Yesterday when I was at the steam show in Muskoka, thre were many old steam toys that were driven by little steam engines. They all used drive belts that appeared to be about .060 to.080" diameter round fabric covered material. Does anybody know---what was it --- and where to get it---and can it be cut to size and spliced? These tiny engines don't develop a whole lot of power, so whatever this miniature belting is, it must bend very easily but still have a high enough coefficient of friction to drive things properly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What to use for miniature drive belts???

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi Brian

There are many different types of miniature drivebelts that can be used:

-small spring (wilesco does sell them)

-o-rings

I think i have seen that kind of belt you are looking for on ebay, if its the same, then you can easily splice it:

-cut the ends

-heat with a lighter

-press slightly together

-cut the overlapping material

or

-use some instant cement to glue the ends together (that one for rubber)

The same material is being used to drive watchmakers lathes. But it then has a diameter of 4mm / 0.160"

Florian

There are many different types of miniature drivebelts that can be used:

-small spring (wilesco does sell them)

-o-rings

I think i have seen that kind of belt you are looking for on ebay, if its the same, then you can easily splice it:

-cut the ends

-heat with a lighter

-press slightly together

-cut the overlapping material

or

-use some instant cement to glue the ends together (that one for rubber)

The same material is being used to drive watchmakers lathes. But it then has a diameter of 4mm / 0.160"

Florian

It seems I have answered my own question!! I did a web search and came up with this---

http://www.toysteamengine.com/

http://www.toysteamengine.com/

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

McMaster Carr has

3/16 diameter spring beltingand connectors

1/16 diameter endless o ring belts

urethane belting material as small as 3/32 for solid and 3/16 for hollow core

leather belting as small as 1/8

Tin

3/16 diameter spring beltingand connectors

1/16 diameter endless o ring belts

urethane belting material as small as 3/32 for solid and 3/16 for hollow core

leather belting as small as 1/8

Tin

mklotz

Well-Known Member

PMR sells miniature (~0.25" wide) flat belting for use with their miniature belt-driven machine tools.

B

Bogstandard

Guest

For the recyclers amongst you, old tape decks and walkmans usually have a few very small belts in them, belt driven record decks have very nice flat belting that can be cut to length and joined with someting as simple as sellotape or even duct tape.

John

John

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

I was killing time at WalMart one day while the wife was shopping.

The dog EXPECTS a toy when when we come home so I was in the pet area.

I saw a cat collar that looked exactly like a miniature flat belt.

I don't know just how long I'd been standing there working out a way to

stitch that collar into a belt.

Long enough for a WalMart associate to come over and ask if I need help! :big:

Rick

The dog EXPECTS a toy when when we come home so I was in the pet area.

I saw a cat collar that looked exactly like a miniature flat belt.

I don't know just how long I'd been standing there working out a way to

stitch that collar into a belt.

Long enough for a WalMart associate to come over and ask if I need help! :big:

Rick

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Brian

the toy engine use what are known as "spring belts". They come in two styles. the German version screws one end of the spring into the other, while the American versions tend to have interlocking loops on each end. ( a much more secure method) The web site at www.jensensteamemgines.com has them and you can get them easily by calling 800-525-5245 and speaking with the well known Dorita. Yes... they can be cut to length or several can be connected for longer lengths.... which reminds me.... I need to get a few myself.

Steve

the toy engine use what are known as "spring belts". They come in two styles. the German version screws one end of the spring into the other, while the American versions tend to have interlocking loops on each end. ( a much more secure method) The web site at www.jensensteamemgines.com has them and you can get them easily by calling 800-525-5245 and speaking with the well known Dorita. Yes... they can be cut to length or several can be connected for longer lengths.... which reminds me.... I need to get a few myself.

Steve

DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

In all seriousness, I think I read online somewhere that waxed wide tape dental floss makes good media for small drive belts.

Am I going mad or just eating too much cheese? ;D

Al

Am I going mad or just eating too much cheese? ;D

Al

PTsideshow

Well-Known Member

- Joined

- Apr 12, 2008

- Messages

- 503

- Reaction score

- 19

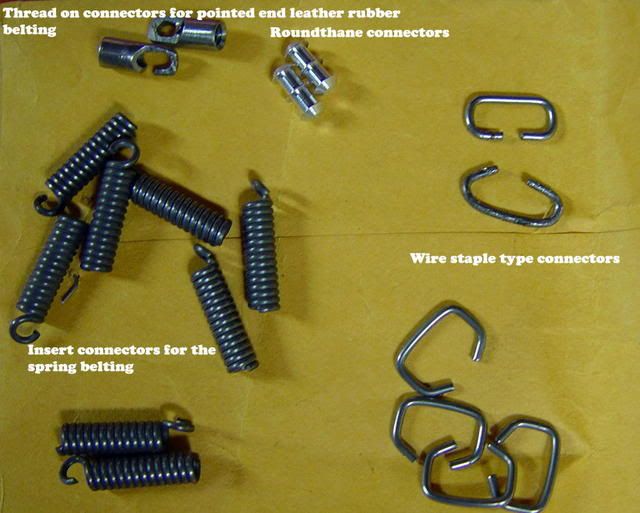

Various connection devices for small belting.

