hard could be treated like metal and maybe machined in all the similar ways. He has started making scale models of machinery almost entirely of wood, for all possible moving parts etc, only using metal where absolutely necessary. As exhibit one I present a twin cylinder Tangye winching engine in its full size;

, but stick with me and go along for the ride. Here in the Land of Oz, we have a native tree called a River Red Gum. The wood of this tree is so hard and dense that it is generally only used for fence posts, railway sleepers/ties, and firewood. However, one enterprising gentleman has found a new use based on the fact that a wood this hard could be treated like metal and maybe machined in all the similar ways. He has started making scale models of machinery almost entirely of wood, for all possible moving parts etc, only using metal where absolutely necessary. As exhibit one I present a twin cylinder Tangye winching engine in its full size;

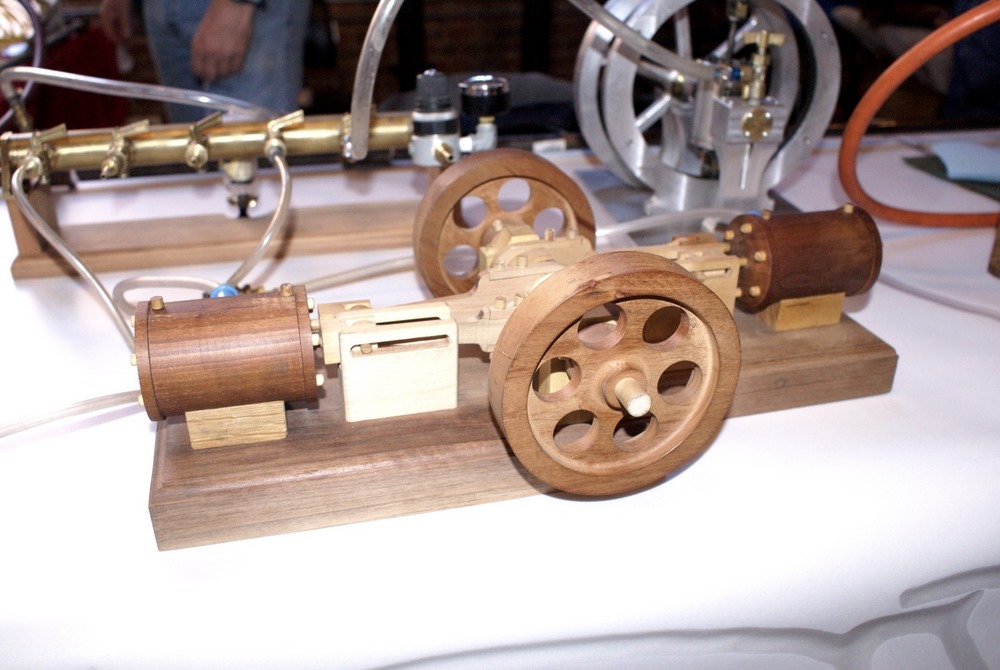

Followed by a quarter scale model about 16"/400mm high;

The crankshaft turns, all the valve gear operates, everything happens as it should.

Next, a scale traction engine not much more than 12"/300mm long.

Finally, just a close up of the tracks on a crawler tractor, each link is a little over 1"/25mm long and the whole track moves correctly if the model is pushed along.

So, woodwork is not just doll's houses and garden swings afterall.

Ian.

Followed by a quarter scale model about 16"/400mm high;

The crankshaft turns, all the valve gear operates, everything happens as it should.

Next, a scale traction engine not much more than 12"/300mm long.

Finally, just a close up of the tracks on a crawler tractor, each link is a little over 1"/25mm long and the whole track moves correctly if the model is pushed along.

So, woodwork is not just doll's houses and garden swings afterall.

Ian.