You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Water Gauges for Boilers.

- Thread starter Tony Bird

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tony Bird

Senior Member

Hi,

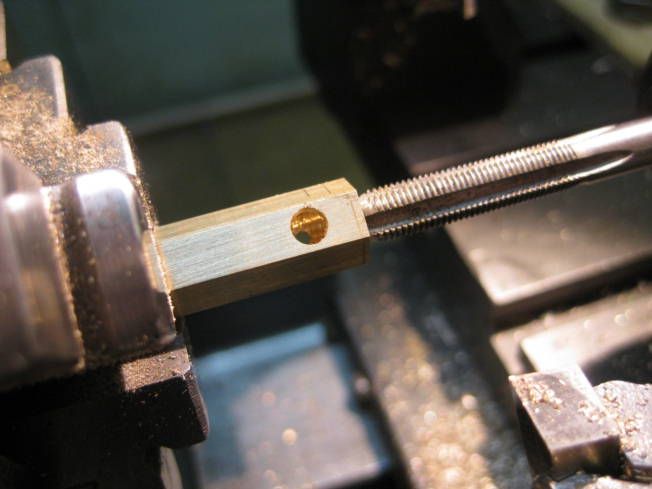

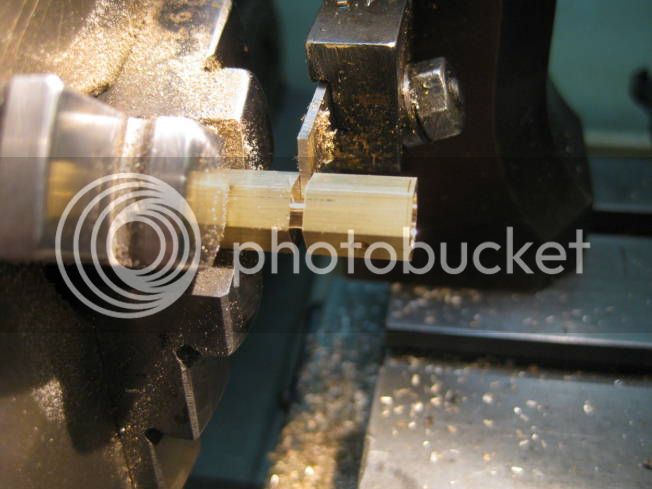

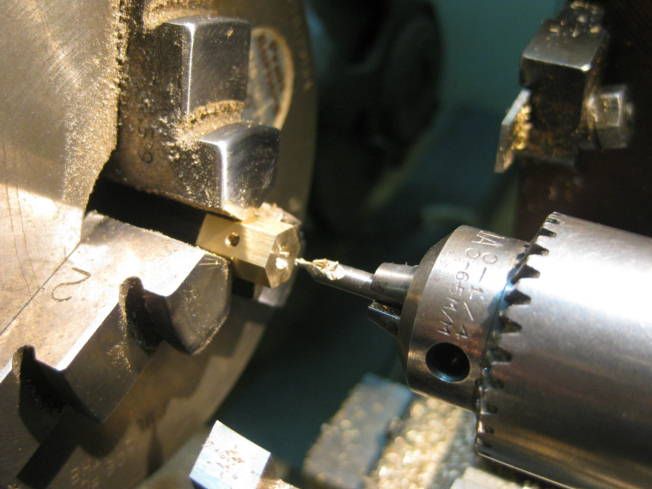

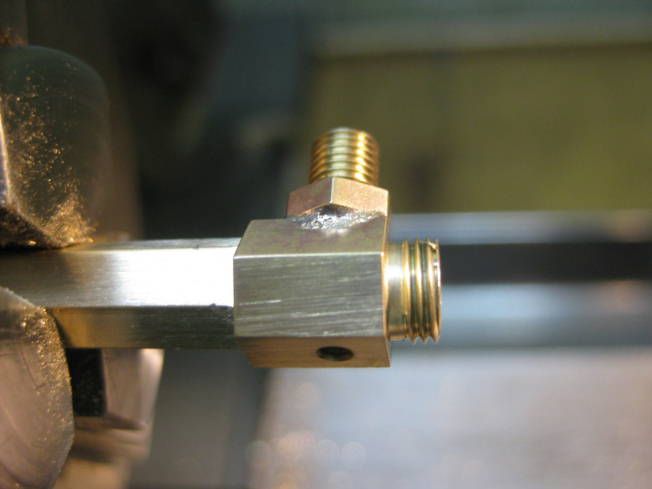

Got on with the first of the top fittings today. Very similar to making the bottom fitting other than starting at its hole end rather than the threaded end. Missing out some of the machining that has been coverd before.

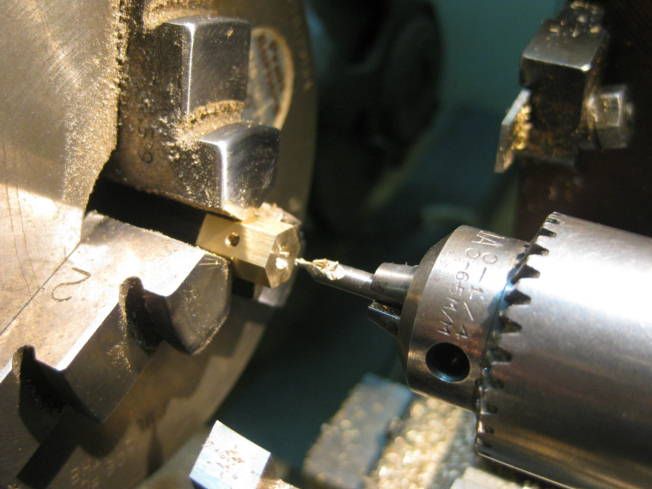

Centre drill.

