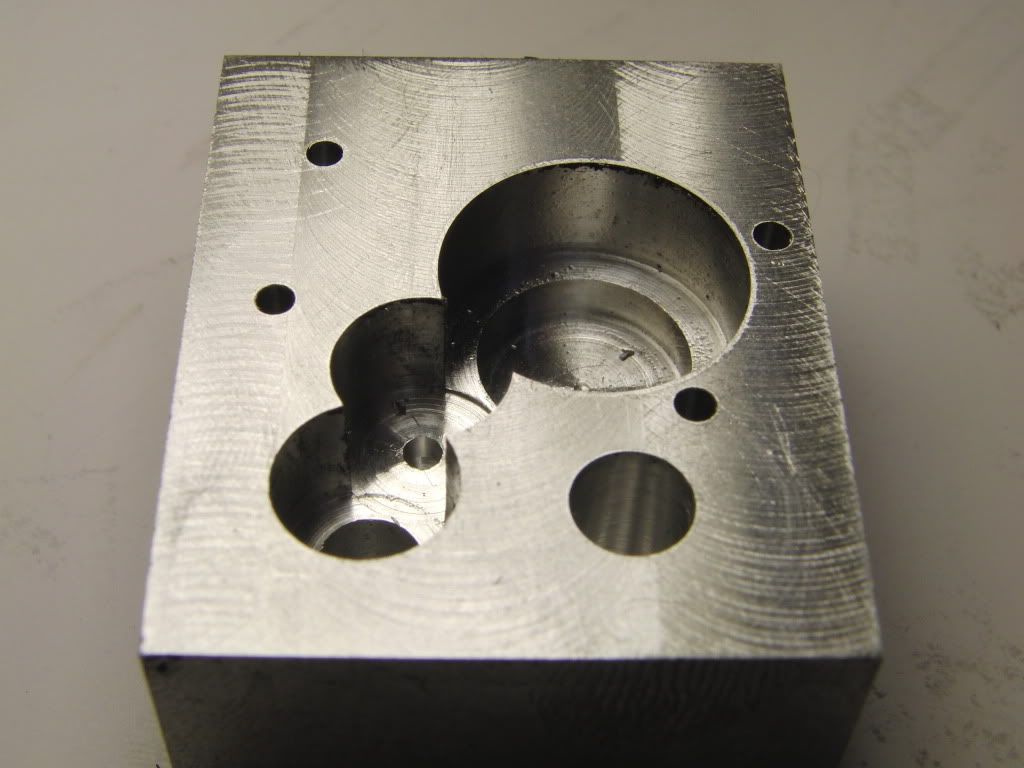

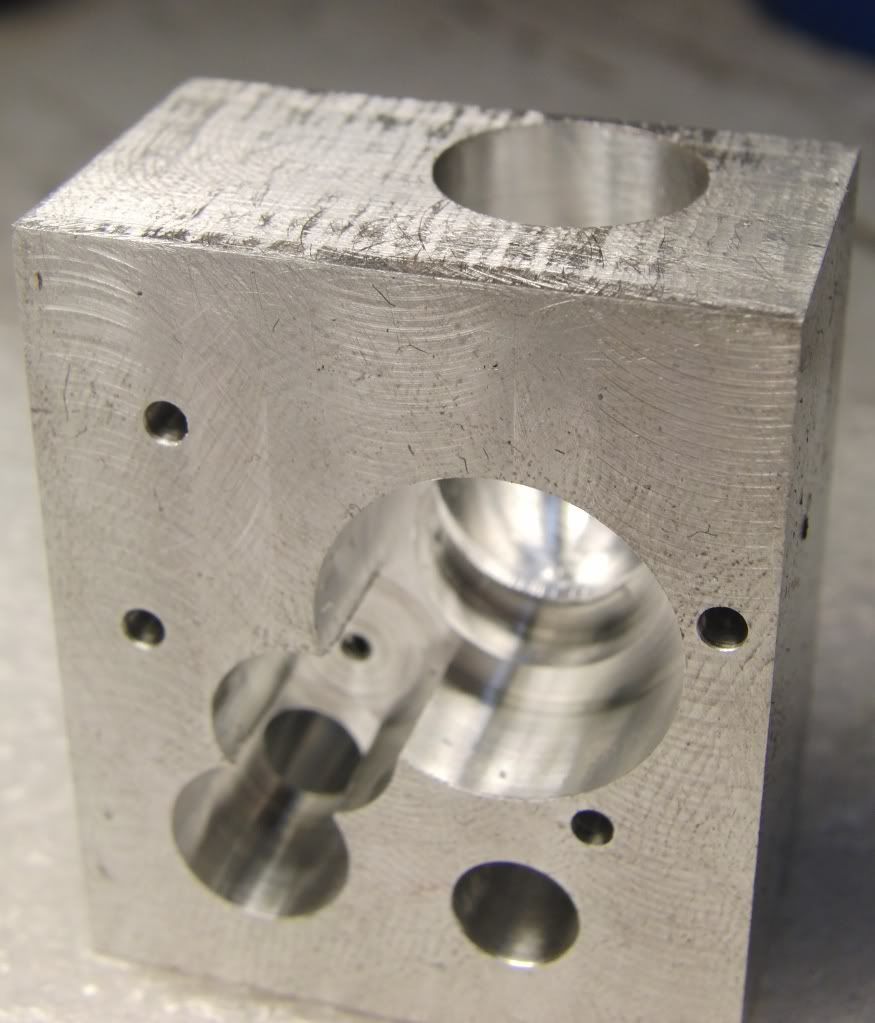

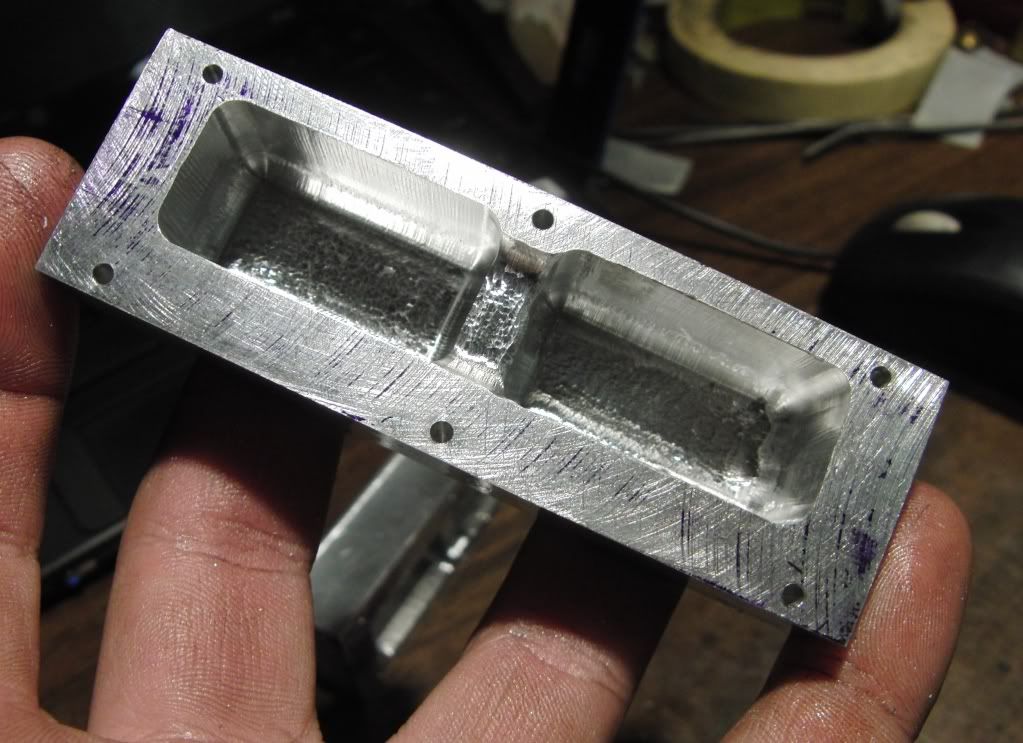

