You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Water Pressure Engine project

- Thread starter Cedge

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

Steve..... :bow: That is one good looking Wheel.... I do like the curves ;D

Tim is right, Your collection will have a well fitting piece. This really is a very desirable engine you are building, as I said before ' Can't wait to see the finished article' ;D

Just one question... Is a dime really 17.85mm ??? looks significantly smaller to me!

Keep up the outstanding work ;D

Ralph.

Tim is right, Your collection will have a well fitting piece. This really is a very desirable engine you are building, as I said before ' Can't wait to see the finished article' ;D

Just one question... Is a dime really 17.85mm ??? looks significantly smaller to me!

Keep up the outstanding work ;D

Ralph.

B

Bogstandard

Guest

Who's posing for the crowd now Steve?

I won't tell everyone that you can buy them little handwheels at Walmart for 25cents :big: :big: :big:

Joking aside, nice work, now you are well prepared for the big stuff.

Next stop, Marv's flywheel prog.

Bogsie

I won't tell everyone that you can buy them little handwheels at Walmart for 25cents :big: :big: :big:

Joking aside, nice work, now you are well prepared for the big stuff.

Next stop, Marv's flywheel prog.

Bogsie

chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

great job steve..................ignore bogs he's just envious of your work

all joking aside very nice work you should be very proud of your accomplishment's :bow:

chuck

(adding another build to the list) :big:

all joking aside very nice work you should be very proud of your accomplishment's :bow:

chuck

(adding another build to the list) :big:

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Chuck...

I'm cutting Saint Boggler some slack right now. Haven't you heard?.... he ain't got no machine tools?....(innocent grin). I'll get a fair go at him, once he's back in the game for real...LOL

Thanks guys. Here is where I gotta admit to surprising myself. The whole project has gone super well. I'm doing a whole lot of new things that I once doubted I could do. This one has become a real confidence builder, as I get myself cornered and and have to think my way out of the bind.

I must have mentally machined that little hand wheel a few dozen times before I ever chucked up the lathe and another few dozen before it went over to the milling machine. I'm quickly learning to "make one perfect part at a time"..... as one board member's tag line suggested. The results are amazing to me.... and I'm still a little stunned that my own clumsy hands are creating this.

Steve

I'm cutting Saint Boggler some slack right now. Haven't you heard?.... he ain't got no machine tools?....(innocent grin). I'll get a fair go at him, once he's back in the game for real...LOL

Thanks guys. Here is where I gotta admit to surprising myself. The whole project has gone super well. I'm doing a whole lot of new things that I once doubted I could do. This one has become a real confidence builder, as I get myself cornered and and have to think my way out of the bind.

I must have mentally machined that little hand wheel a few dozen times before I ever chucked up the lathe and another few dozen before it went over to the milling machine. I'm quickly learning to "make one perfect part at a time"..... as one board member's tag line suggested. The results are amazing to me.... and I'm still a little stunned that my own clumsy hands are creating this.

Steve

B

Bogstandard

Guest

great job steve..................ignore bogs he's just envious of your work

You wouldn't believe just how much.

I have already told Steve privately how much I admire his work, not just on this engine, but everything he makes. He is starting to becoming a true artisan.

Now about this no machines caper...............

Bogs

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Tony..

Not a problem. I've got plenty of other engines for you to practice your polishing techniques on. Just show up and I'll supply all the polish and flannel...LOL. Having seen your first attempts, it won't be long at all before you are making just about anything you could want. Keep in mind that 3 years ago I'd never even touched a machine tool. I was, however, hell on wheels with my old Chinese drill press...LOL

Thanks for all the kind words

Steve

Not a problem. I've got plenty of other engines for you to practice your polishing techniques on. Just show up and I'll supply all the polish and flannel...LOL. Having seen your first attempts, it won't be long at all before you are making just about anything you could want. Keep in mind that 3 years ago I'd never even touched a machine tool. I was, however, hell on wheels with my old Chinese drill press...LOL

Thanks for all the kind words

Steve

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

Cedge said:Keep in mind that 3 years ago I'd never even touched a machine tool.