6.2mm hole 1mm deep for '0' ring seating.

4.8mm hole through to transverse holes for 7/32"x 40 TPI thread.

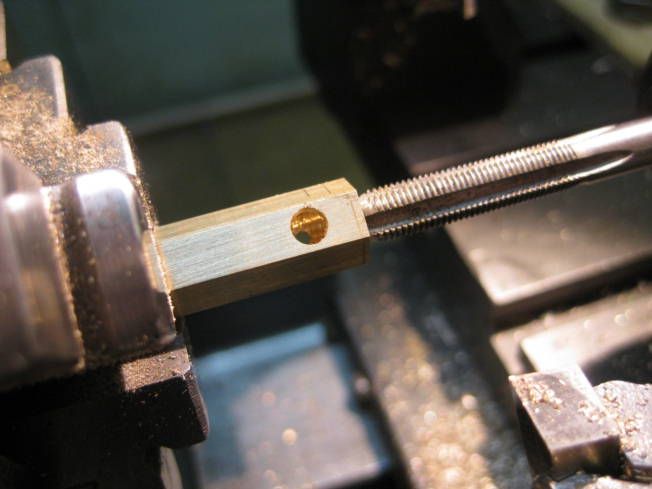

Tapping 7/32" thread.

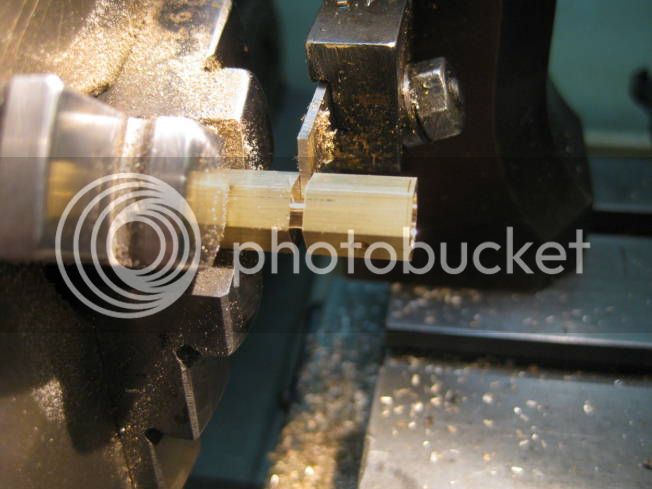

Parting off.

Hole for gauge glass is drilled from this side as it has to be as concentric as possible with the thread.

Centre.

4.2mm hole through for gauge glass shoulder and threaded.

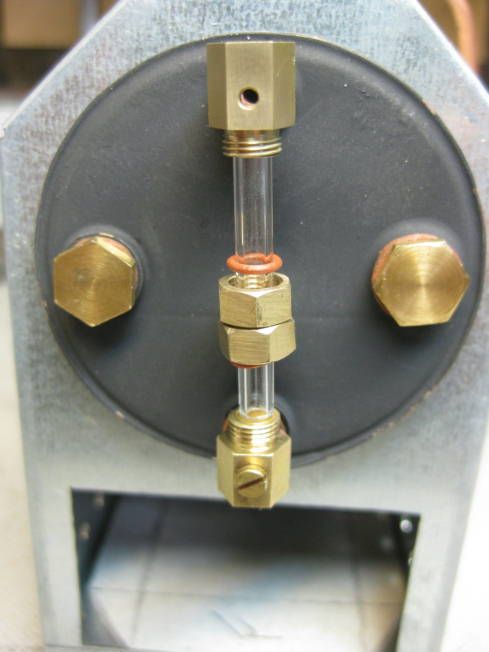

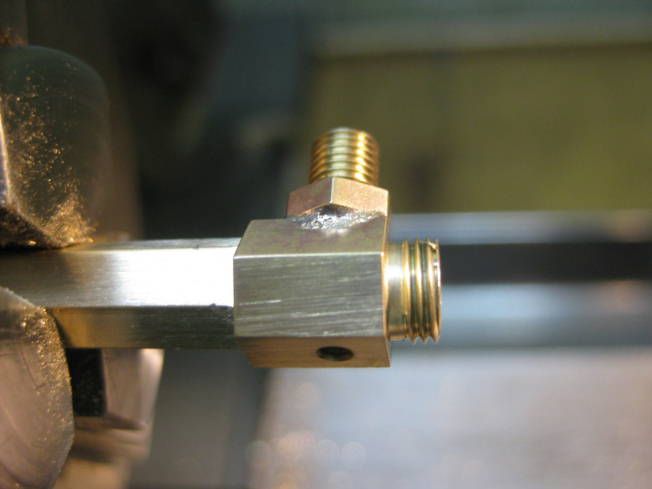

Dry assembly.

