You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Walking Beam Conveyor

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

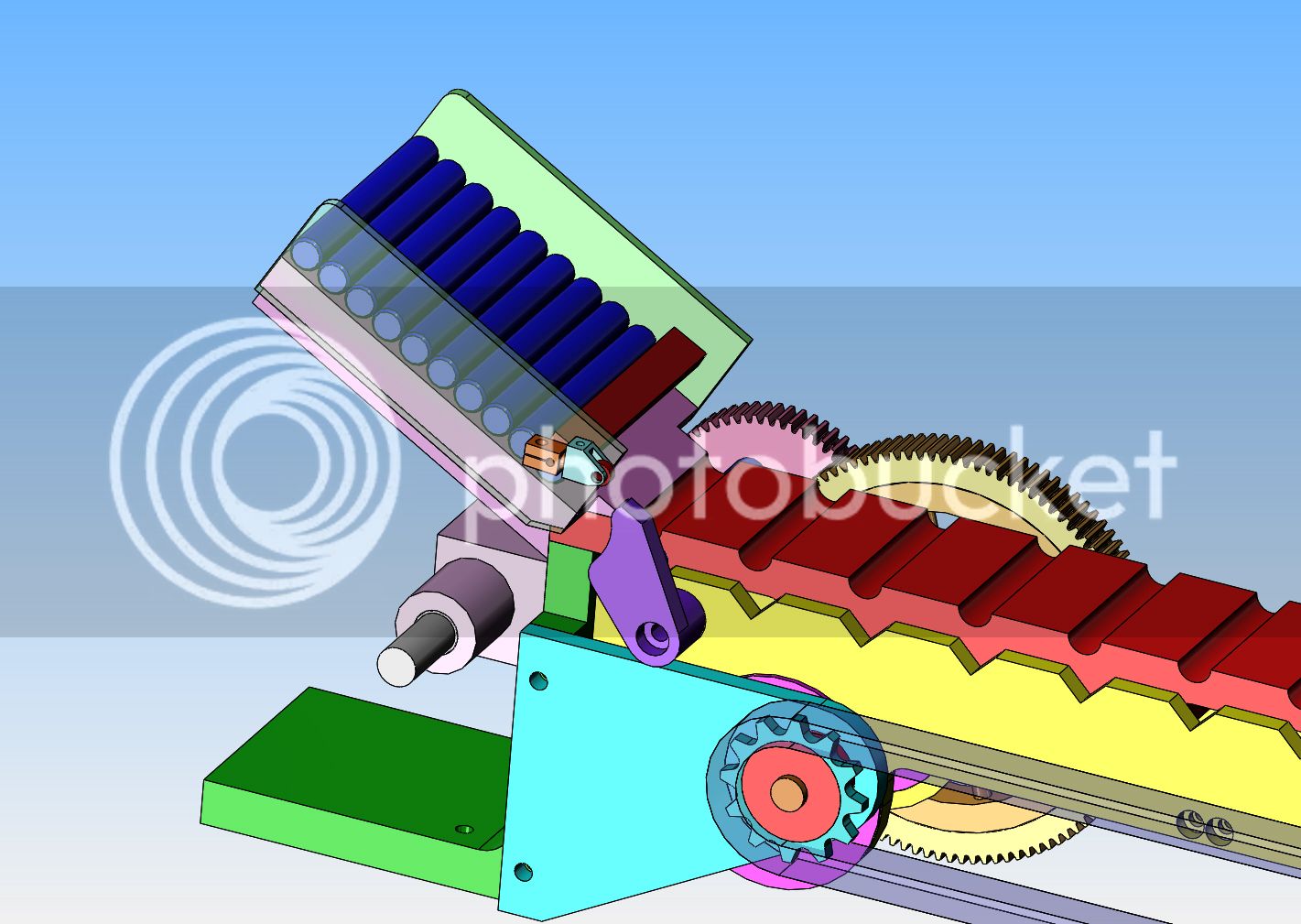

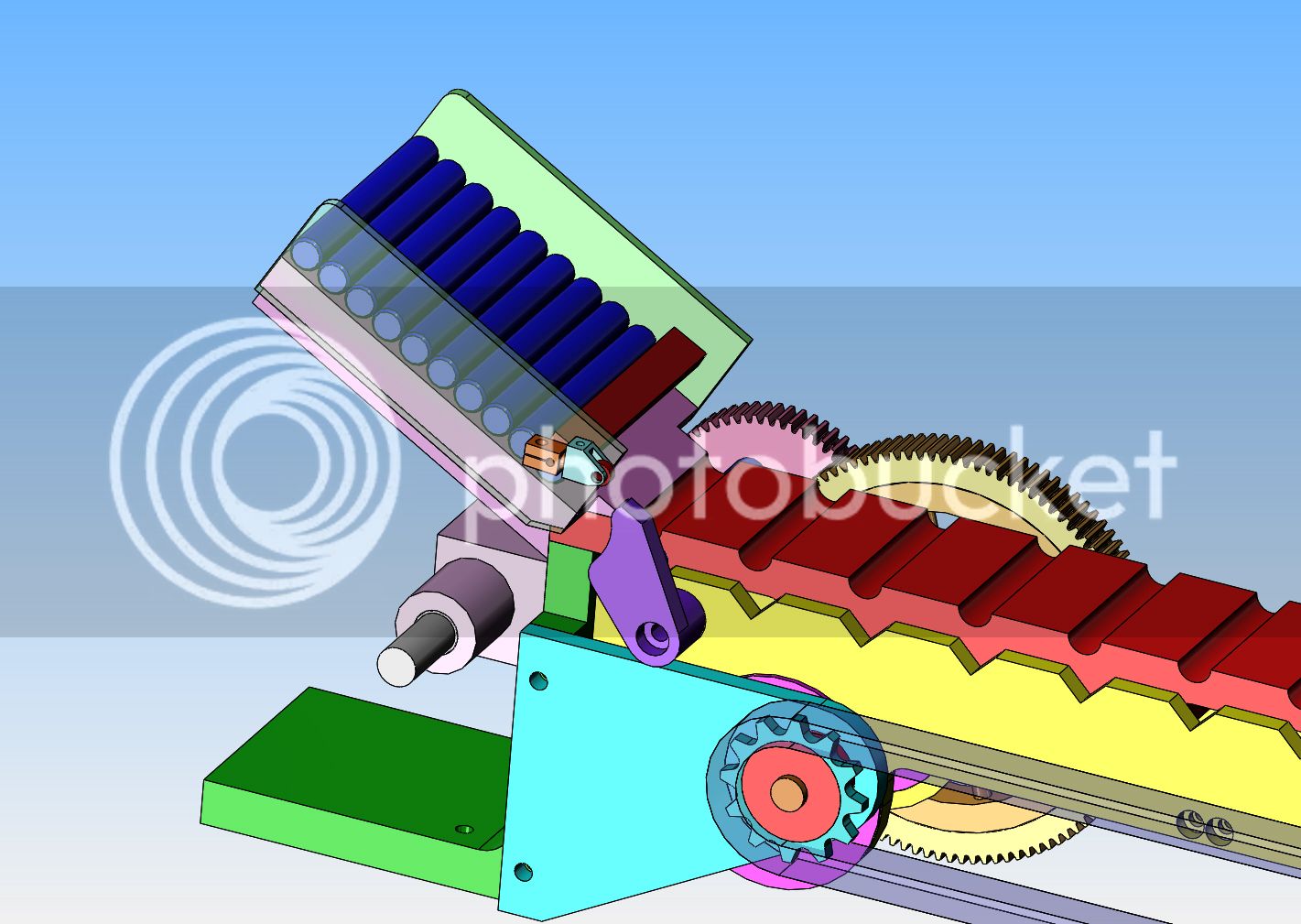

Installing the second set of gears has made a remarkable difference in the operation of the walking beam. There are two major benefits from this. The beam operates 3 times slower than it did before, and is 3 times easier to turn. With only the first set of gears, it was so stiff that I feared that one of my little engines wouldn't be able to run it. Now it is quite easy to turn by hand. I will probably post a video of it being driven by one of my small engines, and then my next phase will be to design and build a "load magazine" and an escapement mechanism to load material onto the end of the walking beam.

This video shows the walking beam running at a more sedate pace, with the added set of gears on it, powered by hand.

[ame]https://www.youtube.com/watch?v=ASnkO08sT5Y&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=ASnkO08sT5Y&feature=youtu.be[/ame]

No real work tomorrow and no "at home" machining lined up either. Good wife is off to Orangeville to babysit a grandson. So--I think I will work on the design of a "magazine" feeder which I can load up with 3/8" diameter x 3 1/2" steel "blanks" to feed the walking beam. The magazine itself presents no challenges. The trick will be in the escapement mechanism which will dispense one part at a time onto the walking beam at the correct time. The escapement will have to be triggered by the movement of the walking beam as it cycles, and it will have to be totally mechanical in nature.