Steve

Steve I have been operating machine tools for 30 years and I am simply

amazed by that hand wheel!

That is craftsmanship far beyond the skills of any job shop machinist

I've ever known. Myself included! :bow:

Rick

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Three digit temperature indexes combined with high humidity have made things a bit slow around the shop for a few days, but I've managed to get a little more done. In sad fact, the project is beginning to wind down. I'll be ordering flywheel castings this week so that I can button the little fellow up. Then the final tear down for a careful polishing and some painting will begin.

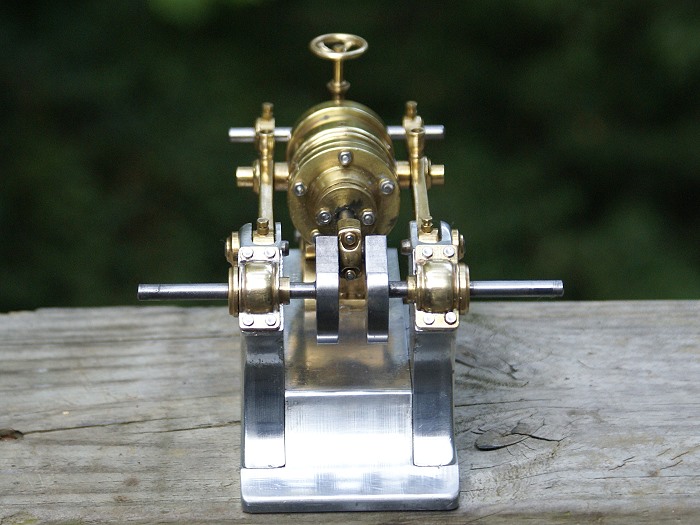

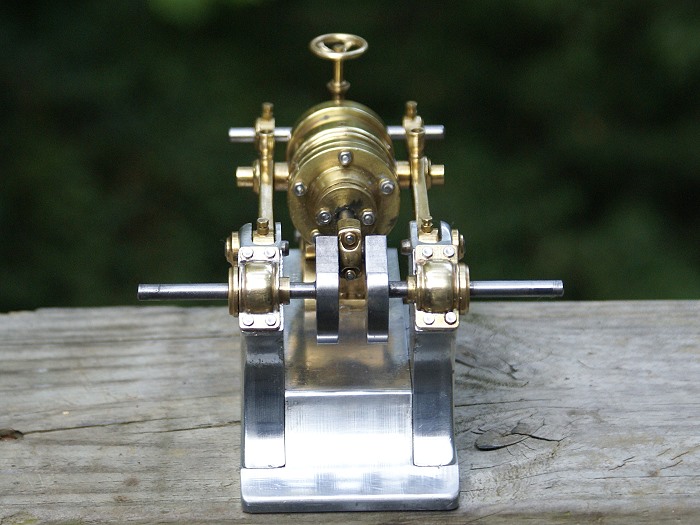

Oilers, lock down bolts and crank bearings were the projects undertaken since I last posted. The oilers are 3/8" tall and 3/16 in diameter. They are working wick type oilers and are only lacking caps to be complete. Two more oilers await mounting and will grace the crank shaft bearing caps when I get back to work. I've still got to fabricate a bleeder bowl for the top of the cylinder and a "pipe flange" to mount the water hammer dome. Like I said... the end of the project is definitely within sight. Below are several views of the recent progress.

Steve

Oilers, lock down bolts and crank bearings were the projects undertaken since I last posted. The oilers are 3/8" tall and 3/16 in diameter. They are working wick type oilers and are only lacking caps to be complete. Two more oilers await mounting and will grace the crank shaft bearing caps when I get back to work. I've still got to fabricate a bleeder bowl for the top of the cylinder and a "pipe flange" to mount the water hammer dome. Like I said... the end of the project is definitely within sight. Below are several views of the recent progress.

Steve

Brass_Machine

Well-Known Member

- Joined

- Aug 28, 2007

- Messages

- 1,314

- Reaction score

- 7

Wow!

:bow: :bow: :bow: :bow: :bow:

Nuff said.

Eric

:bow: :bow: :bow: :bow: :bow:

Nuff said.