Broaching hole for gauge glass and showing over heated joint! Must do better.

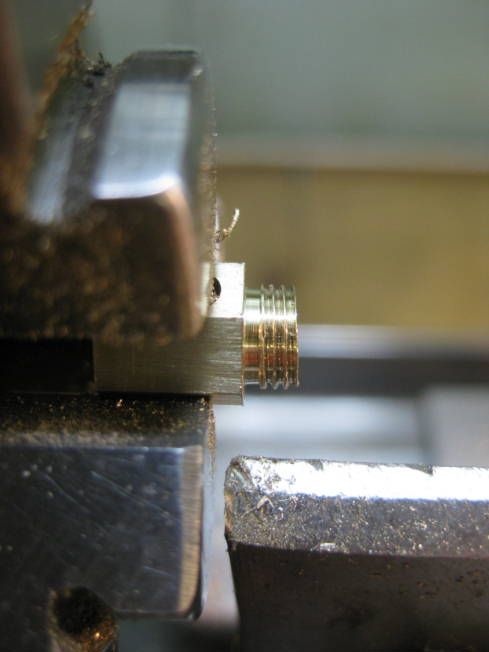

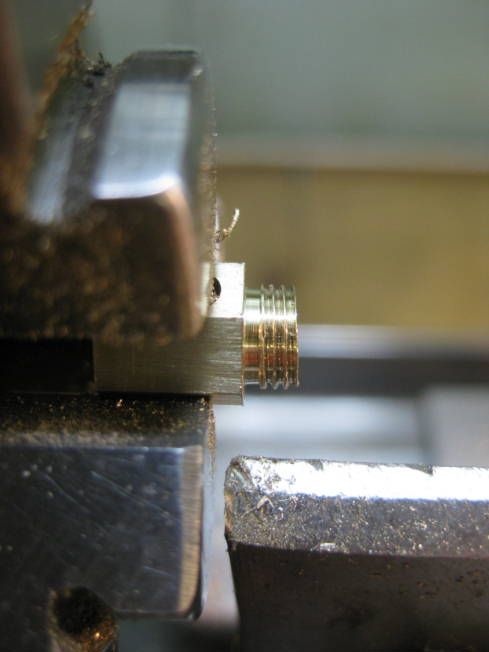

Staring on top nut shouldered and threaded 7/32"x 40 TPI.

Checking fit.

Facing.

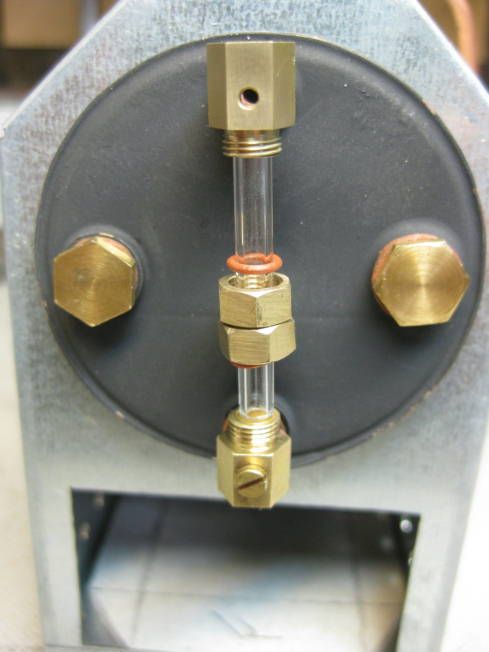

'0' ring fitted.

Assembled next top fitting will have a deeper recess for the '0' ring.

Screws were shortened in the lathe using a file.

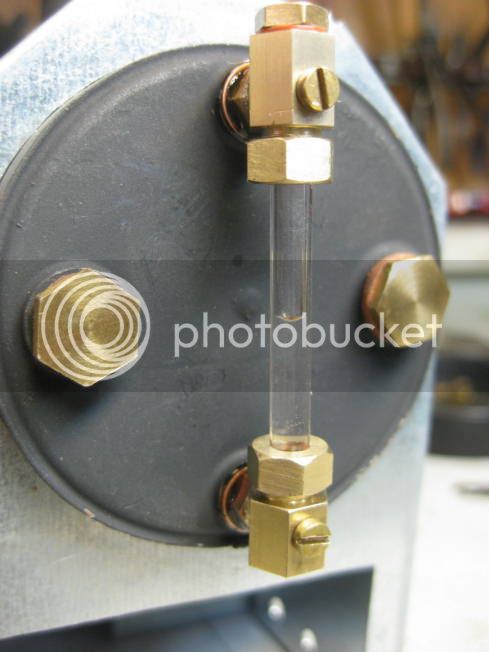

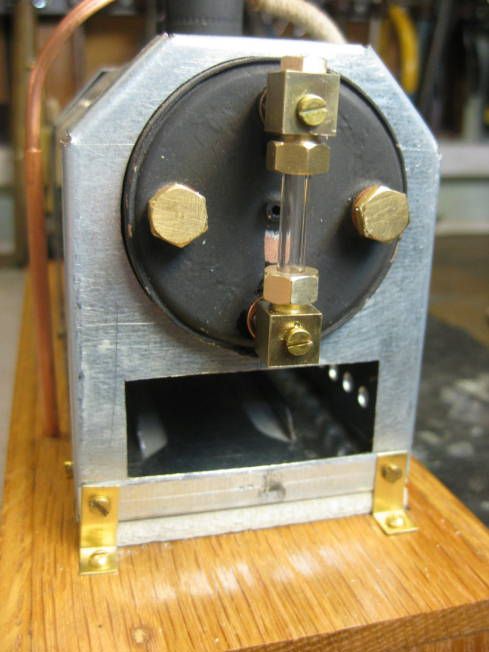

Preliminary assembly of water gauge fittings on the boiler showing copper washers and sealant to be used. Copper distance washers could be used by themselves which was always the way but I think that the sealant reduces to chance of de-zincing.

