Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

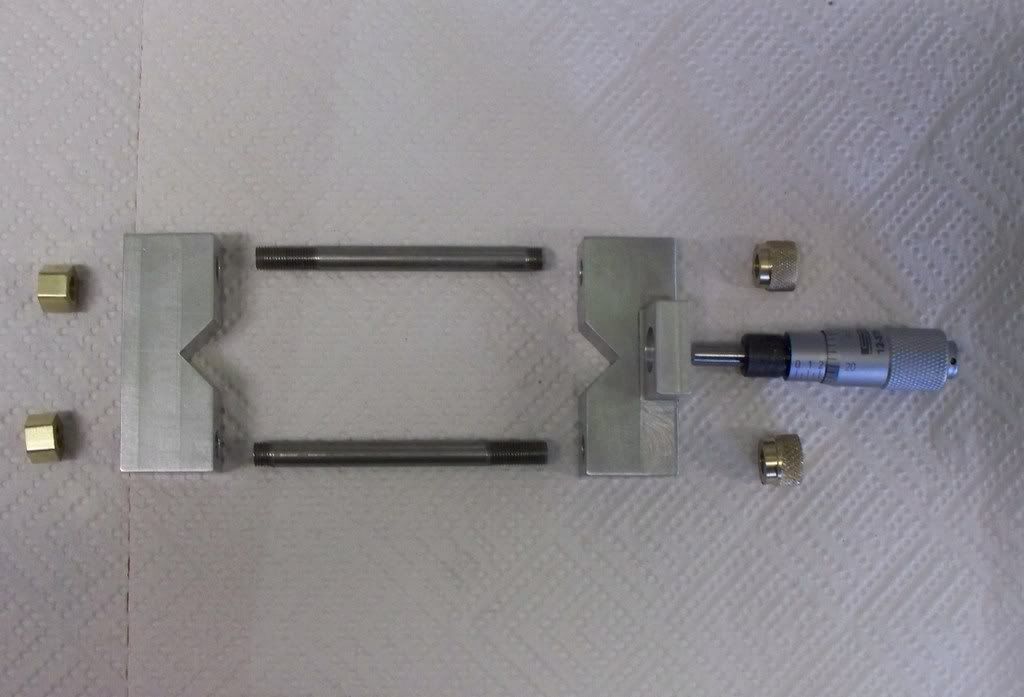

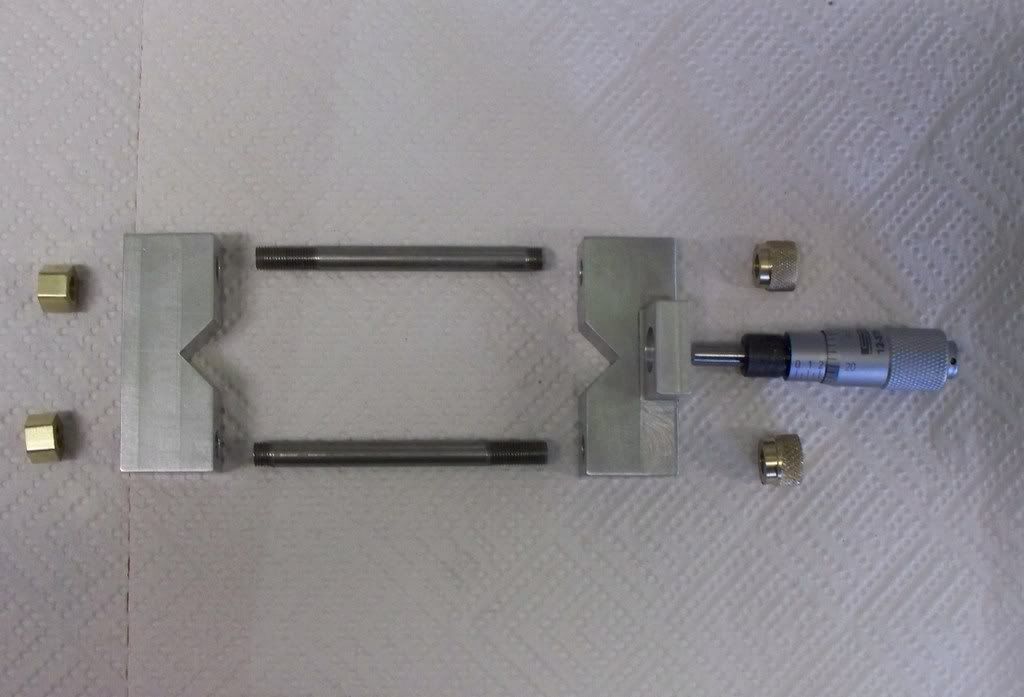

As part of my Seal engine build I need to inline bore the cylinder block. Whilst making the boring bar is relatively simple, setting the tool in clear increments of adjustment after each cut seemed a little more complicated. I needed a method of moving the tip of the cutting tool in steps that were measurable and raised this issue on my blog website. One response received included an article by Eddy Rebbe, who described his double clamp system incorporating a screw that moved the tool point. The article appeared in the May/June issue of MEW (Model Engineering Workshop) 1994.

I liked Eddies design but thought it could be simplified, and the level of accuracy of the tool increased by the fitting of a micrometer head. So out came the drawing paper and some scribbled designs were soon made. I also wanted to use the design process to help me get to grips with CAD. Using the Alibre free package I soon managed to get something drawn up and then it was into the workshop to make a start.

By a combination of building, back to design then building again, I arrived at the final design seen in the photos. It has fewer parts than Eddy Rebbes, so should be easier to construct. My version was made from materials in the waiting to be resized box (scrap!) the only item bought was the micrometer head from MSC/J&L (UK based) http://www.mscjlindustrial.co.uk/cgi/insrhm (reference SPU-12375H) and cost £17.87p. I have no link to this company other than buying the micrometer head from them but their delivery was swift and it is a nice item. No doubt there are other sources out there for similar items.

I got on to MSC/J&L from an advert they placed in the last issue of Model Engineer and if you order their catalogue be prepared to reinforce your table. Its massive, and from memory around 1,800 pages! I dont think there is anything engineering wise that they dont stock! I must take my hat off to you professionals out there. Some of the prices of top quality tooling is frightening

