Hi folks,

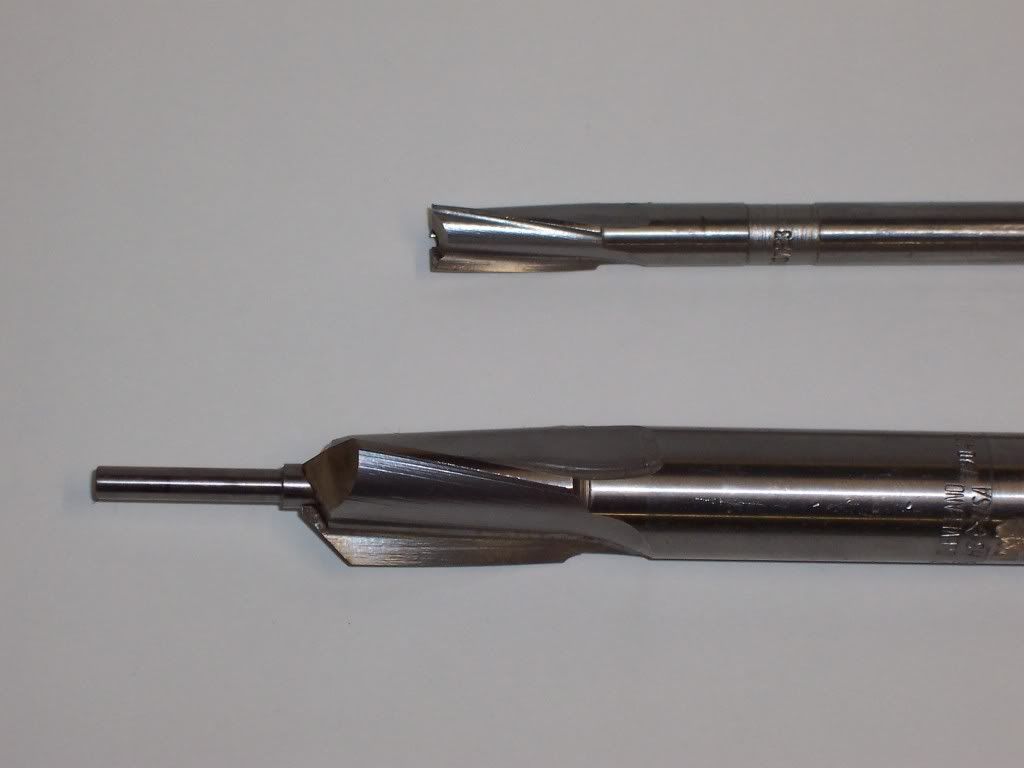

I thought you might like to see how I overcame the dreaded leaky valve seat problem. It always seemed like I was struggling

with getting my valves to seal on my IC engines. I decided to make a valve seat cutter by using a piloted counterbore, the kind with removable pilots. The cutting edge was ground on an OD grinder using a dummy pilot

with a center drilled into the end to be able to place it between centers. The cutting edge was ground to 45 degrees and then relieved by hand using a grinding wheel. Final sharpening was done by hand using an india stone. For the most part

my valves now seal with no or very little lapping. If you attempt to make a cutter like this, it could be done on the lathe

using a tool post grinder, but be careful. When cutting seats, the cutter shouldn't be run very fast and shouldn't be allowed to dwell too

long at the bottom of the cut. I normally only cut my seats to .010 -.015 width. The cutter can be used on different

size seats and by using removable pilots it can be used on different valve guide diameters. I hope this will help you with your

projects. Bye for now , and remember to work safely. Dave

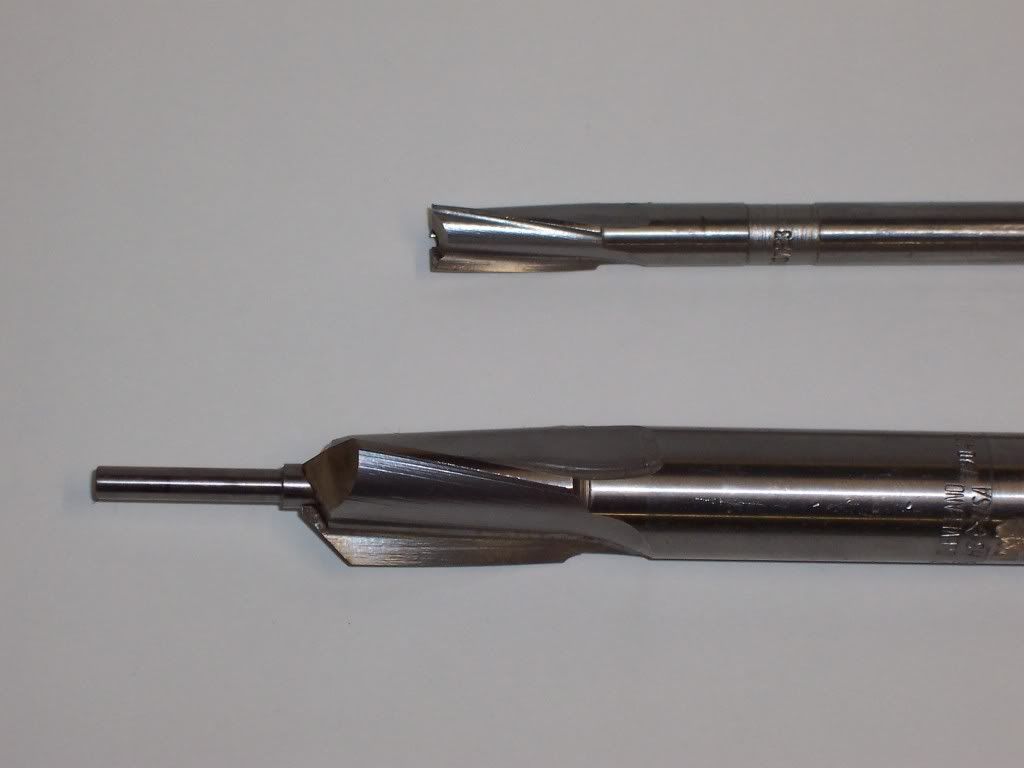

I thought you might like to see how I overcame the dreaded leaky valve seat problem. It always seemed like I was struggling

with getting my valves to seal on my IC engines. I decided to make a valve seat cutter by using a piloted counterbore, the kind with removable pilots. The cutting edge was ground on an OD grinder using a dummy pilot

with a center drilled into the end to be able to place it between centers. The cutting edge was ground to 45 degrees and then relieved by hand using a grinding wheel. Final sharpening was done by hand using an india stone. For the most part

my valves now seal with no or very little lapping. If you attempt to make a cutter like this, it could be done on the lathe

using a tool post grinder, but be careful. When cutting seats, the cutter shouldn't be run very fast and shouldn't be allowed to dwell too

long at the bottom of the cut. I normally only cut my seats to .010 -.015 width. The cutter can be used on different

size seats and by using removable pilots it can be used on different valve guide diameters. I hope this will help you with your

projects. Bye for now , and remember to work safely. Dave