Fittings sealed being checked using a gauge glass before the sealant goes off.

Fitting glass.

Finished?

Forgot to put the last photograph on PhotoBucket.

I will go and find it.

Regards Tony.

Got on with the first of the top fittings today. Very similar to making the bottom fitting other than starting at its hole end rather than the threaded end. Missing out some of the machining that has been coverd before.

Centre drill.

6.2mm hole 1mm deep for '0' ring seating.

4.8mm hole through to transverse holes for 7/32"x 40 TPI thread.

Tapping 7/32" thread.

Parting off.

Hole for gauge glass is drilled from this side as it has to be as concentric as possible with the thread.

Centre.

4.2mm hole through for gauge glass shoulder and threaded.

Dry assembly.

Broaching hole for gauge glass and showing over heated joint! Must do better.

Staring on top nut shouldered and threaded 7/32"x 40 TPI.

Checking fit.

Facing.

'0' ring fitted.

Assembled next top fitting will have a deeper recess for the '0' ring.

Screws were shortened in the lathe using a file.

Preliminary assembly of water gauge fittings on the boiler showing copper washers and sealant to be used. Copper distance washers could be used by themselves which was always the way but I think that the sealant reduces to chance of de-zincing.

Fittings sealed being checked using a gauge glass before the sealant goes off.

Fitting glass.

Finished?

Forgot to put the last photograph on PhotoBucket.

I will go and find it.

Regards Tony.

Tony Bird

Senior Member

Hi,

I cannot see for looking it was there!

Hi J.Andrew,

I was wondering about one thing I saw in your post. It looks like you were able to hold hex bar in a collet for one of your operations? I didn't know you could do that? What type of collet is that and how many slits on it?

The collet is an ER16 which is gripping the round threaded part of the work piece. Some collets can be used very carefully to hold both square and hexagonal stock. There are collets made that hold shaped stock.

I also like your tangential tool holder. That's on my projects list.

Mine is an Australian made Diamond Tool holder which are made in both RH & LH in several sizes. I am very happy with it and rarely use any other tool

Hi Tom,

I would most interested in you showing us how you do the version with the integral blow down valve - if you can find the time.

I am happy with the way the water gauges have turned out, without too many alterations, I will have to start with the Tipex on the drawings while I still have notes of the alterations. Tomorrow I will finish the other hexagonal fitting and the two square ones. These four fittings were only prototypes before I make a batch, which will probably have square bodies. On previous occasions making water gauges I have made the top fittings completely and left the bottom fittings as parts so if necessary they can be made with blow down valves or with unions to be connected to satellite blow down valves. Using satellite valves can be quite useful for locomotives with enclosed cabs where the water gauge can be seen but no chance of getting fingers to the bottom fitting, they are also good for use on model boats for the same reason. Blow down valves on water gauges are also useful on small boilers for empting them.

After the completing the three water gauges I have a couple of simple boilers that have been hanging around to stick together. I expect the prototype gauges will be used on them. With other jobs on hand it will be several weeks before I start on a batch of water gauges but when I go I will make at least one with a blow down valve and add it to this thread.

Regards Tony.

I cannot see for looking it was there!

Hi J.Andrew,

I was wondering about one thing I saw in your post. It looks like you were able to hold hex bar in a collet for one of your operations? I didn't know you could do that? What type of collet is that and how many slits on it?

The collet is an ER16 which is gripping the round threaded part of the work piece. Some collets can be used very carefully to hold both square and hexagonal stock. There are collets made that hold shaped stock.

I also like your tangential tool holder. That's on my projects list.

Mine is an Australian made Diamond Tool holder which are made in both RH & LH in several sizes. I am very happy with it and rarely use any other tool

Hi Tom,

I would most interested in you showing us how you do the version with the integral blow down valve - if you can find the time.

I am happy with the way the water gauges have turned out, without too many alterations, I will have to start with the Tipex on the drawings while I still have notes of the alterations. Tomorrow I will finish the other hexagonal fitting and the two square ones. These four fittings were only prototypes before I make a batch, which will probably have square bodies. On previous occasions making water gauges I have made the top fittings completely and left the bottom fittings as parts so if necessary they can be made with blow down valves or with unions to be connected to satellite blow down valves. Using satellite valves can be quite useful for locomotives with enclosed cabs where the water gauge can be seen but no chance of getting fingers to the bottom fitting, they are also good for use on model boats for the same reason. Blow down valves on water gauges are also useful on small boilers for empting them.

After the completing the three water gauges I have a couple of simple boilers that have been hanging around to stick together. I expect the prototype gauges will be used on them. With other jobs on hand it will be several weeks before I start on a batch of water gauges but when I go I will make at least one with a blow down valve and add it to this thread.