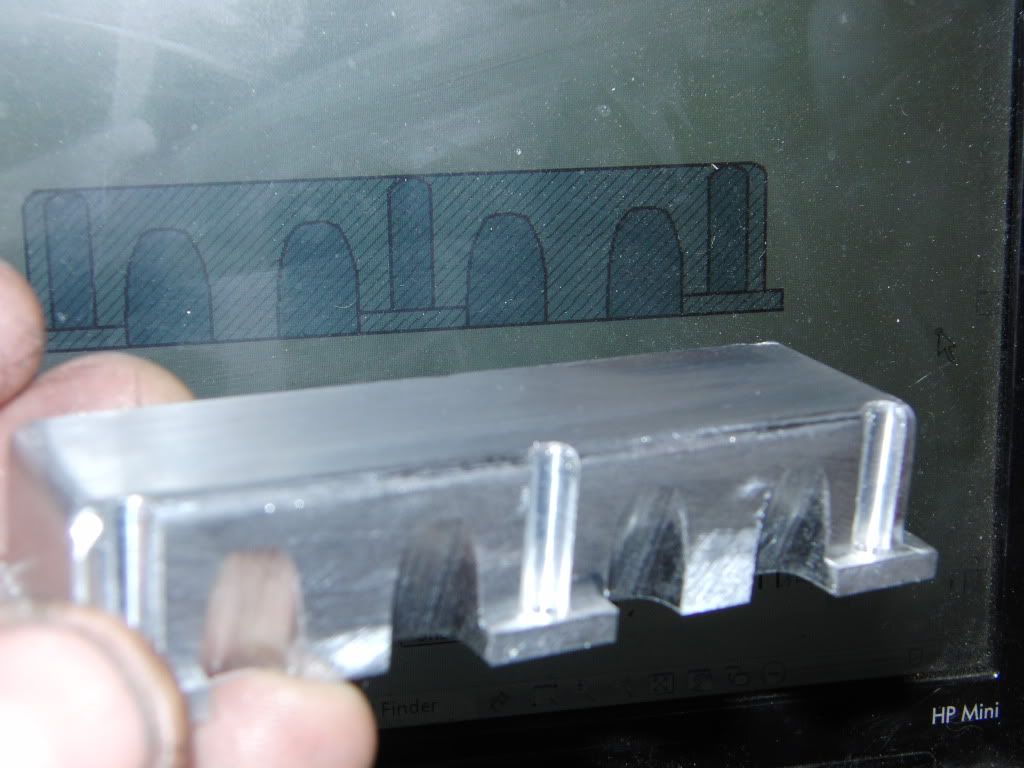

I finally pulled the trigger and started milling the water jackets.

I decided not mill them from the side and instead use Steve's Suggestion of using a key cutter.

