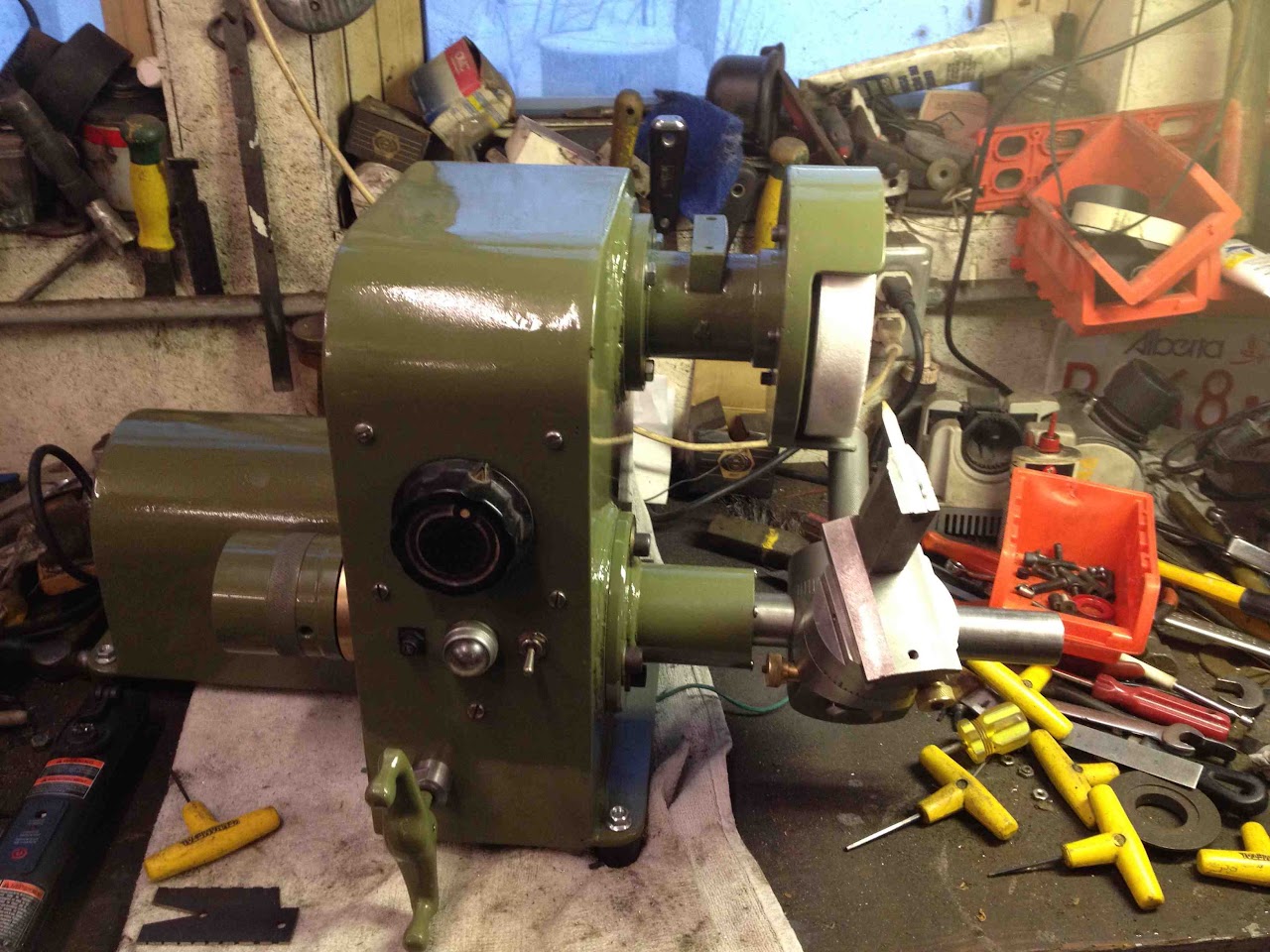

The spindle was salvaged from a very old ice skate sharpener. Thought it would save some fabricating, would have been easier to start from scratch. It originally had tapered roller bearings, which cleaned up and looked good but ran horribly rough. Ended up a 6203 ball bearing was a direct fit replacement. I shrunk a flange on the spindle, then machined the assembly to mount the wheels.

The end thread allows me to use 1 1/4 bore cup wheels and the large flange works for bolt on metal backed wheels and diamond surfaced ones.

It uses a dc motor salvaged from a tread mill with a small serpentine type belt drive to the spindle. The dc motor powered by an old school variable transformer gives me 3400 rpm for the aluminum oxide wheels and 5400 for the diamond ones.