Regards Tony.

Tony, do you forsee any problems with dezincification of the brass which is in contact with the boiler water? Most commercially made ones and designs for making your own tend to specify bronze or GM and is what I have used on ones I have made in the past along with other boiler fittings such as clacks, blowdowns, plugs, etc.

J

EDIT forget that I missed page two.

J

EDIT forget that I missed page two.

Last edited:

Excellent work, Tony. Thanks for posting all the detailed descriptions and photos. Very helpful, indeed.

Todd

Todd

RonGinger

Well-Known Member

This 'dezincification' is a bit over the top. Has anyone ever seen an actual example of a brass fitting used in a model boiler that exhibited it? I know it is theoretically possible, but I want to hear from a person having seen a real case.

I saw it happen to brass screws on a wood boat once, but the boat was over 40 years old at the time, and of course the screws were under water for about half of each year.

For a model boiler, with infrequent use, and the water only in contact with the end of the screwed parts and the internal passages it seems highly unlikely to ever be a problem.

So, someone have an example to show us?

I saw it happen to brass screws on a wood boat once, but the boat was over 40 years old at the time, and of course the screws were under water for about half of each year.

For a model boiler, with infrequent use, and the water only in contact with the end of the screwed parts and the internal passages it seems highly unlikely to ever be a problem.

So, someone have an example to show us?

Tony Bird

Senior Member

Hi Ron,

This 'dezincification' is a bit over the top. Has anyone ever seen an actual example of a brass fitting used in a model boiler that exhibited it? I know it is theoretically possible, but I want to hear from a person having seen a real case. I saw it happen to brass screws on a wood boat once, but the boat was over 40 years old at the time, and of course the screws were under water for about half of each year. For a model boiler, with infrequent use, and the water only in contact with the end of the screwed parts and the internal passages it seems highly unlikely to ever be a problem.

So, someone have an example to show us?

I have never seen any boiler fittings that I have thought had been effected by dezincification, presumably only the fittings below the water level of the boiler would be effected i.e. bottom water gauge fitting, blow down valve and clacks. I have had fittings break when removing them from boilers that have been used a lot, which I had put down to the fitting being seized, due to mineral (calcium?) forming around the thread. The fittings themselves aren't very strong, a fairly thin wall threaded tube pulling a shoulder against a bush isn't very strong. I haven't seen any visual evidence of thread deterioration on fittings removed from boilers however the type of water used might effect the reaction, I use mostly filtered rainwater (we get a lot in Old South Wales).

I have seen the effect of dezincification in brass model/toy boilers that I have repaired, these boiler shells are often very thin when new and become porous at there bottom where un drained water might lie. The boilers even when cold seem to sweat water before breaking through. I have a failed brass boiler on a locomotive somewhere, I will dig it out and photograph it.

I have had a quick look through The Examination & Testing of Miniature Steam Boilers (Revised Edition 2012).

I cannot find any reference to what boiler fittings should be made from except in Section 13.5 (b) Copper boilers should also be laid up dry to minimise the problem of dezincification of any brass fittings.

Does anyone know of a publication that lists materials that are mandatory for the construction of boiler that the insurance companies will accept?

Regards Tony.

This 'dezincification' is a bit over the top. Has anyone ever seen an actual example of a brass fitting used in a model boiler that exhibited it? I know it is theoretically possible, but I want to hear from a person having seen a real case. I saw it happen to brass screws on a wood boat once, but the boat was over 40 years old at the time, and of course the screws were under water for about half of each year. For a model boiler, with infrequent use, and the water only in contact with the end of the screwed parts and the internal passages it seems highly unlikely to ever be a problem.

So, someone have an example to show us?

I have never seen any boiler fittings that I have thought had been effected by dezincification, presumably only the fittings below the water level of the boiler would be effected i.e. bottom water gauge fitting, blow down valve and clacks. I have had fittings break when removing them from boilers that have been used a lot, which I had put down to the fitting being seized, due to mineral (calcium?) forming around the thread. The fittings themselves aren't very strong, a fairly thin wall threaded tube pulling a shoulder against a bush isn't very strong. I haven't seen any visual evidence of thread deterioration on fittings removed from boilers however the type of water used might effect the reaction, I use mostly filtered rainwater (we get a lot in Old South Wales).

I have seen the effect of dezincification in brass model/toy boilers that I have repaired, these boiler shells are often very thin when new and become porous at there bottom where un drained water might lie. The boilers even when cold seem to sweat water before breaking through. I have a failed brass boiler on a locomotive somewhere, I will dig it out and photograph it.

I have had a quick look through The Examination & Testing of Miniature Steam Boilers (Revised Edition 2012).

I cannot find any reference to what boiler fittings should be made from except in Section 13.5 (b) Copper boilers should also be laid up dry to minimise the problem of dezincification of any brass fittings.

Does anyone know of a publication that lists materials that are mandatory for the construction of boiler that the insurance companies will accept?

Regards Tony.