Eric

B

Bogstandard

Guest

Ummm, well, I suppose....., not bad, a bit limited, after all it is only a wobbler.

These are a few jealous sort of quotes, but in my view, to start with a few scraps of metal and ragarse line pictures, and also with you being a relative newbie : :big: ;D, I think you deserve my services motto.

:big: ;D, I think you deserve my services motto.

Per Ardua Ad Astra

You know what it means, and you have shown it is possible.

Tongue out and salivating down my t-shirt, waiting for the vid.

Humbled Boglet

These are a few jealous sort of quotes, but in my view, to start with a few scraps of metal and ragarse line pictures, and also with you being a relative newbie :

Per Ardua Ad Astra

You know what it means, and you have shown it is possible.

Tongue out and salivating down my t-shirt, waiting for the vid.

Humbled Boglet

Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

WOW! ..... I'll just spell check that.... WOW!.... Yep thats correct!! ;D :bow: ;D

Ralph.

Ralph.

Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Thanks guys!!

True... she's a humble little wobbler, but at least she's a well dressed one...LOL. Other than a few small little things that only you and I know about, it's been a pretty darned successful project. The last of the oilers were added last night and I've spotted the flywheels I'll be ordering. I'm going to let her rest a day or two before I begin the tear down for the final polishing and clean up phase.

After talking to several engine collectors, a small problem was noted. No one seems to be able to define exactly what style of engine it actually is. It's an oscillator , but not as we commonly see them, so no one seems to know how to classify it once it's put on my web site. So far it's been called a "rocker valve", a "rotary oscillator", a "radial oscillator", a "saddle valve oscillator" and a "hybrid oscillator"..... none of which seem exactly right. Anyone have ideas?

Steve

True... she's a humble little wobbler, but at least she's a well dressed one...LOL. Other than a few small little things that only you and I know about, it's been a pretty darned successful project. The last of the oilers were added last night and I've spotted the flywheels I'll be ordering. I'm going to let her rest a day or two before I begin the tear down for the final polishing and clean up phase.

After talking to several engine collectors, a small problem was noted. No one seems to be able to define exactly what style of engine it actually is. It's an oscillator , but not as we commonly see them, so no one seems to know how to classify it once it's put on my web site. So far it's been called a "rocker valve", a "rotary oscillator", a "radial oscillator", a "saddle valve oscillator" and a "hybrid oscillator"..... none of which seem exactly right. Anyone have ideas?

Steve

B

Bogstandard

Guest

Steve,

Partial Rotary Valve - PRV.

Arc Induced Oscillator - AIO.

Linear Motion Arc Valved Oscillator - LMAVO.

Curved Valve Double Acting Oscillator - CVDAO.

Or even combinations of above.

Partial Rotary Arc Induced Linear Motion Curved Valve Double Acting Oscillator - PRAILMCVDAO.

Do you need any more?, or just maybe call it "The Water Engine" - TWE.

Bogs

Partial Rotary Valve - PRV.

Arc Induced Oscillator - AIO.

Linear Motion Arc Valved Oscillator - LMAVO.

Curved Valve Double Acting Oscillator - CVDAO.

Or even combinations of above.

Partial Rotary Arc Induced Linear Motion Curved Valve Double Acting Oscillator - PRAILMCVDAO.

Do you need any more?, or just maybe call it "The Water Engine" - TWE.

Bogs

mklotz

Well-Known Member

My vote's for AWE - Awesome Water Engine

DickDastardly40

Well-Known Member

- Joined

- Oct 23, 2007

- Messages

- 309

- Reaction score

- 0

Fantastic effort!

I believe it should be referred to as August's Engine of the Month! (or September's if the one above is August's and not July's ;D )

Al

I believe it should be referred to as August's Engine of the Month! (or September's if the one above is August's and not July's ;D )

Al

- Joined

- Jan 1, 2008

- Messages

- 74

- Reaction score

- 0

Great job Steve! Very nice looking engine. Can't wait for the video.

Dick

Similar threads

- Replies

- 77

- Views

- 24K

- Replies

- 14

- Views

- 7K

- Replies

- 115

- Views

- 34K