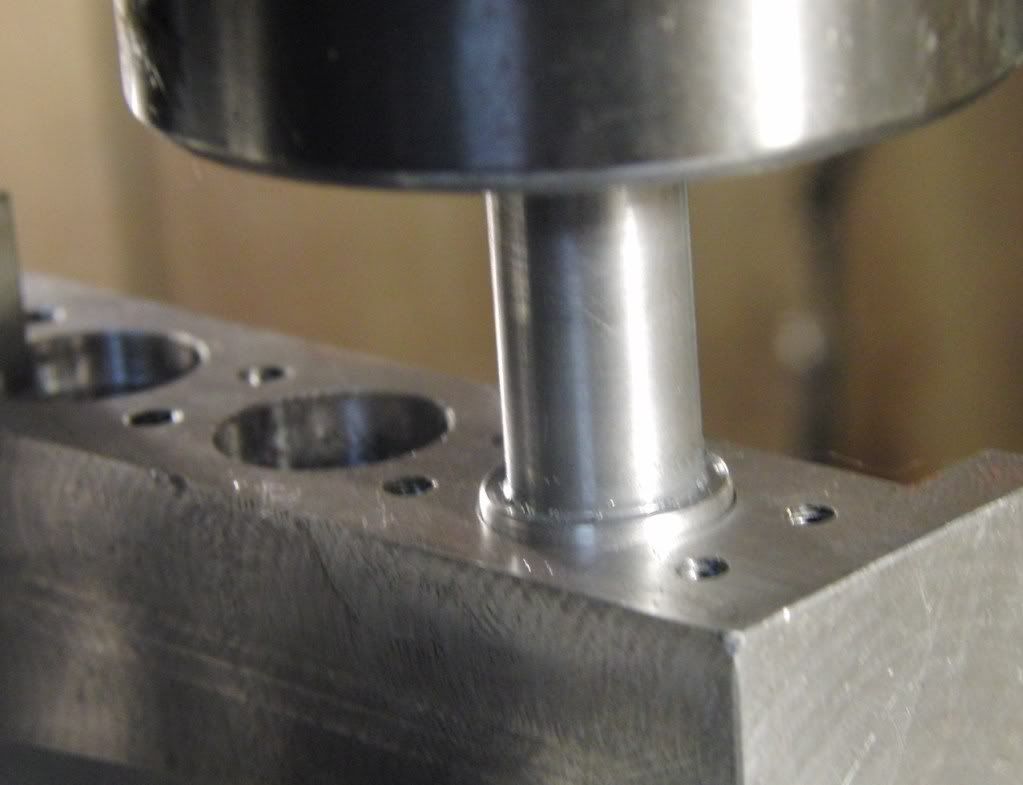

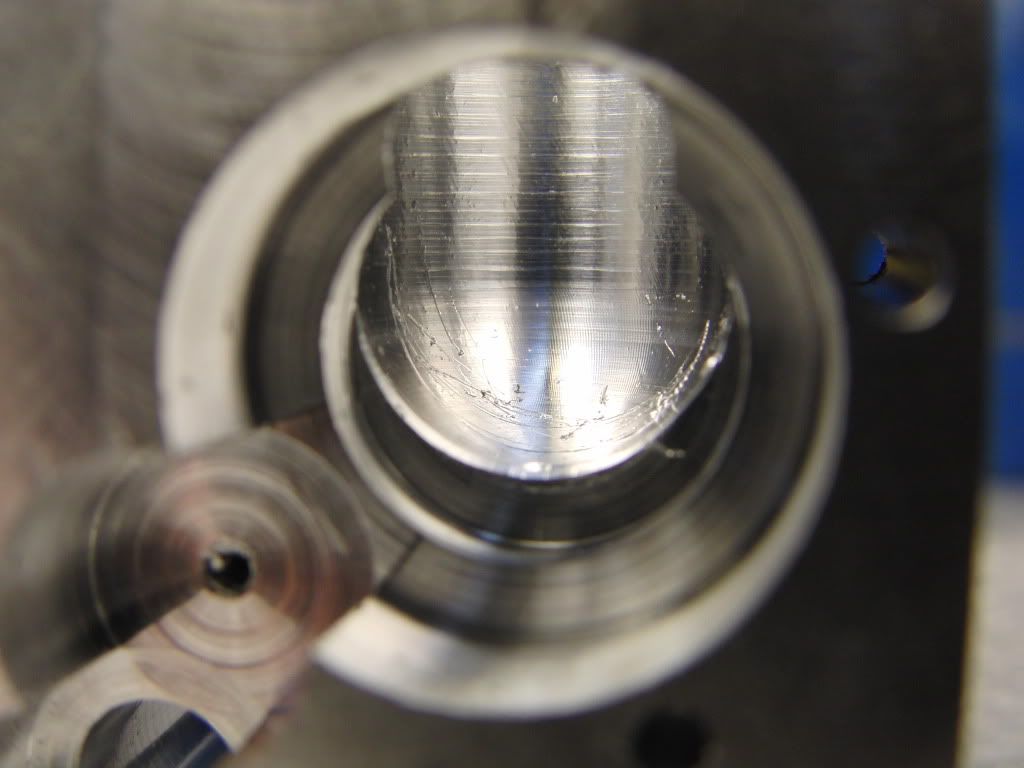

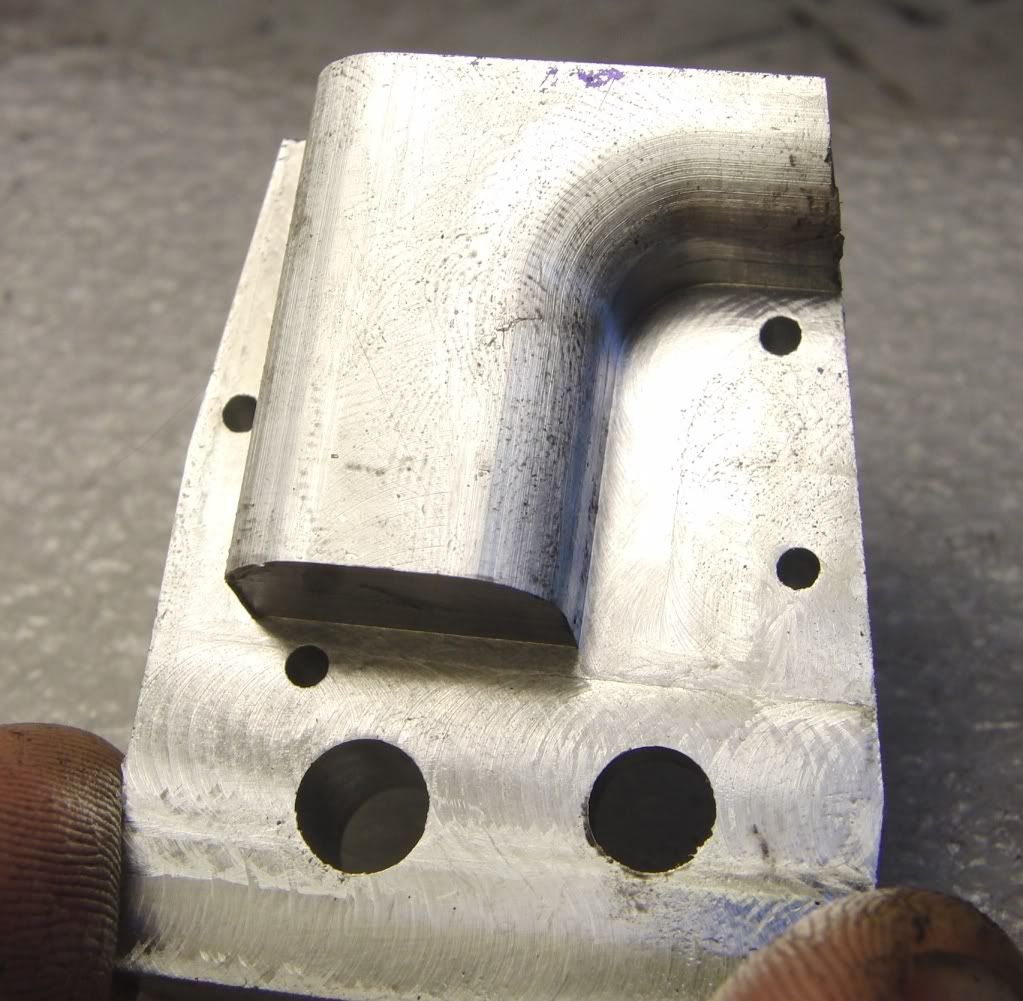

I had to make the key cuter since I did not have one to fit the bore.

It is made from 3/8" drill rod. You can see it below.