Tony Bird

Senior Member

Hi,

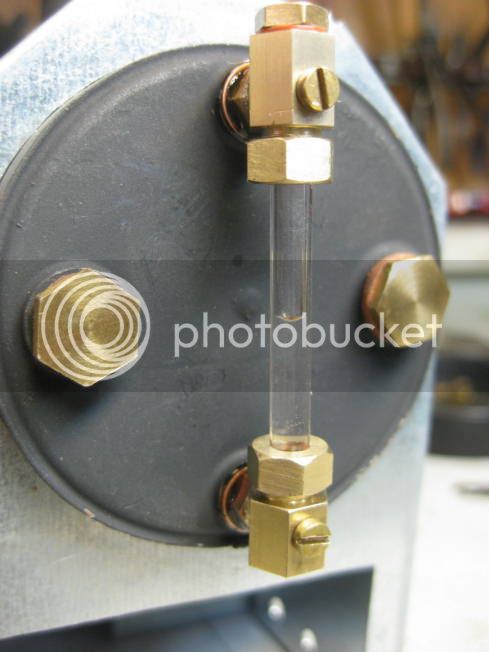

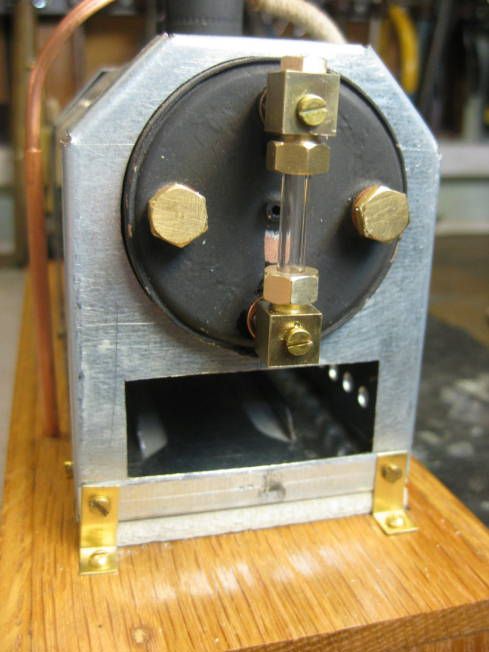

The first of the square body water gauges has been fitted to a boiler.

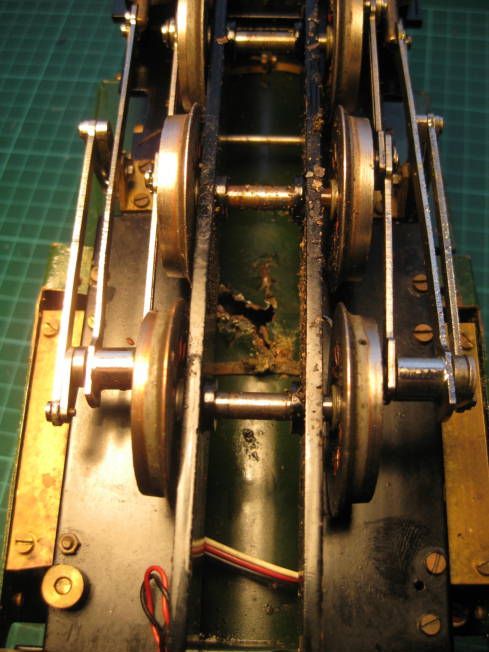

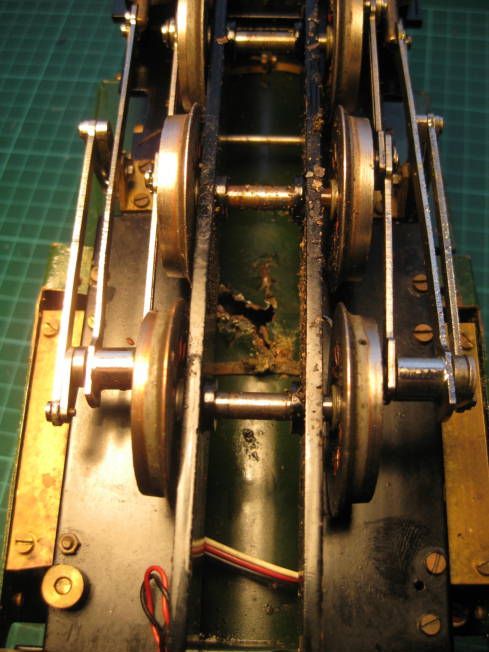

As promised photographs of what I think is de zincing. The locomotive was commercially made in 1984 and was used quite a lot over the next twenty years when the boiler failed, I must get around to making a new copper boiler for it.

Well this is the end of this thread I think.

Regards Tony.

The first of the square body water gauges has been fitted to a boiler.

As promised photographs of what I think is de zincing. The locomotive was commercially made in 1984 and was used quite a lot over the next twenty years when the boiler failed, I must get around to making a new copper boiler for it.

Well this is the end of this thread I think.

Regards Tony.

modeng2000

Well-Known Member

- Joined

- Nov 14, 2008

- Messages

- 146

- Reaction score

- 37

Well Tony, I just wanted to say how much your information has been helpful to me - A LOT - thanks.

Your boiler build is a valuable reference for anyone making a boiler. It occurred to me that you might put both the boiler build and the fittings together as say a PDF file for folks to download and keep. Easy to say but I don't know how much work is involved.

