Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

Tin, It must surely be frustrating. I have all but given up buying second hand tools on eBay because invariably there is always something wrong or mis described.

I guess I better stop posting about building on a shopping thread but this is what I achieved.

Rod I blame myself as much as the seller. He could have mentioned there was no power supply . He DID say no accessories. I did not notice there was no PS in the photo. On the plus side the unit was packed in the original carton with original packing. and so far one missing screw that needed to be replaced. And a couple parts had fallen off the machine but were there.

e-bay and auctions is one of those times when you need to stay objective. Get caught in the excitement and one can pay too much or miss details I missed a $50 detail it cost me.

Say the word and I can breakout your build posts into a new thread.

and my shopping thread has turned into getting a used machine running thread. . when I get power I will likely break off into a new thread as well and add some things I learned about what is out there to this thread.

Good bad or indifferent I hope people have learned from this thread , and the choices I made. As well as the various advise given.

Part of my logic was getting started and not spending to much time on research. there comes a time when one has to stop the talk and start to walk. Looks like you are walking.

Again thanks to all who are helping in this journey. I know there are a bunch of guys with these machines and not a lot of talk about them.

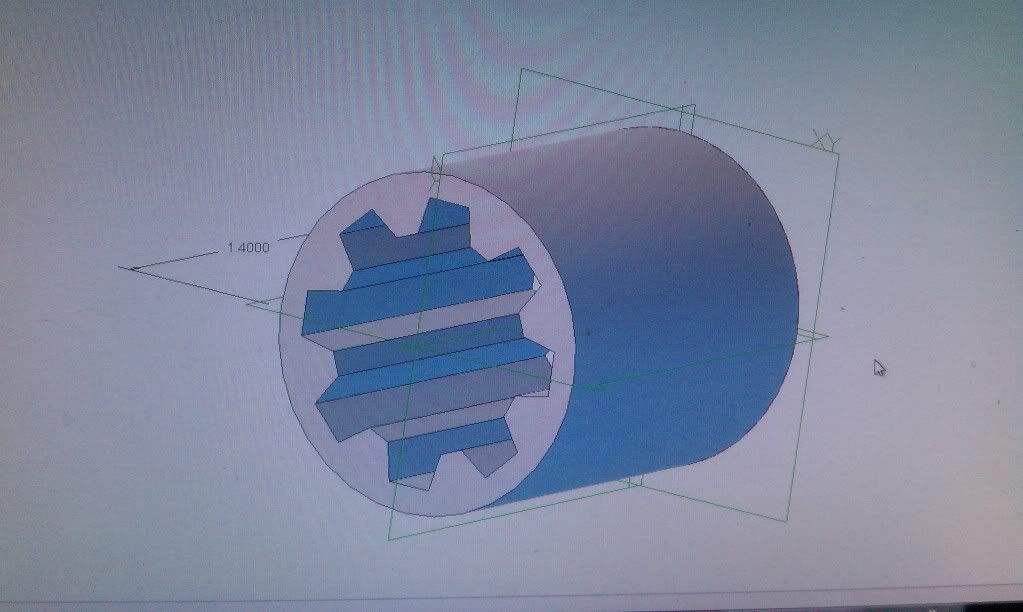

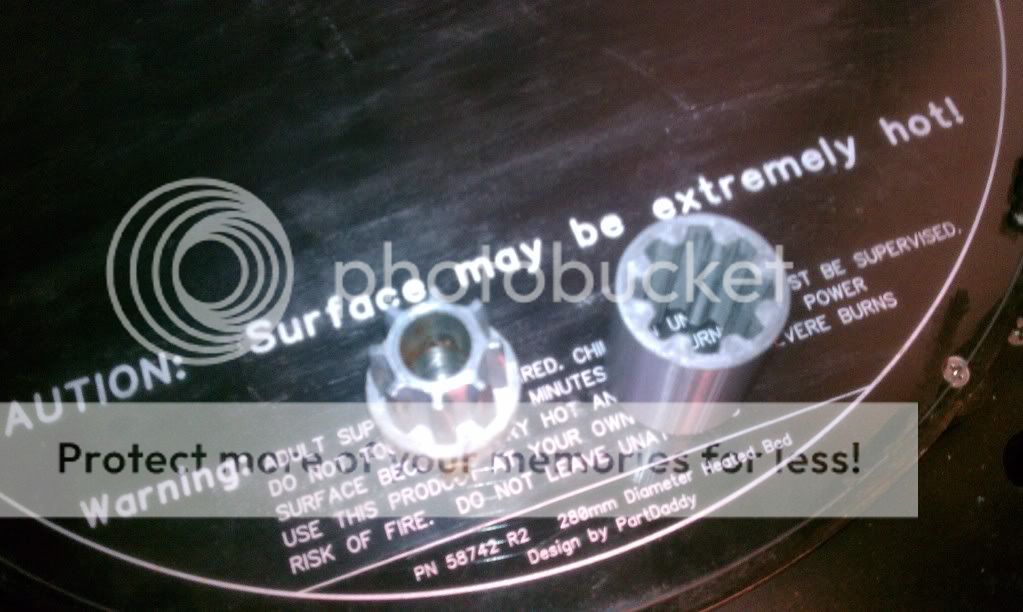

I know it is an additive process and not metal removal but CNC and Something found more and more in the home shop. 5 years ago a reprap kit was about 1 k and looked like scaffolding on the side of a building. The technology is changing.

IMHO there is lots of research to be done with materials. And I have been told the software has come a long way but still much room for improvement.

Tin