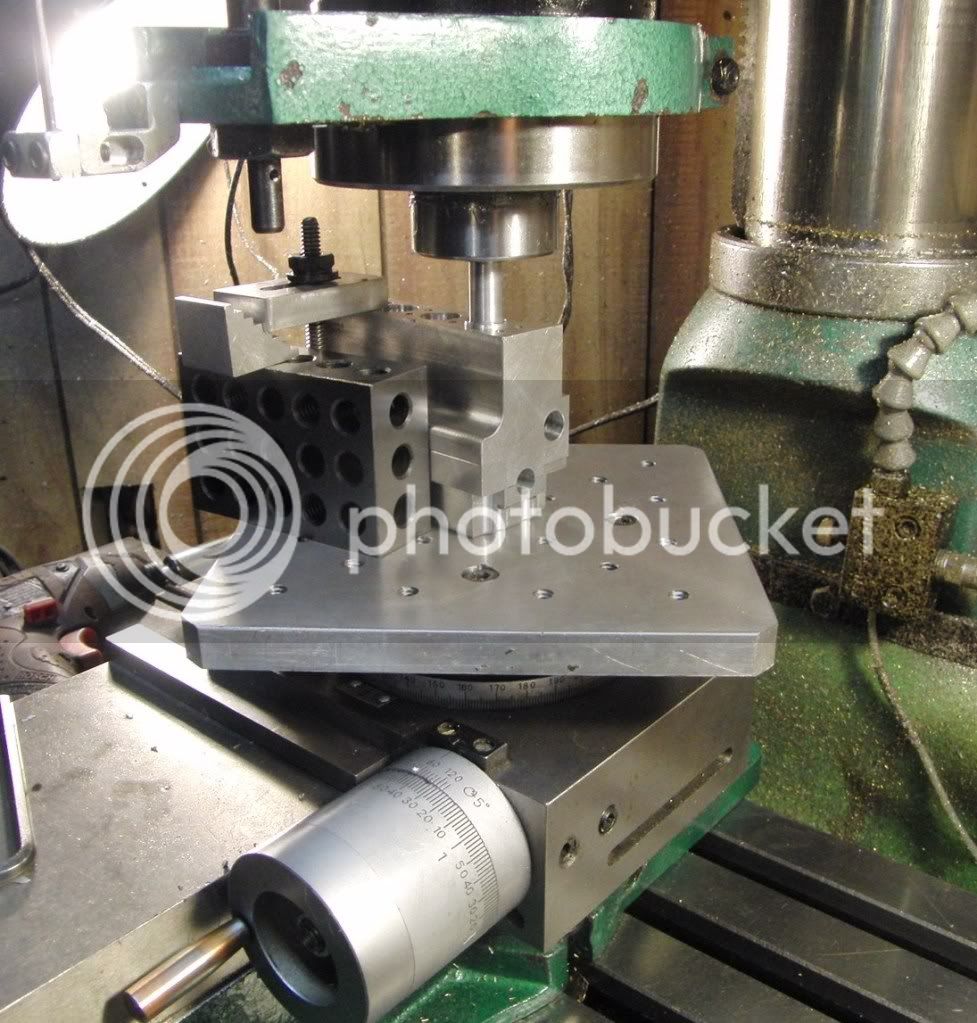

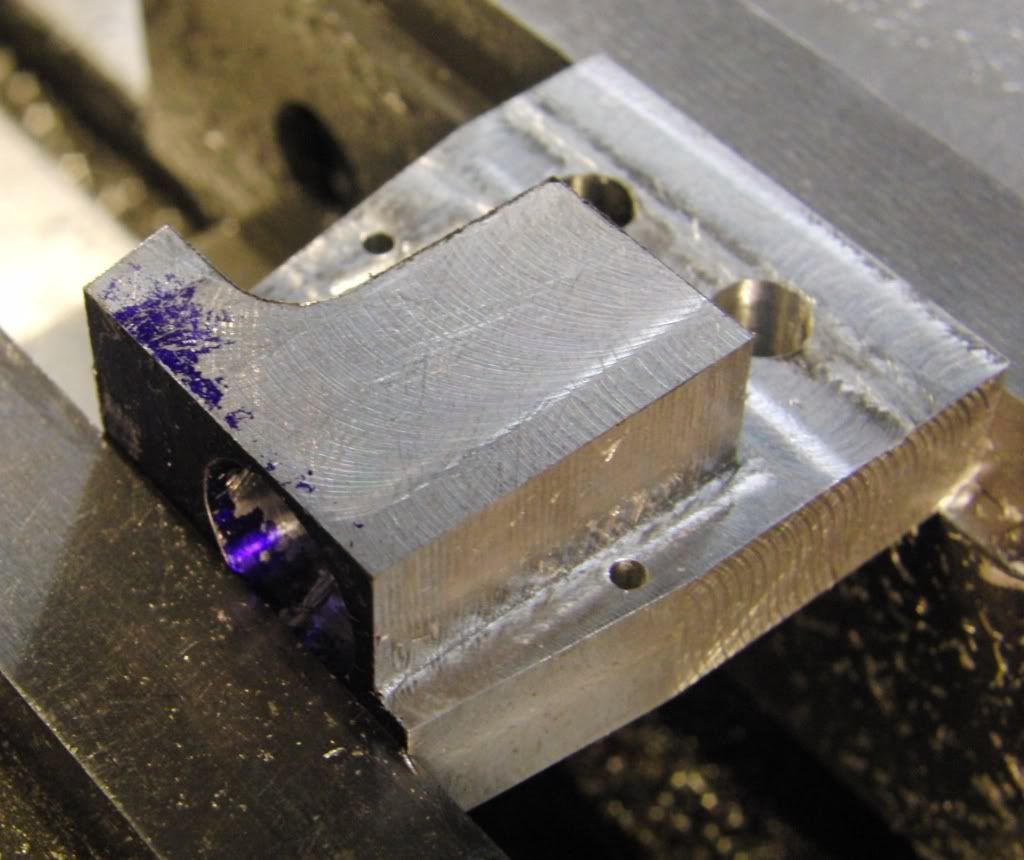

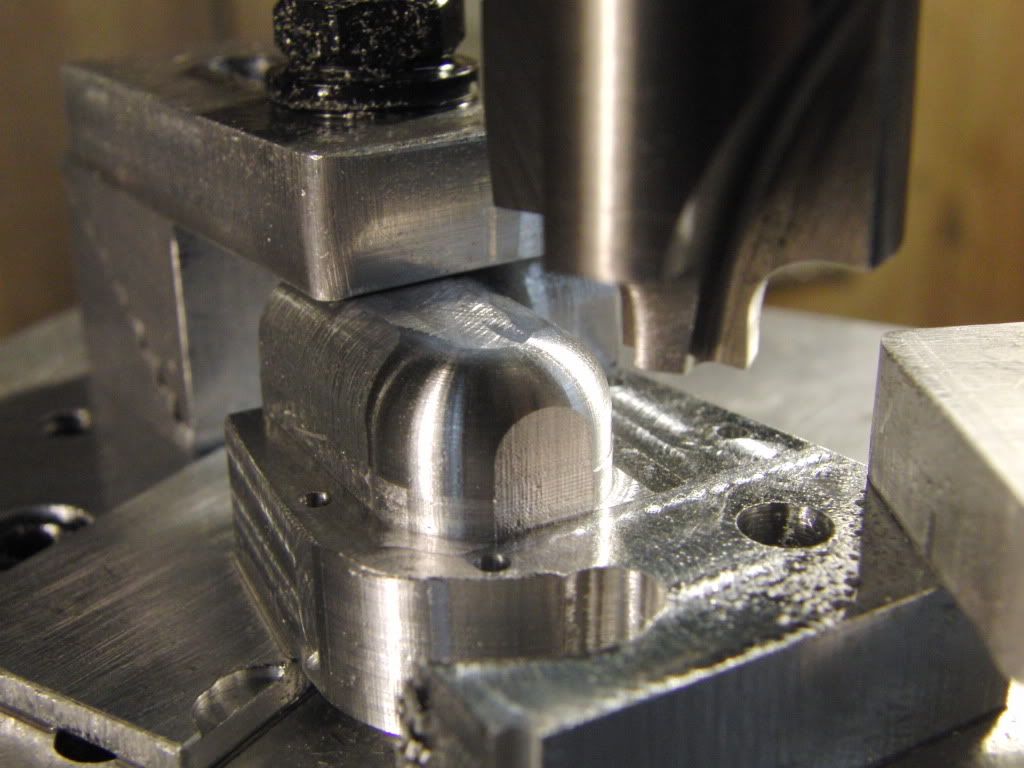

Next was to com up with a quick way to locate each bore on my rotary table.

I made a tooling plate for it awhile ago, so it was a matter of getting the R/T centered to the spindle, then locating each bore.

I made a slug out of aluminum with a 3/8" shank and a .5" large end.

I stuck that in a collet in the mill and put it in the bore of the first cylinder, while it was still in the bore I then clamped it in place.

Here is the setup.