The pliers for leather round belting and hook connectors

Some of the McMaster-Carr selection of belting.

They also have a great selection of chain drive parts.

The leather belting is used on the governor drive of the small working engines like Cretors etc.

Regular O-rings also will work, You can also check with the local place that sell butcher and food service equipment and that does repairs as the leather belts are still used in the equipment.

If you need a small 2mm leather drive belt they have round lace that you can use. the only thing you will have to make up your own tube and hook or hollow connector.

DickDastardly40 said:In all seriousness, I think I read online somewhere that waxed wide tape dental floss makes good media for small drive belts.

Am I going mad or just eating too much cheese? ;D

Al

I've not tried it yet but know of a number of people that have and they all have said good things about it and the best thing has to be the price. One roll of dental floss can make a lot of drive belts. :big:

I had to go over to the south end of town today on business, and I remembered before I left the house that Hercules O-rings have a warehouse and sales outlet over there, so I took my engine with me. the man on the counter was so intrigued by the steam engine that he gave me a 3/32" diameter o-ring for a drive belt, no charge. He had to try a couple of different sizes first, but found a perfect length on the third try. It works very well, and he gave me the o-ring number in case it ever wears out!!!

K

Kludge

Guest

Brian Rupnow said:They all used drive belts that appeared to be about .060 to.080" diameter round fabric covered material. Does anybody know---what was it --- and where to get it---and can it be cut to size and spliced?

Can't say for sure about that but leather's always a good choice. Watchmakers have used roughly 4mm square leather lacing for belts since Noah was a cabin boy although the current trend is to baloney slice and glue rather than staple them together since it reduces the wear on the pulleys. Leather's good stuff since it grabs the pulley surfaces and is tough enough to handle a bunch of abuse. Cows seem to like it anyway.

Taking that as a lead, look around to see if there's any thin leather laying about not doing anything (that you can get away with; cutting up someone's purse et al for the leather is not considered good form. Besides it's usually fake now anyway.) or take a look at a thrift store. Also, leather goods shops have lacing of several orders and round lacing, which is nice for some applications, is also available and isn't all that pricey.

The belts from cassette decks (the better ones since some of the cheapies use what they like to refer as "direct drive"), VCRs, some older camcorders (I don't know about the newer ones.), printers of a fairly broad selection of types, and I think even scanners (most all of which have already been mentioned) are pretty cool as well. Ummm ... it would probably be a real good idea to ensure no one wants them first. Casually informing your first born that his/her printer just gave up its life so your engine driven accessories could live might not play well over dinner.

Best regards,

Kludge

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

I use strips slit from a spindle moulder belt. These are about 6" wide and quite thin. The one on the stamping battery shown in the pic has been in service for for over 20 years now, with quite a few 8 and 10 hour runs included in it's 'log' time

biometrics

Member

- Joined

- Jul 2, 2008

- Messages

- 15

- Reaction score

- 0

Depending on the size, strength and length requirements, "O"-rings are usually available at Home Depot and Lowes in the hardware department. They are usually continuous, seamless neoprene... and not very expensive.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Ok, so, it's an old topic.

Still, I thought I'd mention... a good source of spring belts is an old oil seal, especially a large-diameter axle or crankshaft seal. The rubber sealing lip is backed up by a spring that makes a great small belt, and the spring twists apart with a taper at one end, ready to be joined with others, to form a longer belt.

Still, I thought I'd mention... a good source of spring belts is an old oil seal, especially a large-diameter axle or crankshaft seal. The rubber sealing lip is backed up by a spring that makes a great small belt, and the spring twists apart with a taper at one end, ready to be joined with others, to form a longer belt.

- Joined

- Oct 8, 2007

- Messages

- 151

- Reaction score

- 10

Jerry Howell suggests using mylar audio tape, spliced with cellophane tape. It would seem as though it would be too slippery, but it works for Jerry.

Audio tape looks like scaled down flat belting. O-rings and springs don't. That said, Jerry uses springs for power transmission on one of his personal models.

Orrin

Audio tape looks like scaled down flat belting. O-rings and springs don't. That said, Jerry uses springs for power transmission on one of his personal models.

Orrin

mklotz

Well-Known Member

PMR sells miniature flat belting

http://www.pmresearchinc.com/store/home.php?cat=27

I've used this on my model overhead flat-belt drive system and it works quite nicely with crowned pulleys. It joins easily with super-glue.

http://www.pmresearchinc.com/store/home.php?cat=27

I've used this on my model overhead flat-belt drive system and it works quite nicely with crowned pulleys. It joins easily with super-glue.

Similar threads

- Replies

- 8

- Views

- 9K

- Replies

- 50

- Views

- 23K

- Replies

- 9

- Views

- 8K