John

Your boiler build is a valuable reference for anyone making a boiler. It occurred to me that you might put both the boiler build and the fittings together as say a PDF file for folks to download and keep. Easy to say but I don't know how much work is involved.

John

Tony Bird

Senior Member

Hi John,

Glad you enjoyed it. Alas my computer skills are not up to what you suggest. If anyone would like to do it, please do.

Regards Tony.

Glad you enjoyed it. Alas my computer skills are not up to what you suggest. If anyone would like to do it, please do.

Regards Tony.

Gedeon Spilett

Well-Known Member

An advice that was given to me recently (ie not yet tested) is to put a small copper wire into the gauge glass, to limit the blocking by air bubbles while filling the boiler.

Too sad for this little loco...hey, only one boiler is required, you do not have to do a batch!

Too sad for this little loco...hey, only one boiler is required, you do not have to do a batch!

Tony Bird

Senior Member

Hi Gedeon,

An advice that was given to me recently (ie not yet tested) is to put a small copper wire into the gauge glass, to limit the blocking by air bubbles while filling the boiler.

I also have heard but never tried this, I have two small boat boilers to build so will try it on one of them and report results

Too sad for this little loco...hey, only one boiler is required, you do not have to do a batch!

The model locomotive is a Merlin/Beck with obviously a brass boiler which has a non standard OD. Also the regulator/lubricator is in its steam dome which is odd. I will have another look at it, you are quite right I should do something about it, but so many other jobs!

Regards Tony.

An advice that was given to me recently (ie not yet tested) is to put a small copper wire into the gauge glass, to limit the blocking by air bubbles while filling the boiler.

I also have heard but never tried this, I have two small boat boilers to build so will try it on one of them and report results

Too sad for this little loco...hey, only one boiler is required, you do not have to do a batch!

The model locomotive is a Merlin/Beck with obviously a brass boiler which has a non standard OD. Also the regulator/lubricator is in its steam dome which is odd. I will have another look at it, you are quite right I should do something about it, but so many other jobs!

Regards Tony.

KBC

Junior Member

- Joined

- Feb 22, 2012

- Messages

- 80

- Reaction score

- 53

Does anyone know of a publication that lists materials that are mandatory for the construction of boiler that the insurance companies will accept?

Regards Tony.

Hi Tony,

Further to your question on boiler materials, I can only assume that the insurance companies rely on the Model Engineering Societies ability to test boilers but as to what materials the Companies will accept is unknown.

It would appear that the only publication stating boiler materials and Calc's for designs is K.N.Harris's book MODEL BOILERS & BOILERMAKING

Copper for the shell is the preferred material and and easier for the amateur to work with .

Phos Bronze or Gun metal for boiler bushes, brass is frowned upon as the high temps required to melt silver solder can destroy the thread in the brass and can cause failure to the fittings.

Boiler stays to be Monel metal or Phos bronze, brass stays are not mentioned but I suppose it's the same problem with the threads being weakened by the heat and eventual corrosion.

I can only assume that as you are an experienced builder that you have a copy of the above mentioned book, if not I would recommend that you get one.

The fitting of a copper rod into the sight glass does stop bubbles forming it breaks the surface tension of the bubble allowing a true reading, modelers use the copper wire stripped from electrical cable.

I hope this helps, not a definitive answer but like you I have never been able to find out how the Insurance companies set what materials must be used and the Regs are more to do with Loco boilers with Marine boilers as an after thought.

George.

Regards Tony.

Hi Tony,

Further to your question on boiler materials, I can only assume that the insurance companies rely on the Model Engineering Societies ability to test boilers but as to what materials the Companies will accept is unknown.

It would appear that the only publication stating boiler materials and Calc's for designs is K.N.Harris's book MODEL BOILERS & BOILERMAKING

Copper for the shell is the preferred material and and easier for the amateur to work with .

Phos Bronze or Gun metal for boiler bushes, brass is frowned upon as the high temps required to melt silver solder can destroy the thread in the brass and can cause failure to the fittings.

Boiler stays to be Monel metal or Phos bronze, brass stays are not mentioned but I suppose it's the same problem with the threads being weakened by the heat and eventual corrosion.

I can only assume that as you are an experienced builder that you have a copy of the above mentioned book, if not I would recommend that you get one.

The fitting of a copper rod into the sight glass does stop bubbles forming it breaks the surface tension of the bubble allowing a true reading, modelers use the copper wire stripped from electrical cable.

I hope this helps, not a definitive answer but like you I have never been able to find out how the Insurance companies set what materials must be used and the Regs are more to do with Loco boilers with Marine boilers as an after thought.

George.

Tony Bird

Senior Member

Hi George,

I can only assume that as you are an experienced builder that you have a copy of the above mentioned book, if not I would recommend that you get one.

I have made a few boiler of different types and sizes all to the spec's suggested in both K.N.H. and Martin Evans books. Most of the removable fittings have been made from brass, I make most fittings but always assumed the ones bought were also made from brass, apparently not?

I think I will continue to use brass until I know bronze and monometal become mandatory.

Regards Tony.

I can only assume that as you are an experienced builder that you have a copy of the above mentioned book, if not I would recommend that you get one.

I have made a few boiler of different types and sizes all to the spec's suggested in both K.N.H. and Martin Evans books. Most of the removable fittings have been made from brass, I make most fittings but always assumed the ones bought were also made from brass, apparently not?