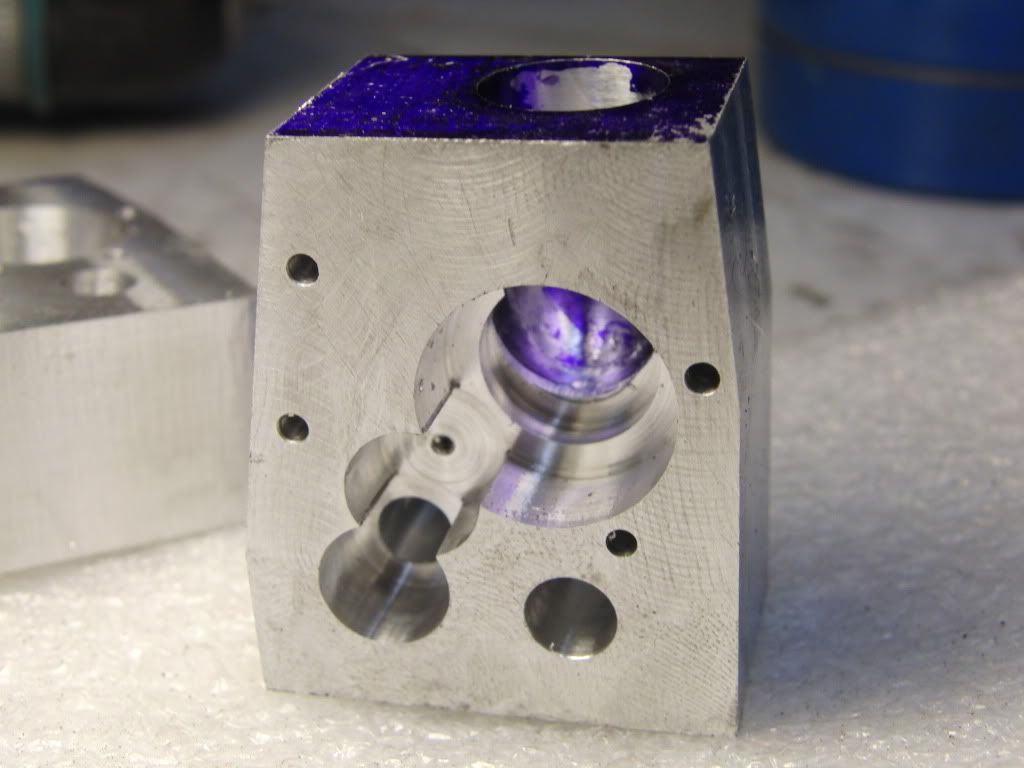

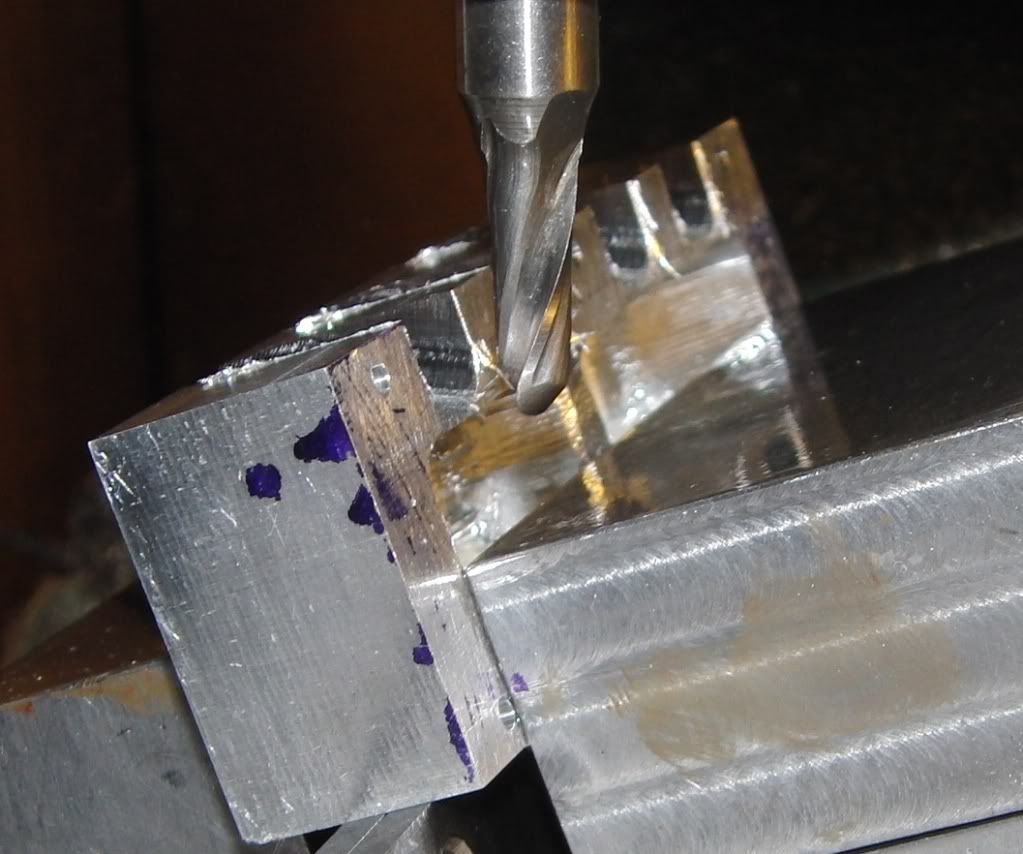

I used a small cordless drill to make turning the rotary table easier. I had to make 4 passes in each cylinder, at 72 cranks per revolution that would be 1152 cranks of that small wheel for each block. (No Thanks) the drill wil be nice.

I now need to decide where to Drill the holes.

I was thinking about drilling a hole from the back of the engine at the bottom of the water jacket (This would be the inlet) and then drilling a second hole from the front at the top of the water jacket (This would be the outlet) I was thinking this way the water will flow in from a low spot, travel around all the cylinder liners and then exit at the top, hopefully removing all the air in the process.

Kel