You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

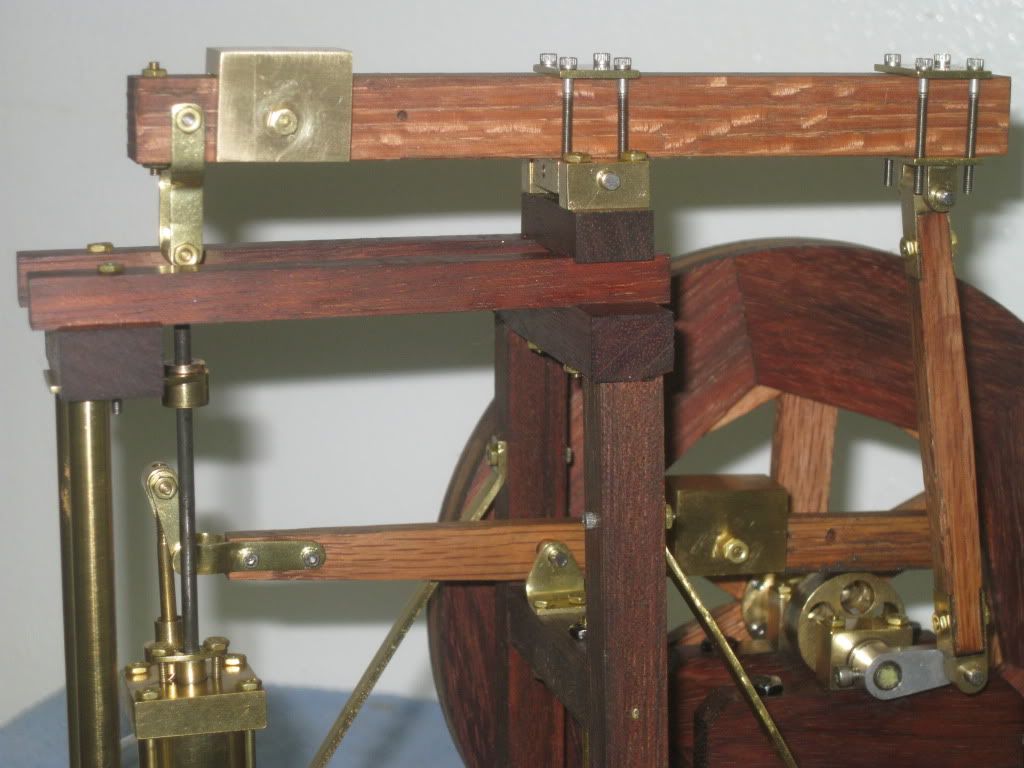

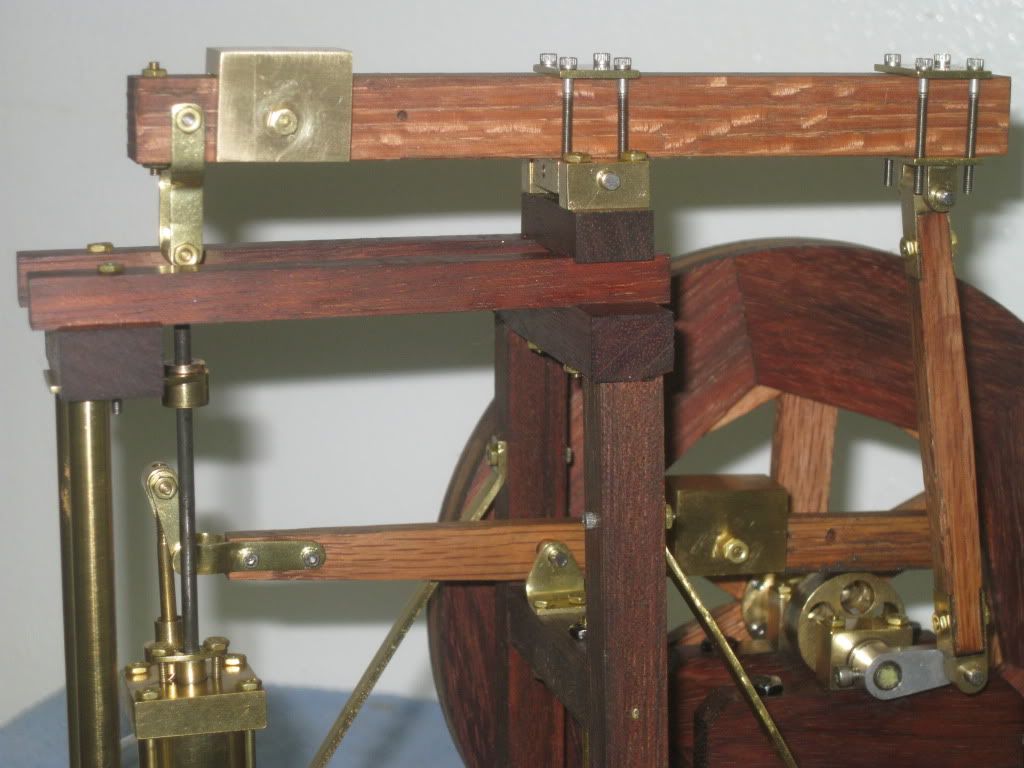

Wood Beam Engine fabricated by SAM

- Thread starter SAM in LA

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Absolutely woodnerful Sam.