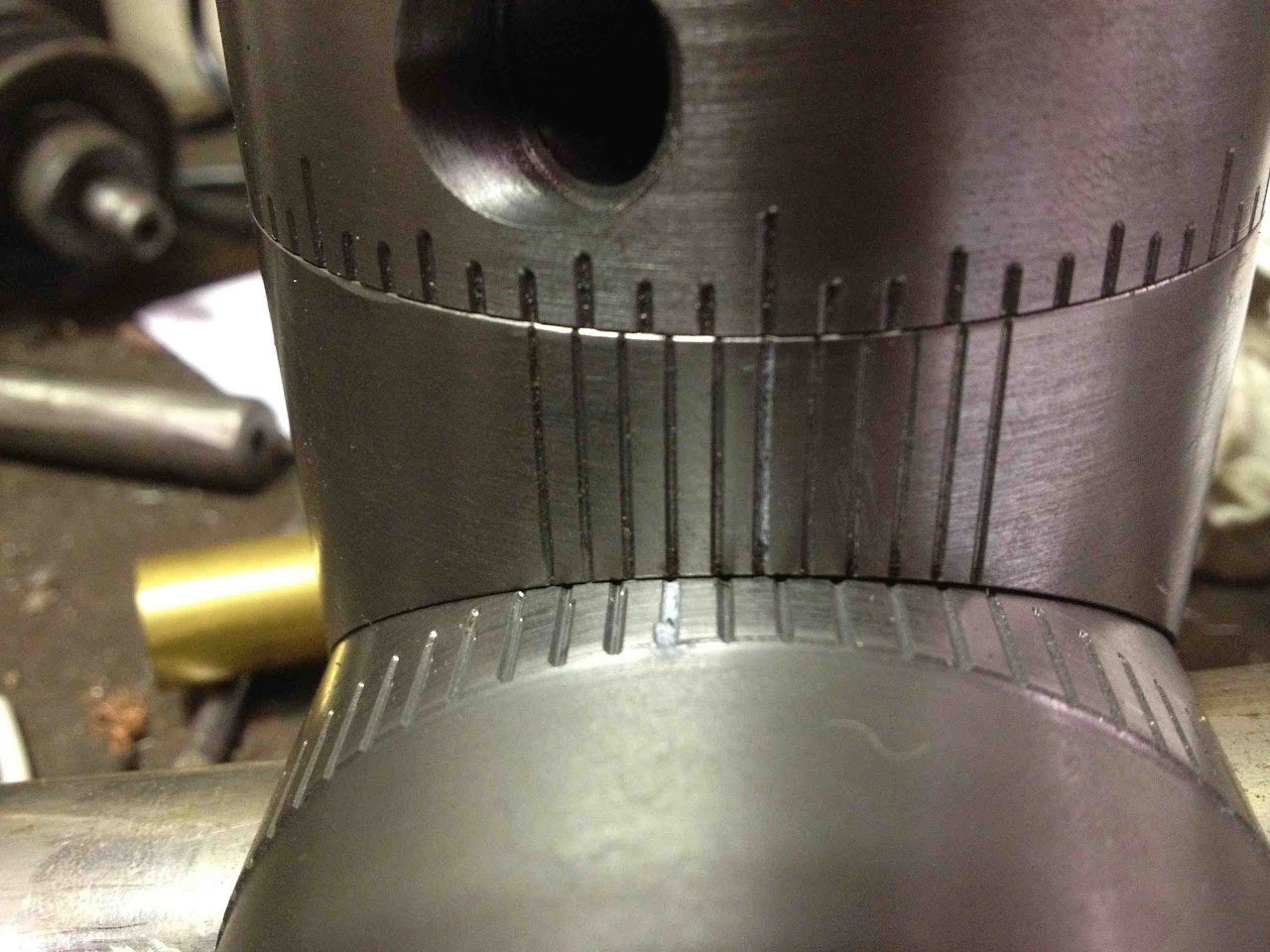

The work head was fabricated from some 3 inch cast iron rod I found some where. The cutting angle and clearance angles can be set to 1 deg directly from the verniers and to 1/2 deg by interpolation.

The work head rides on a 1 1/4 shaft that rotates on cast iron bushings and slides in and out to set your depth of cut. The assembly on the end of the shaft controls the in and out motion with a 20 tpi collar that rotates on the shaft so that the shaft rotation doesn't affect the depth of cut.

Some working drawings were made, more of an assembly drawing I guess but its a big file in dxf format so not sure how to post it.

Hope this helps.

Oh the tool post grinder is an old Dunmore. Worn but it gets the job done.

Greg