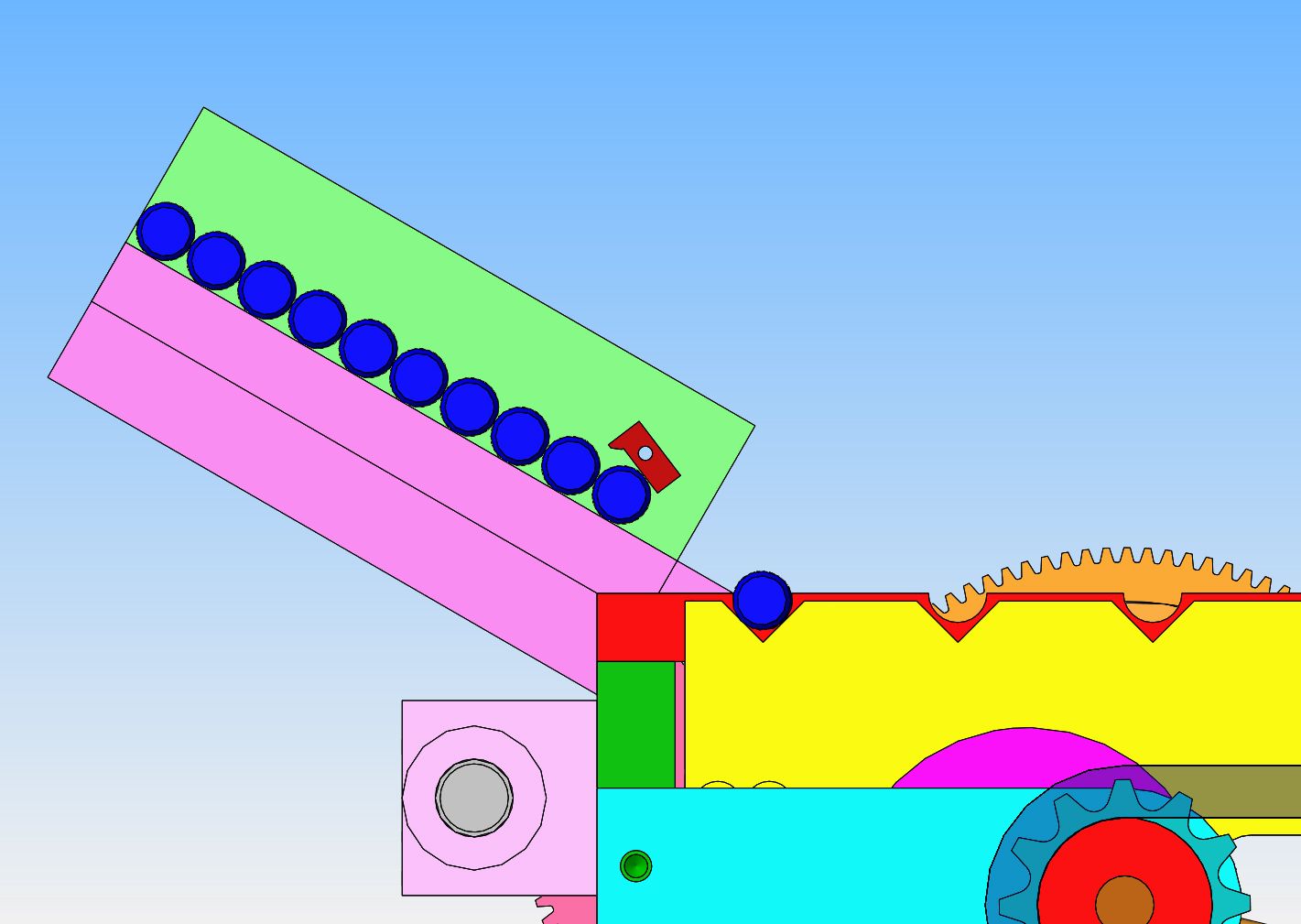

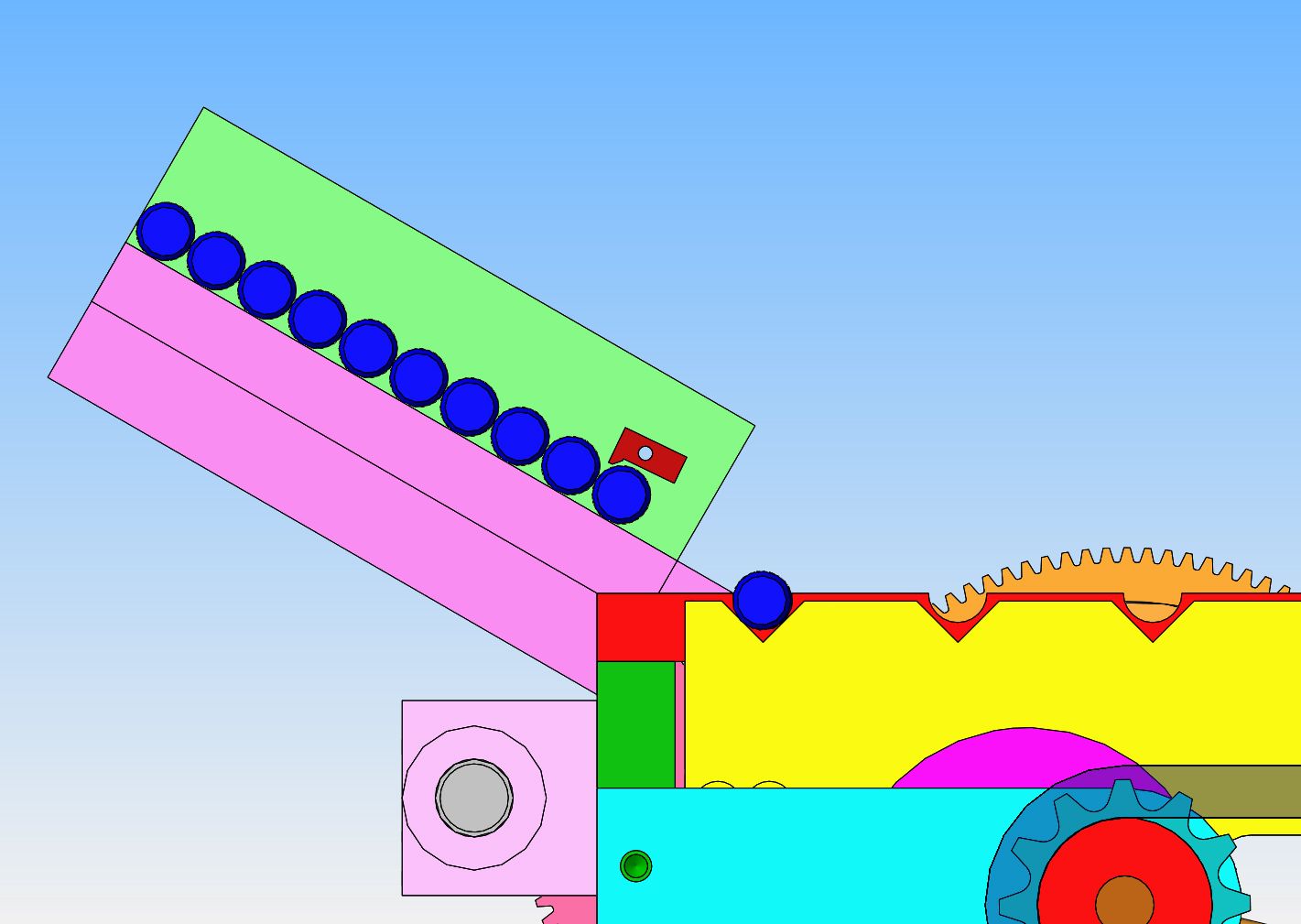

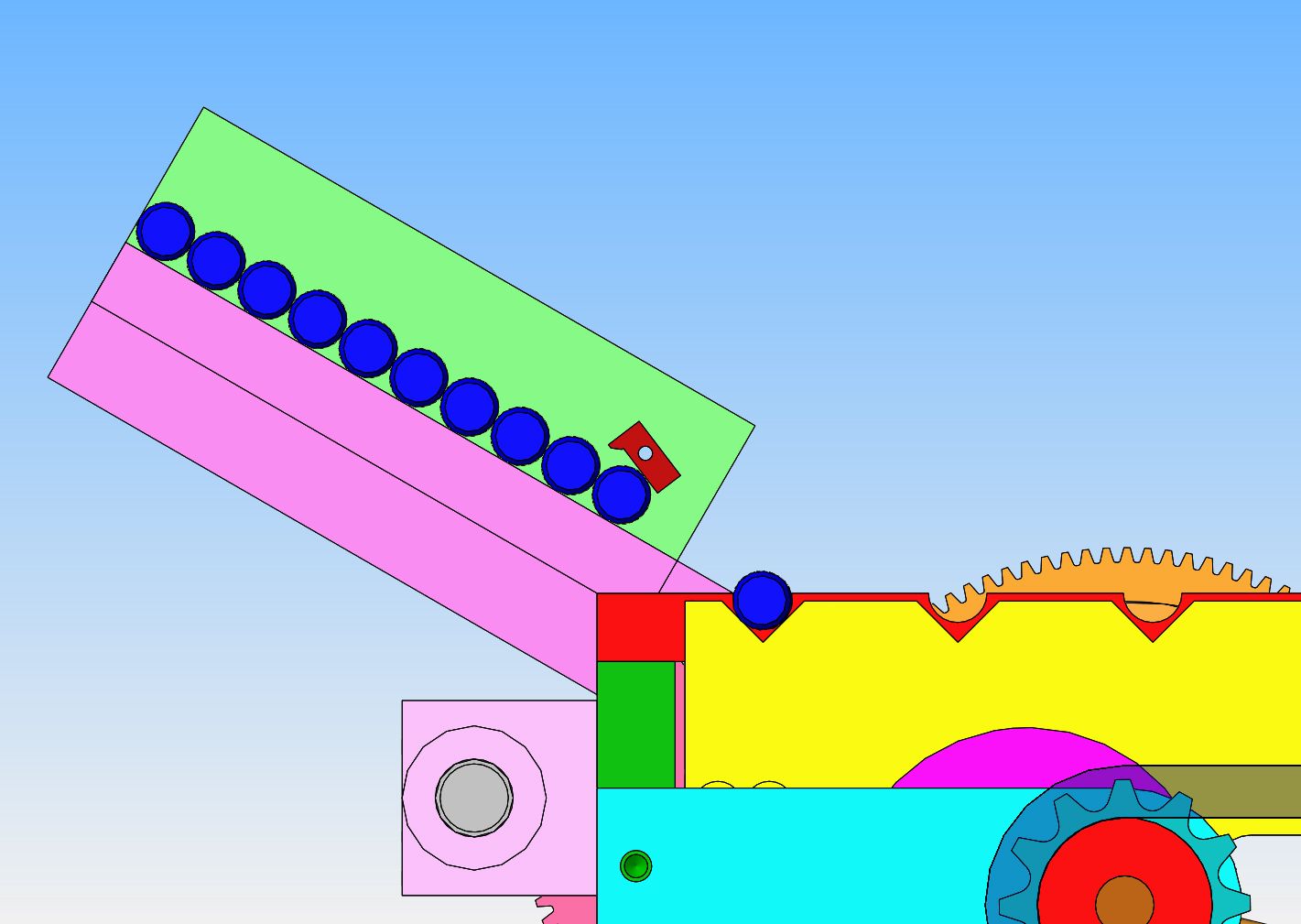

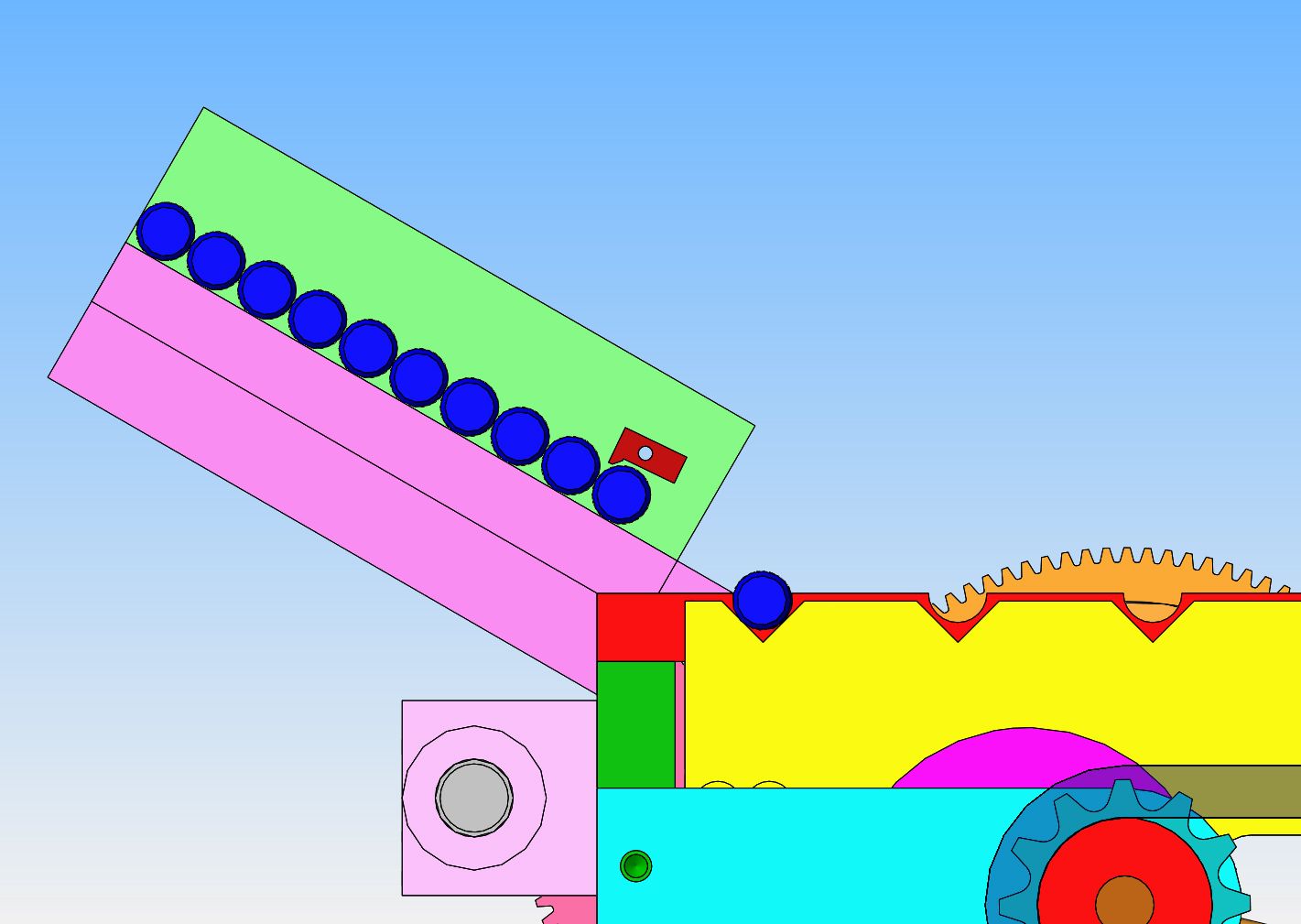

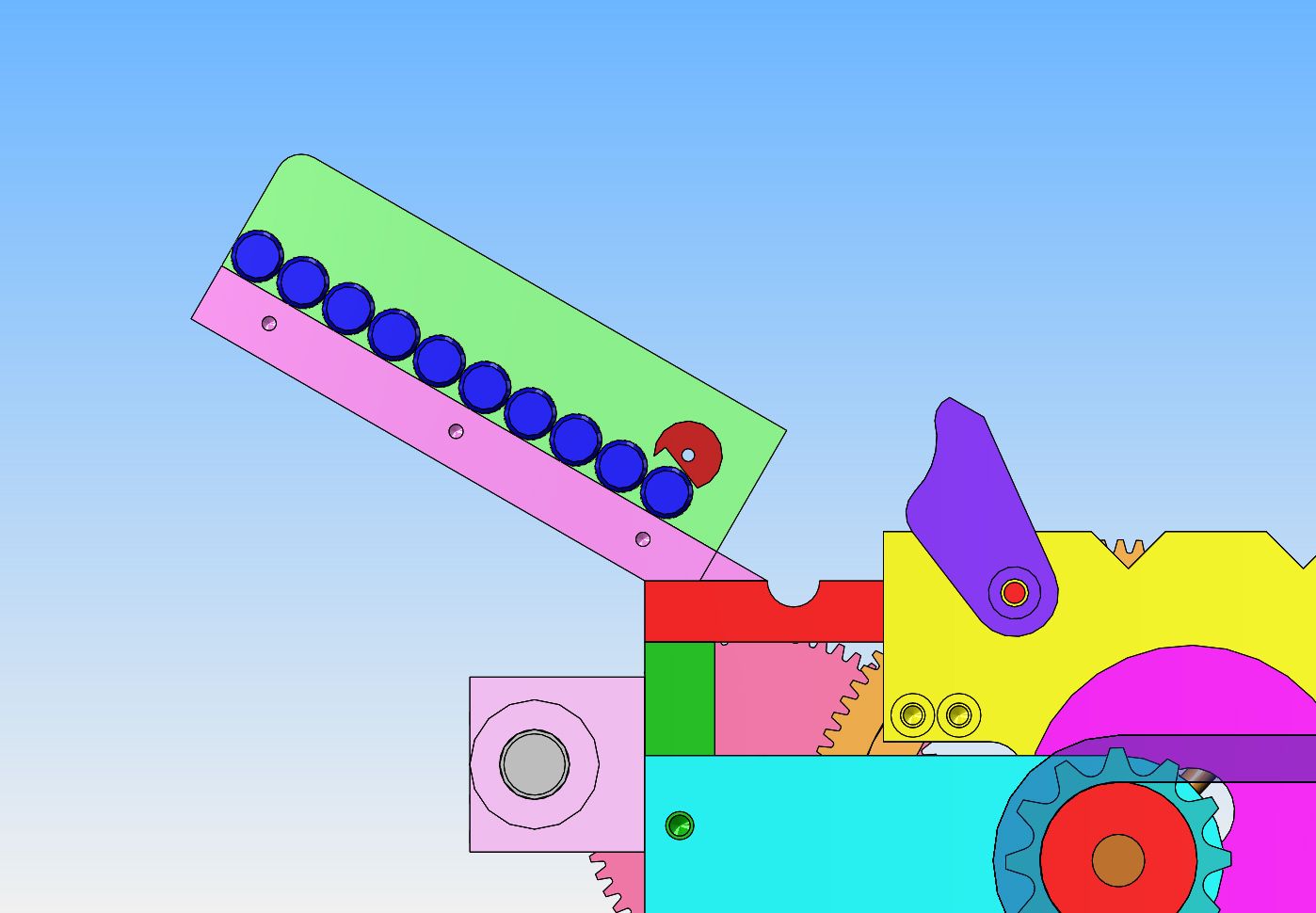

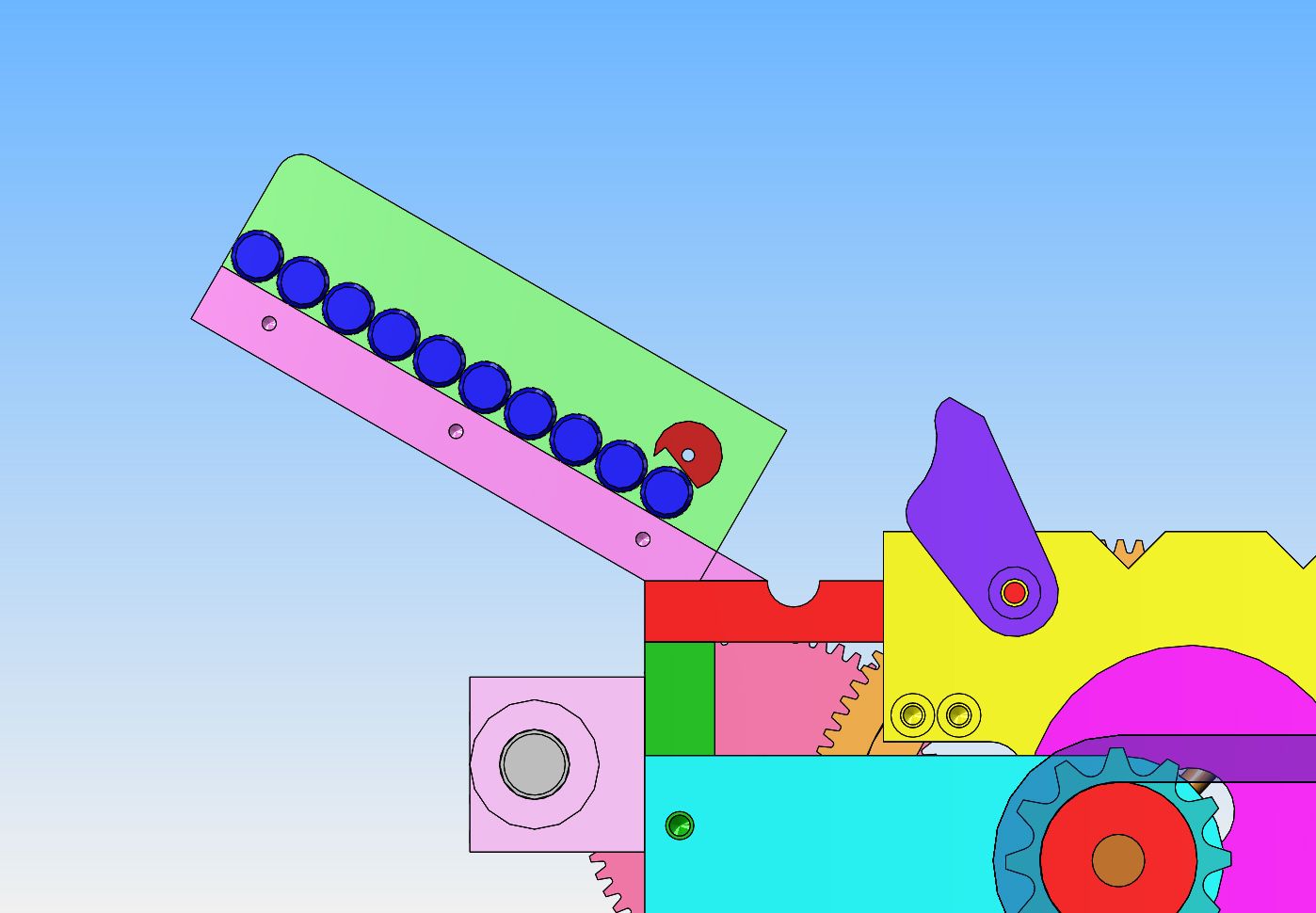

This shows the load magazine with 10 parts in it. There is a little red pivoting rocker in the magazine, and in the first drawing it is in a position to block all of the parts in the magazine from rolling down into the walking beam. In the second picture, it is rotated into position to release one part to roll down onto the walking beam, but block all the other parts and prevent them from rolling down the ramp. this rocker rocks back and forth to release one part at a time to the walking beam.