I think I will continue to use brass until I know bronze and monometal become mandatory.

Regards Tony.

KBC

Junior Member

- Joined

- Feb 22, 2012

- Messages

- 80

- Reaction score

- 53

Hi George,

I can only assume that as you are an experienced builder that you have a copy of the above mentioned book, if not I would recommend that you get one.

I have made a few boiler of different types and sizes all to the spec's suggested in both K.N.H. and Martin Evans books. Most of the removable fittings have been made from brass, I make most fittings but always assumed the ones bought were also made from brass, apparently not?

I think I will continue to use brass until I know bronze and monometal become mandatory.

Regards Tony.

Hi Tony,

I don't think that any other metal other than brass will be made mandatory for fittings.

Over the years that I have been making boilers and fittings there has never been any other metal with the sections that can be had with brass, for instance Phos bronze and Monel are not available in the Hex range that can be had in brass, plus the cost would be prohibitive if they were available and I don't know of a supplier who makes fittings other than in brass.

Like you I make all of my own fittings from brass and will continue to do so.

George.

Niceonetidy

Colin D

- Joined

- Jul 20, 2012

- Messages

- 121

- Reaction score

- 35

Hi Tony,

I don't think that any other metal other than brass will be made mandatory for fittings.

Over the years that I have been making boilers and fittings there has never been any other metal with the sections that can be had with brass, for instance Phos bronze and Monel are not available in the Hex range that can be had in brass, plus the cost would be prohibitive if they were available and I don't know of a supplier who makes fittings other than in brass.

Like you I make all of my own fittings from brass and will continue to do so.

George.

Smith metals sell phosphor bronze hexagon bar, and short pieces too

Tony, This may be an old thread, but a really "good 'un". Many items covered that confirmed I do a sensible job making my water gauges. (But I cheat and use proprietary nuts!). I like your graving, I haven't come across anyone else doing this, but my Grandfather taught me when I was a boy, so I use it as a quick way to do odd bits - just as you do.

And all your little tricks - like a wire in the tailstock chuck to catch the part being parted-off... I use regularly.

Also I use the same tool bit holder as you, (Home made).

On de-zincification. I had a brass screw in the bottom (drain point) for the bottom fitting - that obviously didn't naturally drain when the boiler was blown-down. After at least 10 years of use, it leaked then simply crumbled when I did the annual fill and hydraulic test. Cleaned it out with a cocktail stick and pipe cleaner! But the gauge fittings in Brass are still OK 15 years later. So may be just the screw material was not as good? (More ZInc?).

Thanks for the excellent thread.

K2

And all your little tricks - like a wire in the tailstock chuck to catch the part being parted-off... I use regularly.

Also I use the same tool bit holder as you, (Home made).

On de-zincification. I had a brass screw in the bottom (drain point) for the bottom fitting - that obviously didn't naturally drain when the boiler was blown-down. After at least 10 years of use, it leaked then simply crumbled when I did the annual fill and hydraulic test. Cleaned it out with a cocktail stick and pipe cleaner! But the gauge fittings in Brass are still OK 15 years later. So may be just the screw material was not as good? (More ZInc?).

Thanks for the excellent thread.

K2

Johan Maritz

Active Member

Very good write up and a very needed one for me. I have been studying literature and drawings for weeks now on how to make these fittings. This comes at a most welcome time. Thanks Tony, very good tips there as well, experience shows.

Mr Tony Bird,

I have been meaning to make various gauge glasses for a few of my locos / projects I am working on, and had been putting them off for a while. Finding decent and accurate drawings or details was quite tricky. I had dome some drawings myself, but not taken the plunge to actually fabricate any as yet. Your post has spurred me on, and I will try and do some this weekend! So thank you.

I will be videoing my progress and will post a video in the near future. (Depending on how successful I am! ha)

Thankyou again for your very detailed post. I may return with some questions if that is ok!

Kindest Regards,

Del

I have been meaning to make various gauge glasses for a few of my locos / projects I am working on, and had been putting them off for a while. Finding decent and accurate drawings or details was quite tricky. I had dome some drawings myself, but not taken the plunge to actually fabricate any as yet. Your post has spurred me on, and I will try and do some this weekend! So thank you.

I will be videoing my progress and will post a video in the near future. (Depending on how successful I am! ha)

Thankyou again for your very detailed post. I may return with some questions if that is ok!

Kindest Regards,

Del

ajoeiam

Well-Known Member

Speaking only for myself - - - - please offer your results in written form with pictures.Mr Tony Bird,

I have been meaning to make various gauge glasses for a few of my locos / projects I am working on, and had been putting them off for a while. Finding decent and accurate drawings or details was quite tricky. I had dome some drawings myself, but not taken the plunge to actually fabricate any as yet. Your post has spurred me on, and I will try and do some this weekend! So thank you.

I will be videoing my progress and will post a video in the near future. (Depending on how successful I am! ha)

snip

I find videos problematic for a number of reasons

1. storage space

2. plethora of poorly compatible formats

3. huge amount of time to view

4. tough to do well

Please - - - its one vote for a write up w photos.

TIA

Similar threads

- Replies

- 0

- Views

- 732

- Replies

- 1

- Views

- 710