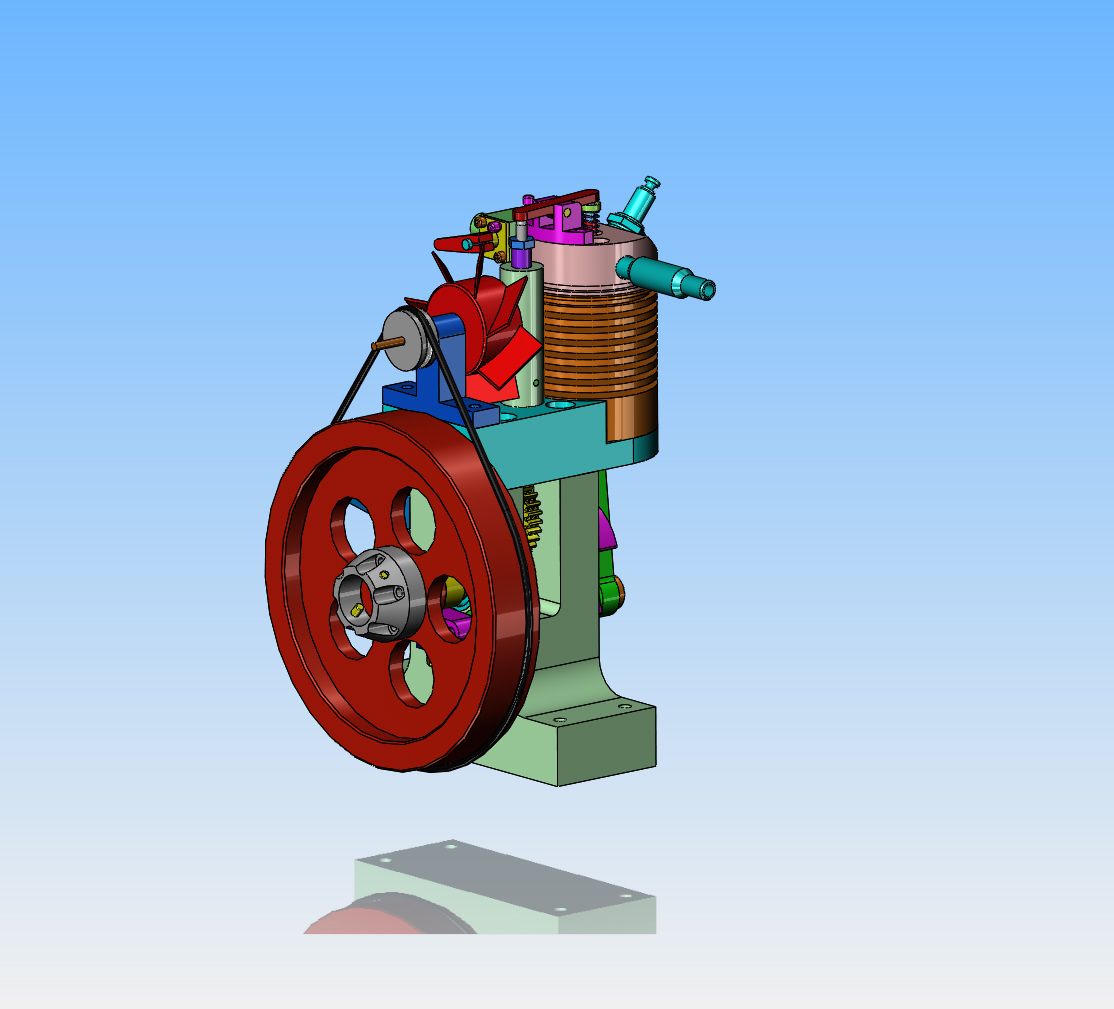

I'm still making some progress. So far I have the flywheel, crank web and big end, con-rod, con-rod retainer, rocker arm and exhaust pipe completed. Plus half the carby. Still got a long way to go and my available shop time is about to dry up. Hoping to average a completed part per week until it's all done.

I found a tiny error on the carby body plans - the throttle stop screw hole is dimensioned as .294 deep, but then threaded 4-40 .394 deep. I have to ask - what does JAG stand for?

The throttle stop hole breaks thru into the center hole that the throttle barrel fits into. You have to run your tap in at least 0394" to get past the taper on the tap.--Actually I just made that up!! The thread call outs are all an automatic function of the software. Occasionally they do something weird like that. Thank you for the update.--Brian