So here we have it---Full on, rock and roll, old style mechanical automation!! There is a small lever with a ball bearing (in red) on the end of it and that lever is attached to the pivot shaft on the red pivoting rocker. The purple cam is bolted solidly to the side of the walking beam. You don't see it here, but there is a tension spring on the far end of that red pivoting rocker which holds the pivoting rocker in the position which does not allow any of the parts to roll down the ramp onto the walking beam. As the walking beam comes around, that purple cam hits the red bearing and swings the lever just enough to swing the pivoting rocker to let one "part" escape and roll down the ramp into the first trough in the stationary center section of the walking beam. It is only a very brief contact, and then the cam is past the bearing and the spring pulls the pivoting rocker back into the "stop" position to prevent any more parts rolling down the ramp until the walking beam comes around again.

Can anybody see the videos I have posted in this thread? All I am seeing now is a black rectangle. It's not at my end, because the two other forums I post on show the videos with no problem.---Brian

Thank you mark. This walking beam is very interesting, and it certainly is something different. I'm not getting many responses to this thread, so I guess most people don't find it very interesting. I will probably finish it, or at least get very close to finishing it today.----Brian

stragenmitsuko

Well-Known Member

- Joined

- Jan 19, 2016

- Messages

- 326

- Reaction score

- 143

I think its a great little project .

And I can see the video , no worries there

Pat

And I can see the video , no worries there

Pat

Photobucket is down right now

Cogsy

Well-Known Member

I'm following along Brian, just keeping quiet for a change...

- Joined

- Jan 24, 2009

- Messages

- 554

- Reaction score

- 123

I'm following along Brian, just keeping quiet for a change...

Me too! Don't give up just 'cause some of us are quiet. We're still reading. But then how would you know that???

Pete

Hey!!--I feel just like Steve Earl in Copperhead Road. I woke up with a brand new plan.--and it works fabulously. I just made a new escapement rocker, and it does the job quite nicely, to dispense one "part" at a time while holding the other parts back in the magazine. My first escapement rocker would release a part okay, but the next part uphill from it would roll under the uphill side of the rocker and jam it. My new design has a round lip on the uphill side to prevent that happening. I have built it and tried it out already, and what I've done will not be visible in photographs, but this is what the new Improved escapement rocker looks like.

So---There we have it. I'm pleased as can be!! The walking beam and the automatic feeder work just as I had hoped. I guess all that is left is a video of it being driven by one of my engines.

[ame]https://www.youtube.com/watch?v=jCyr3SeLI2k&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=jCyr3SeLI2k&feature=youtu.be[/ame]

I would call this a complete success This is the final video, showing the walking beam being driven by my vertical I.C. engine.

[ame]https://www.youtube.com/watch?v=_2uPyXMaA4o&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=_2uPyXMaA4o&feature=youtu.be[/ame]

Similar threads

- Replies

- 77

- Views

- 24K

- Replies

- 86

- Views

- 21K