Now back to the tool. It didnt take too long to make and when finished I thought it would be nice to put it in a box to protect it. Perhaps its the fact that it has a micrometer head that led me to make its box. Bearing in mind I dont like woodwork you can see how much I wanted to protect it!

Over the next few days I shall get to use it and will post the results when I have them. If you want a copy of the plans please email me BUT they are my first attempt at producing drawings so be warned!!!

I liked Eddies design but thought it could be simplified, and the level of accuracy of the tool increased by the fitting of a micrometer head. So out came the drawing paper and some scribbled designs were soon made. I also wanted to use the design process to help me get to grips with CAD. Using the Alibre free package I soon managed to get something drawn up and then it was into the workshop to make a start.

By a combination of building, back to design then building again, I arrived at the final design seen in the photos. It has fewer parts than Eddy Rebbes, so should be easier to construct. My version was made from materials in the waiting to be resized box (scrap!) the only item bought was the micrometer head from MSC/J&L (UK based) http://www.mscjlindustrial.co.uk/cgi/insrhm (reference SPU-12375H) and cost £17.87p. I have no link to this company other than buying the micrometer head from them but their delivery was swift and it is a nice item. No doubt there are other sources out there for similar items.

I got on to MSC/J&L from an advert they placed in the last issue of Model Engineer and if you order their catalogue be prepared to reinforce your table. Its massive, and from memory around 1,800 pages! I dont think there is anything engineering wise that they dont stock! I must take my hat off to you professionals out there. Some of the prices of top quality tooling is frightening

Now back to the tool. It didnt take too long to make and when finished I thought it would be nice to put it in a box to protect it. Perhaps its the fact that it has a micrometer head that led me to make its box. Bearing in mind I dont like woodwork you can see how much I wanted to protect it!

Over the next few days I shall get to use it and will post the results when I have them. If you want a copy of the plans please email me BUT they are my first attempt at producing drawings so be warned!!!