A great looking and running engine, made from something not normally associated with what we do.

Very admirable indeed.

John

A great looking and running engine, made from something not normally associated with what we do.

Very admirable indeed.

John

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Great job Sam ;D - Well Done indeed! :bow:

Kind regards, Arnold

You Betcha! - It does get easier ;DI'm sure the next time I need to silver solder it will be much easier.

Kind regards, Arnold

Maryak said:Sam,

A Wobwass Bweam Engine wunning wiff all the awe and majesty, (most woyals have a wisp), such elegant machines deserve. BWEUTIFUL :bow: :bow:

Best Regards

Bob

Bob,

Thanks for the endorsement. I never suspected that I was amongst woyalty.

SAM

kcmillin said:Great Job Sam!!

She is a real run one to watch, and easy on the eyes.

Well Done Thm:

Kel

Kel,

I like the wood and brass too.

I may use a wooden flywheel on another engine if the future.

Regards,

SAM

Good job Sam!!! I like it.----Brian

Deanofid said:Wonderfully done, Sam!

Dean

Dean,

Thanks.

When I think about what I went through to silver solder parts on my engine, then look at what you did on your engine, it sends chills up my neck.

SAM

Bogstandard said:Absolutely woodnerful Sam.

A great looking and running engine, made from something not normally associated with what we do.

Very admirable indeed.

John

John,

"woodnerful" Rof}

Your kind words mean a lot to an amateur like myself.

Thanks,

SAM

arnoldb said:Great job Sam ;D - Well Done indeed! :bow:

You Betcha! - It does get easier ;D

Kind regards, Arnold

Arnold,

Thanks.

Please note that I haven't mixed up anyones names so far today. ;D

Regards,

SAM

GordTopps said:Wonderful SAM :bow:

I love beam engines, a truly gr8 example.

Regards

Gordy

Gordy,

I like beam engine too.

Thanks for the compliment.

SAM

Brian Rupnow said:Good job Sam!!! I like it.----Brian

Brian,

I changed the engine timing a bit and it runs a lot better.

Thanks,

SAM

RichD said:Nice job Sam!

Nothing like that choo choo sound to make a gearhead smile.

Rich

Rich,

I like the sound of it too.

Thanks,

SAM

SAM in LA said:Well, this is it.

This video shows the engine running a lot slower than the previous one.

[...]

I love it when it runs very slowly.

tom in MA

ttrikalin said:I love it when it runs very slowly.Means you made it very well. I like the finish. Thank you for this thread. :bow:

tom in MA

Tom,

Thanks.

Friction is this engines biggest enemy.

Getting everything square is the trick to having it run slowly.

I am planning to post more of the build log, once it is written.

SAM

Today I was able to get this engine to run smoothly at 48 RPM.

[ame]http://www.youtube.com/watch?v=9AWVbPX2B2A[/ame]

I did a number of things to achieve this low speed.

I was looking for some material to make a counterweight for the valve beam and a counterweight for the power piston beam. It turned out that the material was right in front of me all the time. The weights were hiding in a piece of 3/8" x 1" brass bar stock. I cut off three pieces, silver brazed them together and milled off the excess.

The valve beam weight is moved to achieve the minimum force required so the beam stays in contact with the eccentric.

I also used some powdered graphite on the area of the valve beam that contacts the eccentric.

I also added a weight to the power piston beam. This weight seems to help the engine get past the point where the crank shaft wants to stick at TDC.

What really freed it up though was when I loosened up the head bolts on the power piston. I discovered this by accident when I was checking to see if they were tightened evenly. I left them finger tight.

This was an interesting project and as I watch it run I see pieces that I know I can make better or little tweaks that may help it to run better. I may try to add some weight to the flywheel. Perhaps that will smooth out the rotation so it doesn't try to stop when the crank is TDC.

Thanks for stopping buy to visit.

SAM

[ame]http://www.youtube.com/watch?v=9AWVbPX2B2A[/ame]

I did a number of things to achieve this low speed.

I was looking for some material to make a counterweight for the valve beam and a counterweight for the power piston beam. It turned out that the material was right in front of me all the time. The weights were hiding in a piece of 3/8" x 1" brass bar stock. I cut off three pieces, silver brazed them together and milled off the excess.

The valve beam weight is moved to achieve the minimum force required so the beam stays in contact with the eccentric.

I also used some powdered graphite on the area of the valve beam that contacts the eccentric.

I also added a weight to the power piston beam. This weight seems to help the engine get past the point where the crank shaft wants to stick at TDC.

What really freed it up though was when I loosened up the head bolts on the power piston. I discovered this by accident when I was checking to see if they were tightened evenly. I left them finger tight.

This was an interesting project and as I watch it run I see pieces that I know I can make better or little tweaks that may help it to run better. I may try to add some weight to the flywheel. Perhaps that will smooth out the rotation so it doesn't try to stop when the crank is TDC.

Thanks for stopping buy to visit.

SAM

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 30

- Views

- 3K